Numerical control machine tool water cooling and scrap discharging system

A CNC machine tool and water-cooling technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of secondary damage of chips, inability to complete chip cooling, and inability to discharge chips in time, so as to prevent Small chips damage the machine tool, real-time efficient operation, reliable principle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

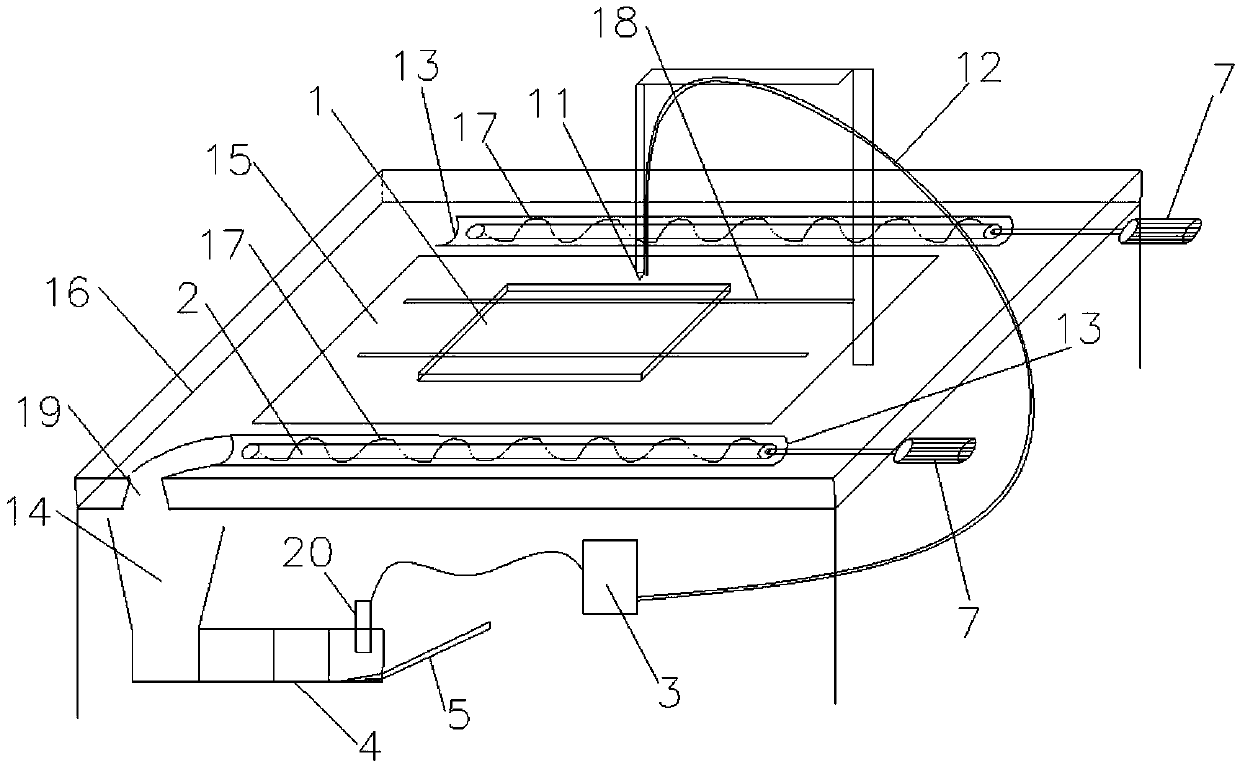

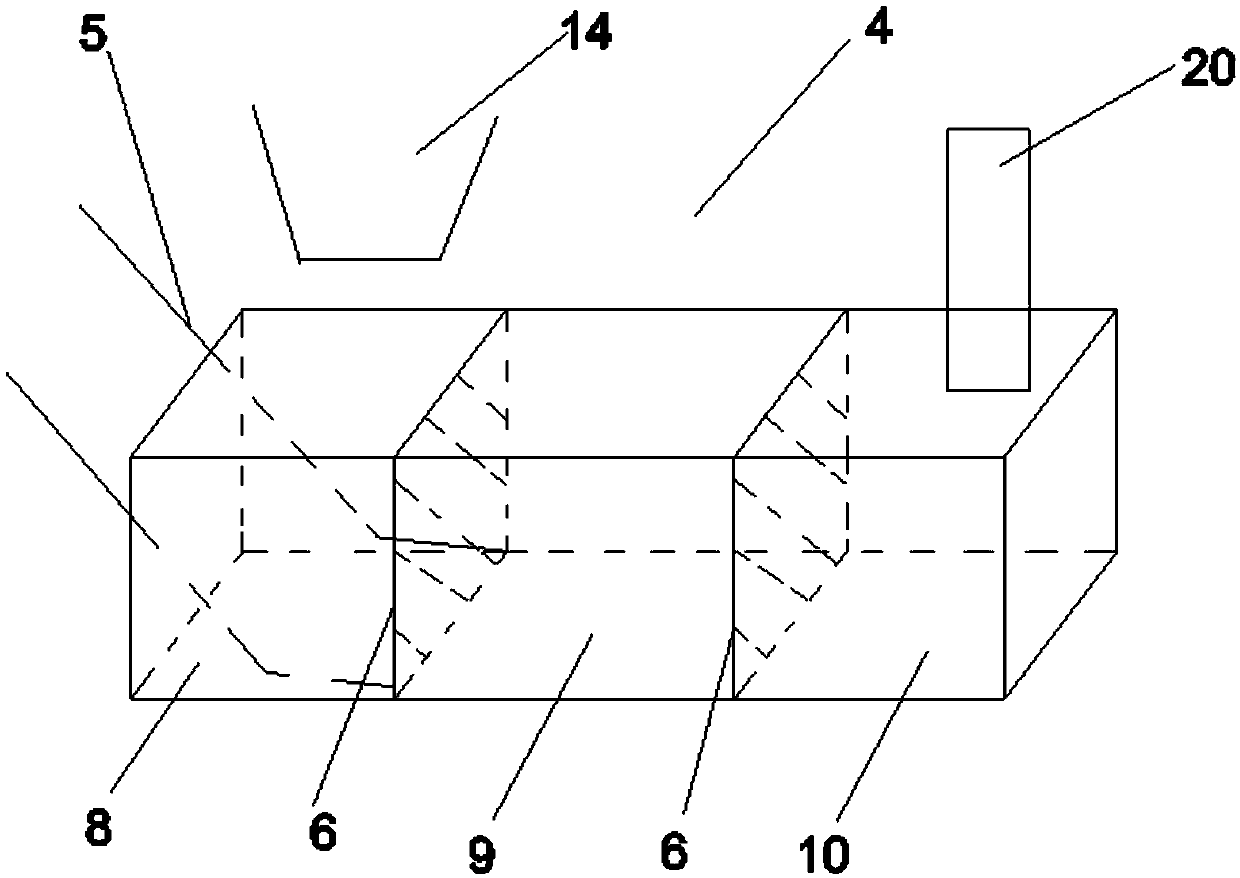

Embodiment 1

[0012] The main configuration of the CNC machine tool water-cooled chip removal system involved in this embodiment includes a workbench 1, a chip removal dragon 2, a cooler 3, a water tank 4, a conveyor belt 5, a filter screen 6, a keel motor 7, a cooling box 8, a filter box 9, Circulation box 10, faucet 11, cold water pipe 12, chip removal groove 13, material inlet 14, chip removal table 15, machine tool chassis 16, advancing thread 17, guide rail 18, chip removal port 19, pumping motor 20; chip removal table 15 is laid flat on the upper center of the machine tool chassis 15, and the center line of the top surface of the chip removal table 15 has an inclined slope downward to the left and right bottom edges. slide into the chip removal groove 13; a workbench 1 is arranged above the chip removal table 15, and the workbench 1 with a cuboid steel structure is slidingly connected with the chip removal table 15; There are two semi-cylindrical chip removal grooves 13, and a chip re...

Embodiment 2

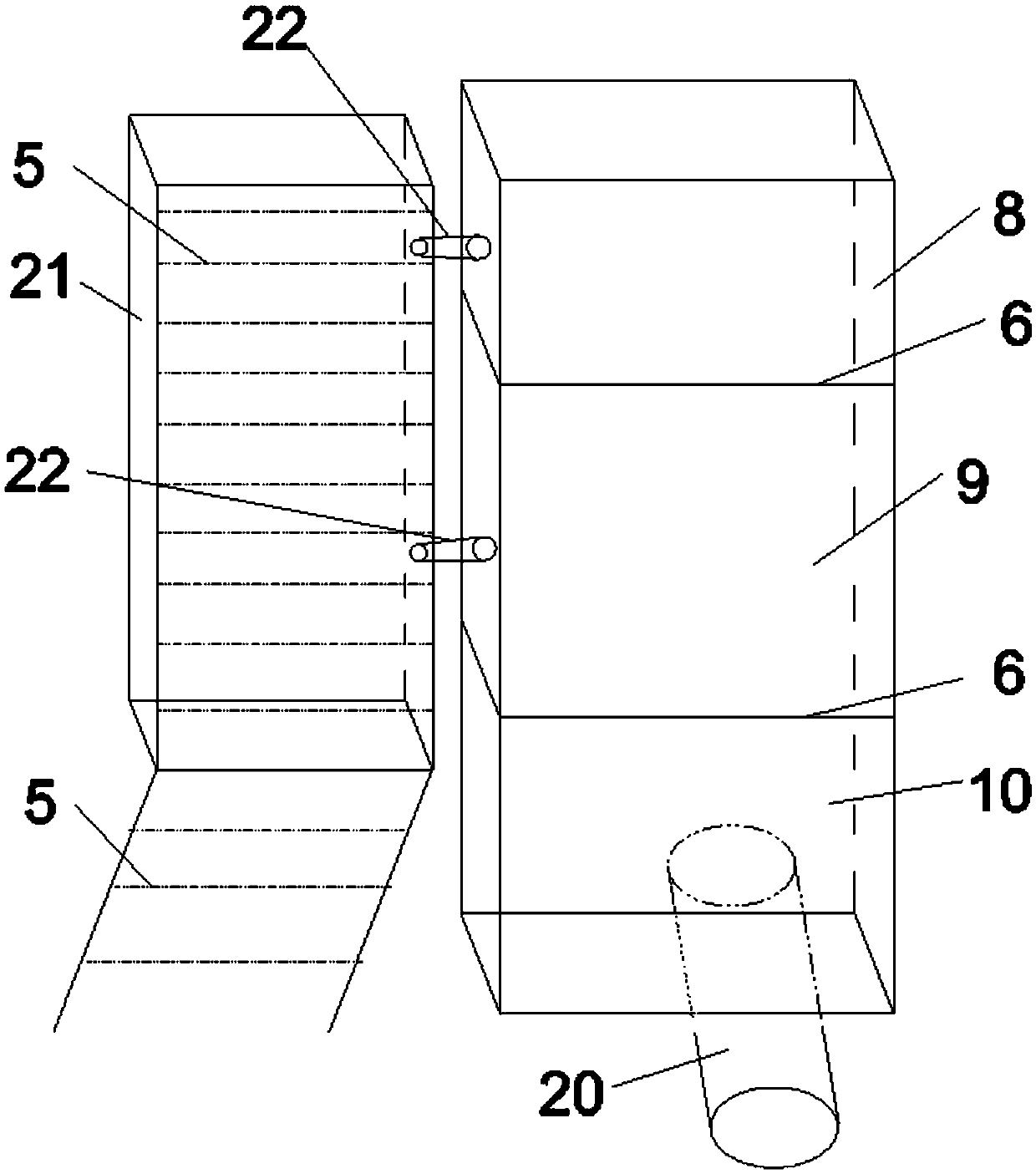

[0016] The main configuration of the CNC machine tool water-cooled chip removal system involved in this embodiment includes a workbench 1, a chip removal dragon 2, a cooler 3, a water tank 4, a conveyor belt 5, a filter screen 6, a keel motor 7, a cooling box 8, a filter box 9, Circulation box 10, faucet 11, cold water pipe 12, chip removal groove 13, collection box 21, chip removal table 15, machine tool chassis 16, advancing thread 17, guide rail 18, chip removal port 19, pumping motor 20; chip removal table 15 Tiling is set in the center of the upper part of the machine tool chassis 15, and the center of the top surface of the chip removal table 15 has an inclined slope to the left and right bottom edges, with a slope of 1-30°, so that the chips slide to the sides of the chip removal table 15 and enter the chip removal In the groove 13; above the chip removal table 15, a workbench 1 is arranged, and the workbench 1 of cuboid steel structure is slidingly connected with the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com