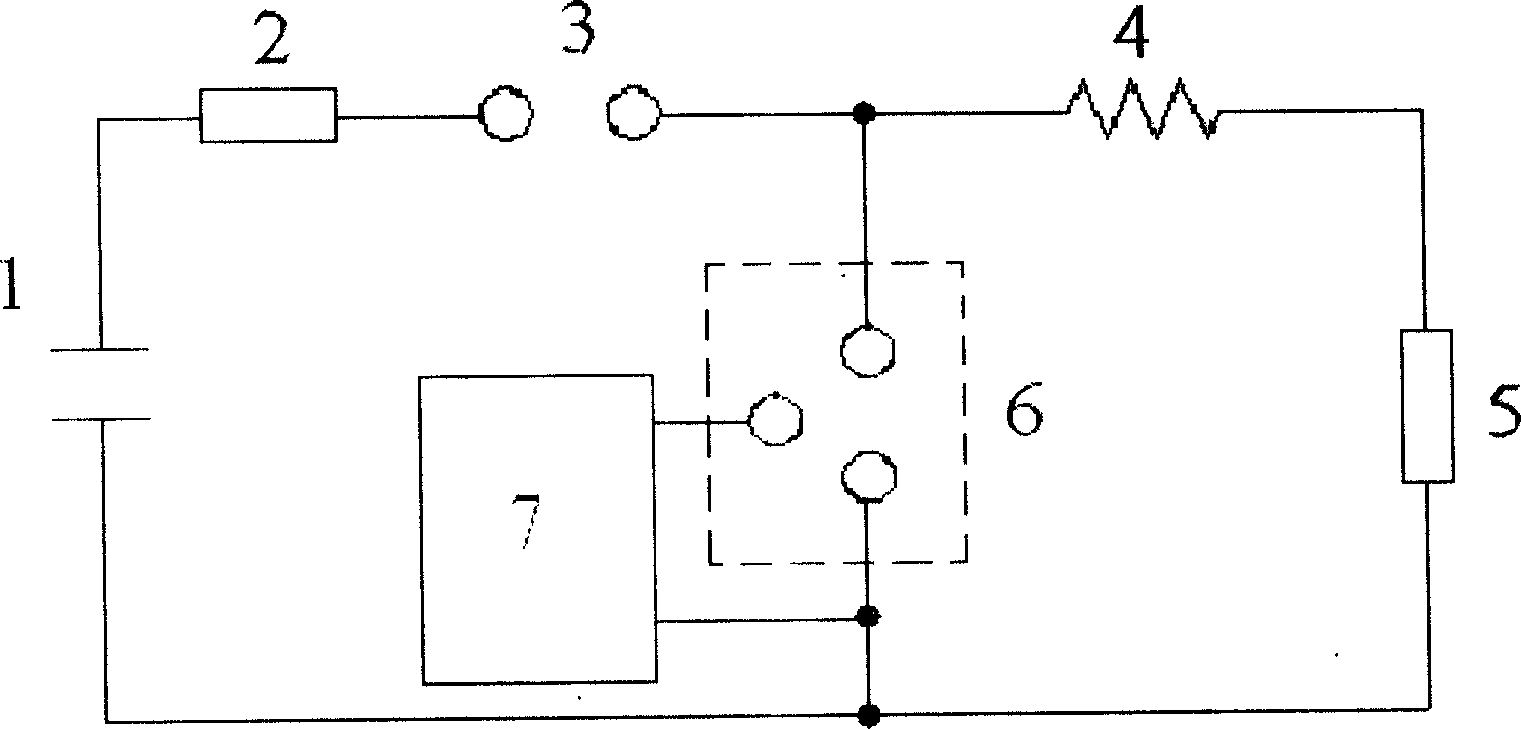

10/350 shock current system for air or vacuum crowbar switch

An inrush current and switching technology, applied in the field of overvoltage protector inrush systems, can solve the problems of poor stability and reliability of CROWBAR switches, bulky CROWBAR switches, difficult adjustment and coordination, etc., to ensure reliability and stability, and steep pulse rise. Effect of time and large flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

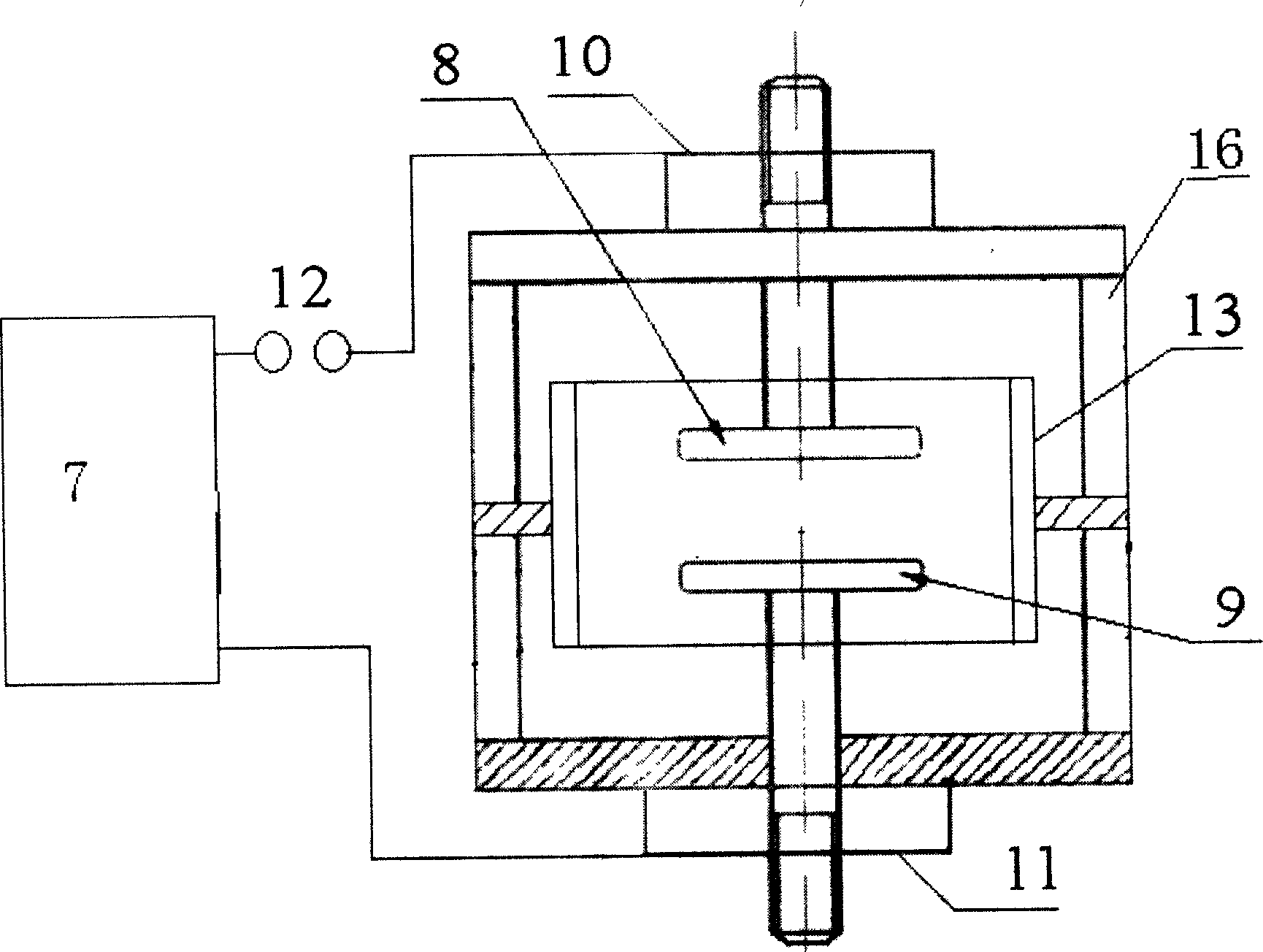

[0019] Embodiment 1: see figure 2 , The CROWBAR switch 6 includes a movable electrode 8 and a fixed electrode 9 arranged in an insulating shell 16, wherein one movable electrode 8 can be adjusted according to the discharge voltage, and the working environment of the electrodes 8 and 9 can be air or 10 -5 Pa~10 -2 The vacuum environment of Pa, if working in the air environment, the CROWBAR switch 6 is made of sound-absorbing material; if working in a vacuum environment, the CROWBAR switch 6 is made of airtight insulating material; A bellows that not only ensures that the electrodes of the switch are in the insulating casing 16 but also enables the electrodes to move. The connection relationship between the CROWBAR switch 6 and the trigger system is: one end of the trigger system 7 is connected to the connection terminal 10 of the movable electrode 8 of the CROWBAR switch 6 , and the other end is connected to the connection terminal 11 of the fixed electrode 9 of the CROWBAR s...

Embodiment 2

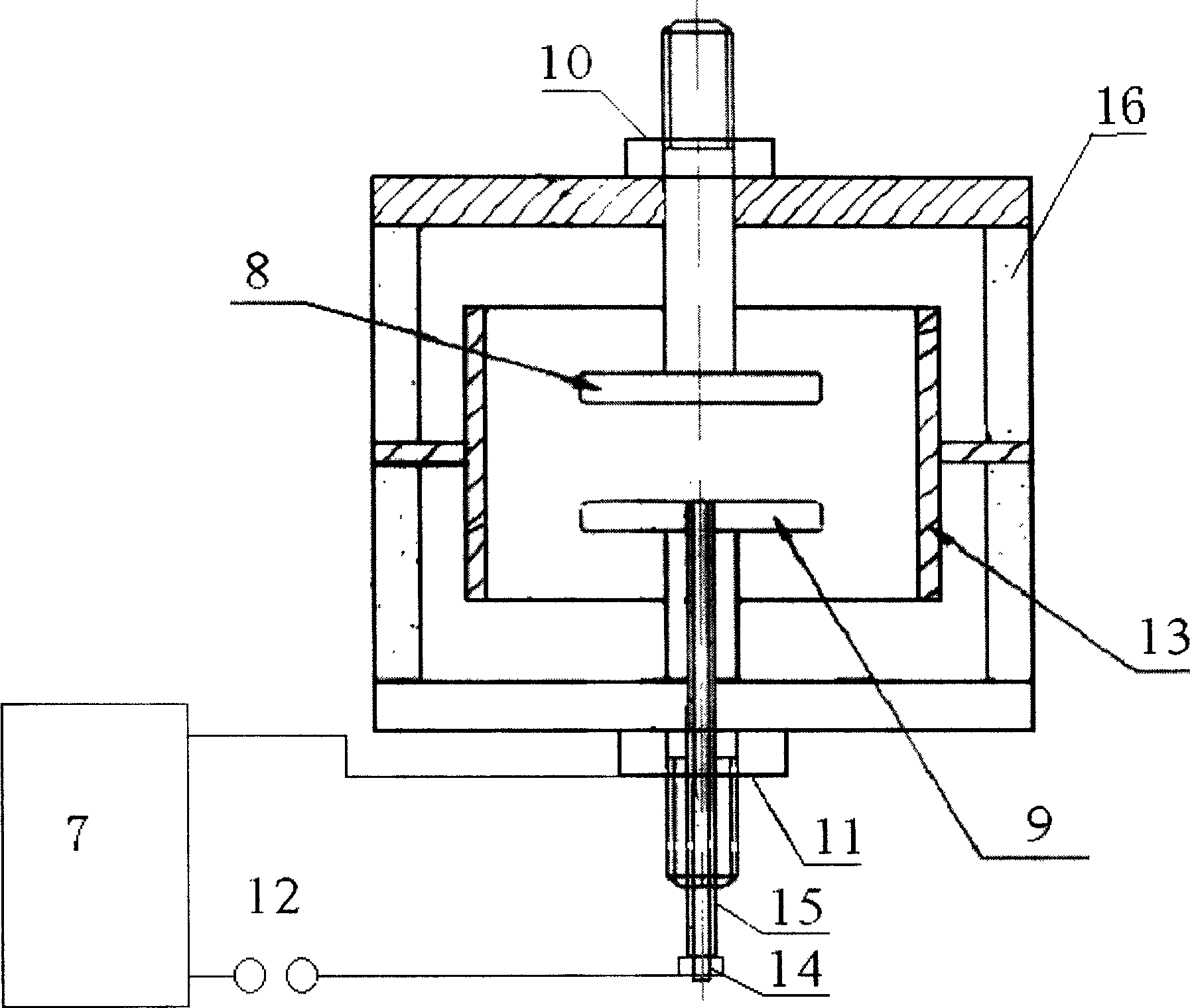

[0021] Example 2: see image 3 , the main discharge electrode and the trigger electrode of the CROWBAR switch 6 are an integral three-electrode structure, wherein the trigger electrode 14 is embedded in the center of the fixed electrode 9, and is isolated from the fixed electrode 9 by an insulating ceramic tube 15, and the trigger electrode 14 can also be placed in a fixed side of the electrode 9. The working environment can be air or 10 -5 Pa~10 -2The vacuum environment of Pa, if working in the air environment, the CROWBAR switch 6 is made of sound-absorbing material; if working in a vacuum environment, the CROWBAR switch 6 is made of airtight insulating material, and the connection relationship between the CROWBAR switch 6 and the trigger system is: trigger One end of the system 7 is connected to the trigger electrode 14 of the CROWBAR switch 6 , and the other end is connected to the connection terminal 11 of the fixed electrode 9 of the CROWBAR switch 6 . In order to pre...

Embodiment 3

[0022] Embodiment 3: see Figure 4 , the main discharge electrode and the trigger electrode of the CROWBAR switch 6 are an integral three-electrode structure, but the trigger electrode 14 is placed between the movable electrode 8 and the fixed electrode 9, and the trigger electrode 14 can be ring-shaped, or disc-shaped or column-shaped, CROWBAR switch 6 line connection relationship and trigger work process with the embodiment 2.

[0023] The present invention is different from the most notable feature of the existing 10 / 350 impulse current test system in that it only needs to adjust the gap distance between the fixed electrode 8 and the movable electrode 9 of the CROWBAR switch 6 (the gap distance can be changed between 0-120mm (air environment) or between 0 and 20mm (vacuum environment)), the maximum withstand voltage of the CROWBAR switch can be as high as 200kV or more, and it can ensure that the voltage between the movable electrode [8] and the fixed electrode [9] is very ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com