Multifunctional gear rotor bearing system testing apparatus

A gear rotor and test device technology, which is applied in mechanical bearing testing, machine gear/transmission mechanism testing, measuring devices, etc., can solve the problems of lack of test equipment and devices, and achieve simple structure, convenient installation, and various combinations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

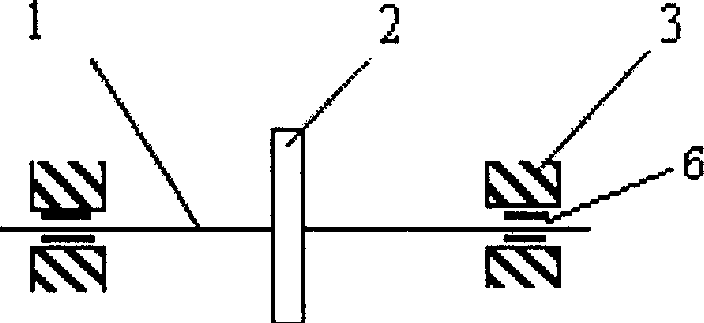

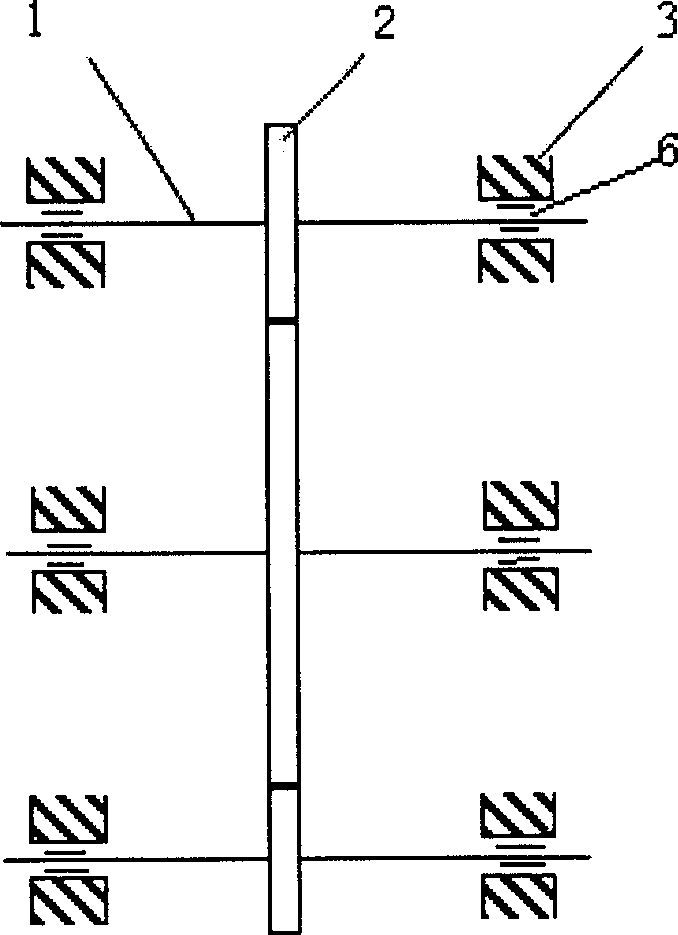

[0013] Such as figure 1 As shown, the multifunctional gear rotor bearing system test device is composed of transmission shaft 1, mass disc 2 (or gear), sliding bearing 6 (or rolling bearing) and bearing housing 3 (or frame, box). Above, through the expansion sleeve connection, install the mass disc or the gear 2, and install and support the sliding bearing or the rolling bearing 6 in the bearing seat 3 at both ends of the transmission shaft 1, to form various single-span rotor-bearing subsystems.

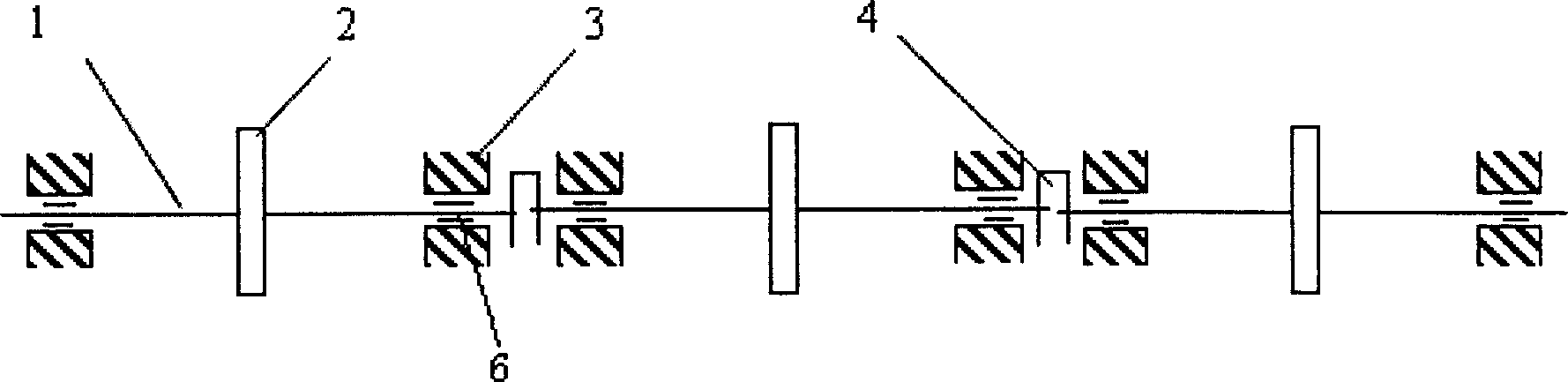

[0014] Such as figure 2 As shown, more than two single-span rotor-bearing subsystems are connected in series through various couplings 4 to form a multi-span rotor-bearing system. It can be used to study the dynamic characteristics of steam turbines and water turbines, such as stability, critical speed, rotor misalignment, mass imbalance, the influence of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com