Cutting device for thin metallic plate

A cutting device, metal technology, applied in the direction of shearing device, shearing machine accessory device, pipe shearing device, etc., can solve the problems of damaged tools, large burrs, etc., and achieve the effect of reducing the occurrence of burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

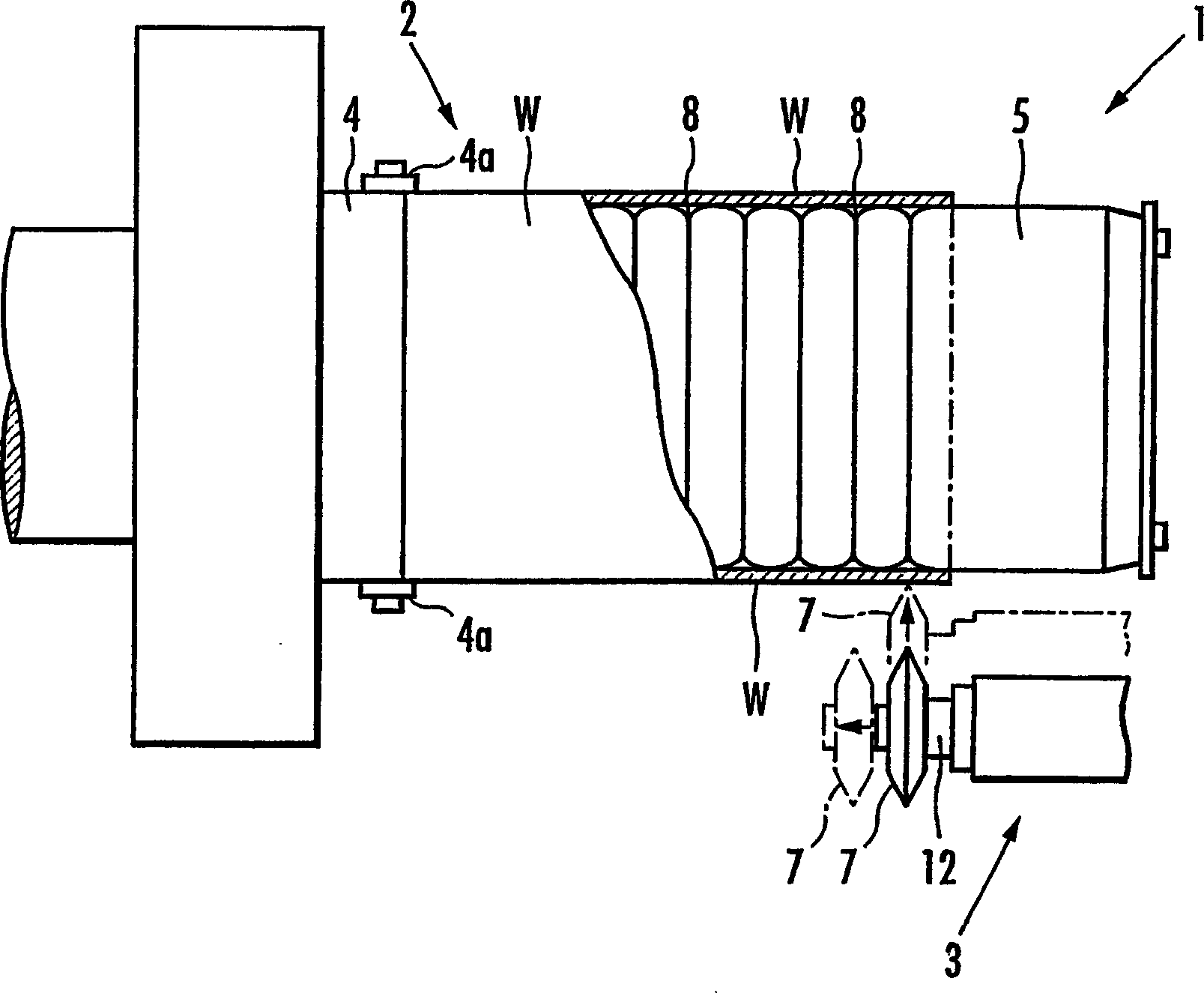

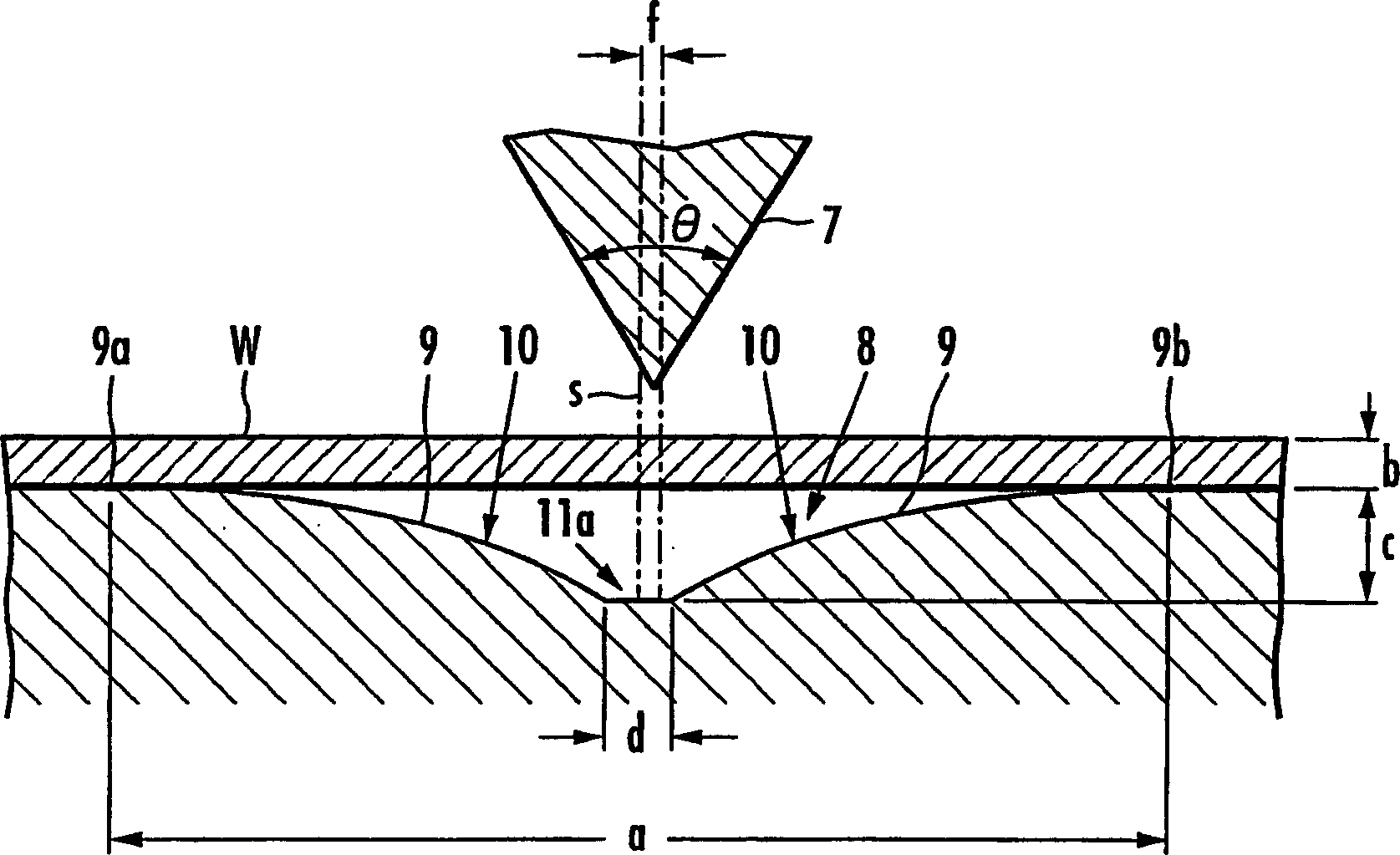

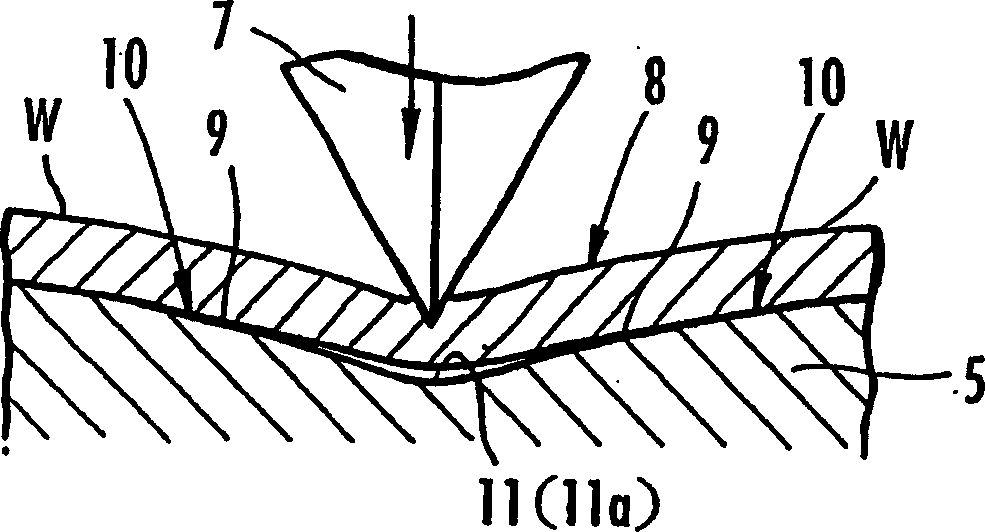

[0037] figure 1 The cutting device 1 according to the present embodiment is a metal ring for manufacturing a continuously variable transmission belt (not shown) by cutting a metal drum W in a ring-cut shape at a predetermined width. The above-mentioned drum W is formed by forming a rectangular flat thin plate of ultra-high strength steel into a cylindrical shape, and then joining both end edges by butt welding.

[0038] The cutting device 1 of the present embodiment, as figure 1 As shown, it is composed of a roll supporting mechanism 2 that supports the above-mentioned roll W, and a cutting mechanism 3 that cuts the roll W.

[0039] The above-mentioned roller supporting mechanism 2 is provided with: a supporting shaft 4, which is rotated by a rotation drive mechanism not shown in the figure; Contact tools for internal contact.

[0040] The above-mentioned support tool 5, such as figure 1 As shown, metal is formed into a cylindrical shape, and a plurality of grooves 8 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com