Nano powder capture method

A nano-powder and powder technology, which is applied in the field of above-grade powder, can solve problems such as environmental pollution and emissions

Inactive Publication Date: 2006-05-10

IND TECH RES INST

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention can capture the nano-powders in the gas containing powders with different particle sizes by adjusting the control conditions such as the rotational speed of the rotating packed bed and the amount of washing liquid sprinkled, so that the nano-industry can safely and effectively collect the produced The nano-powder produced by the company may solve the problem of environmental pollution caused by the emission of sub-micron particles in the existing high-tech industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0032] rotating packed bed

[0033] Dust particle size

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

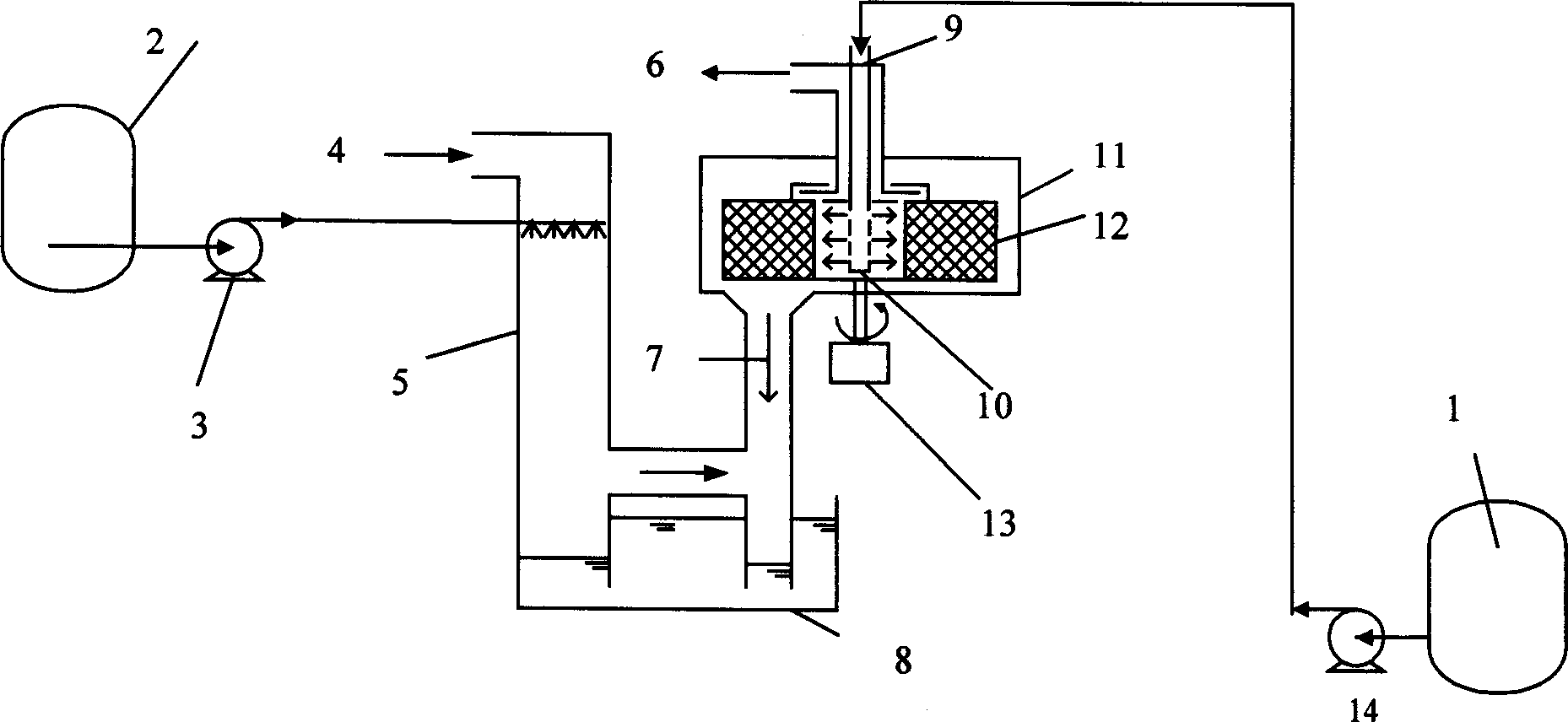

The invention relates to a method for catching the powder whose diameter is than nanometer grade, which comprises: the first step that increasing the diameter of gas with nanometer powder exhausted by nanometer powder production and burning process; and the second step that guiding it into rotary packed bed. Wherein, the first step can mix the gas with mist drip or vapor, via the impact between nanometer powder and mist drip or vapor and the condensation nucleus as nanometer powder to process the nucleus condensation growth to increase the diameter of nanometer powder; and the second step uses the micro-drip generated by rotary packed bed and the amputation function of bed to collect the particle with increased diameter via centrifugal force. And the first step can be processed in said rotary packed bed, while the gas with nanometer powder is directly guided into said rotary packed bed for a long time.

Description

technical field [0001] The present invention relates to a method for collecting powders with a particle size above the nanometer level, in particular to a method of using a rotating packed bed to discharge the gas containing nano-powder from the manufacturing process of nano-powder, or other gases containing nano-powder discharged from the combustion process. A method of trapping gas from nanopowders. Background technique [0002] Nanopowders are often found in the delivery gas of nanomaterials or nanocomponents, or in the gas emitted by the combustion process of substances. The particle size of these nanopowders is very small (several nanometers to tens of nanometers) and cannot be collected by common powders. Method - such as cyclone dust collector, electrostatic precipitator, bag filter and other equipment to effectively supplement collection. [0003] In recent years, the research and application of rotating packed beds have solved many problems that are difficult to so...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D47/00

Inventor 林佳璋徐树刚刘文宗曾益民

Owner IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com