Method for measuring material critical non-corrosion air concentration value

A technology of aeration concentration and gas, which is applied in the field of measuring corrosion-free parameters of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The air hole plate is made of plexiglass with a thickness of 3 mm, the air hole diameter is 0.15 mm, the opening rate is 49%, and the plum blossom shape is arranged.

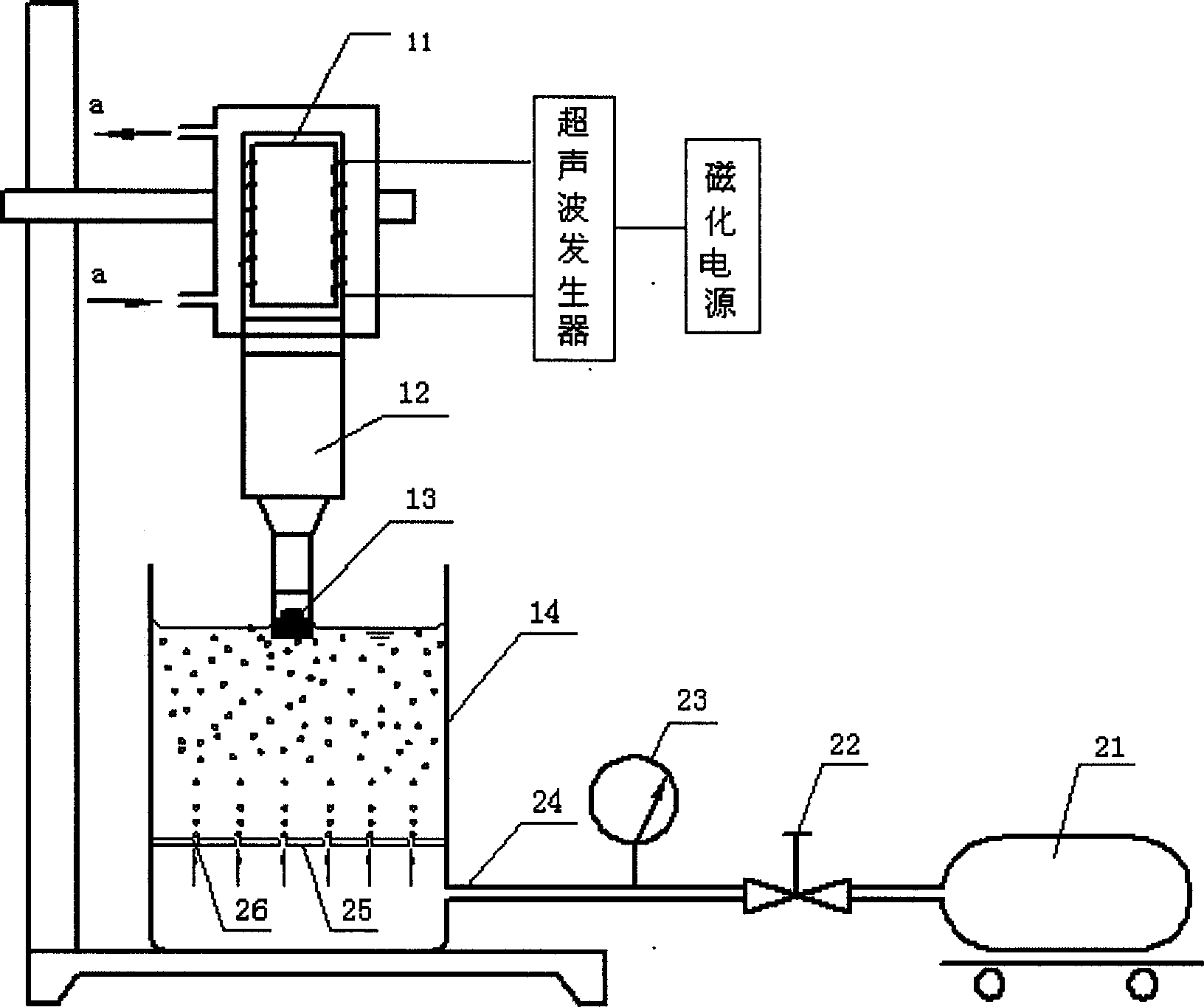

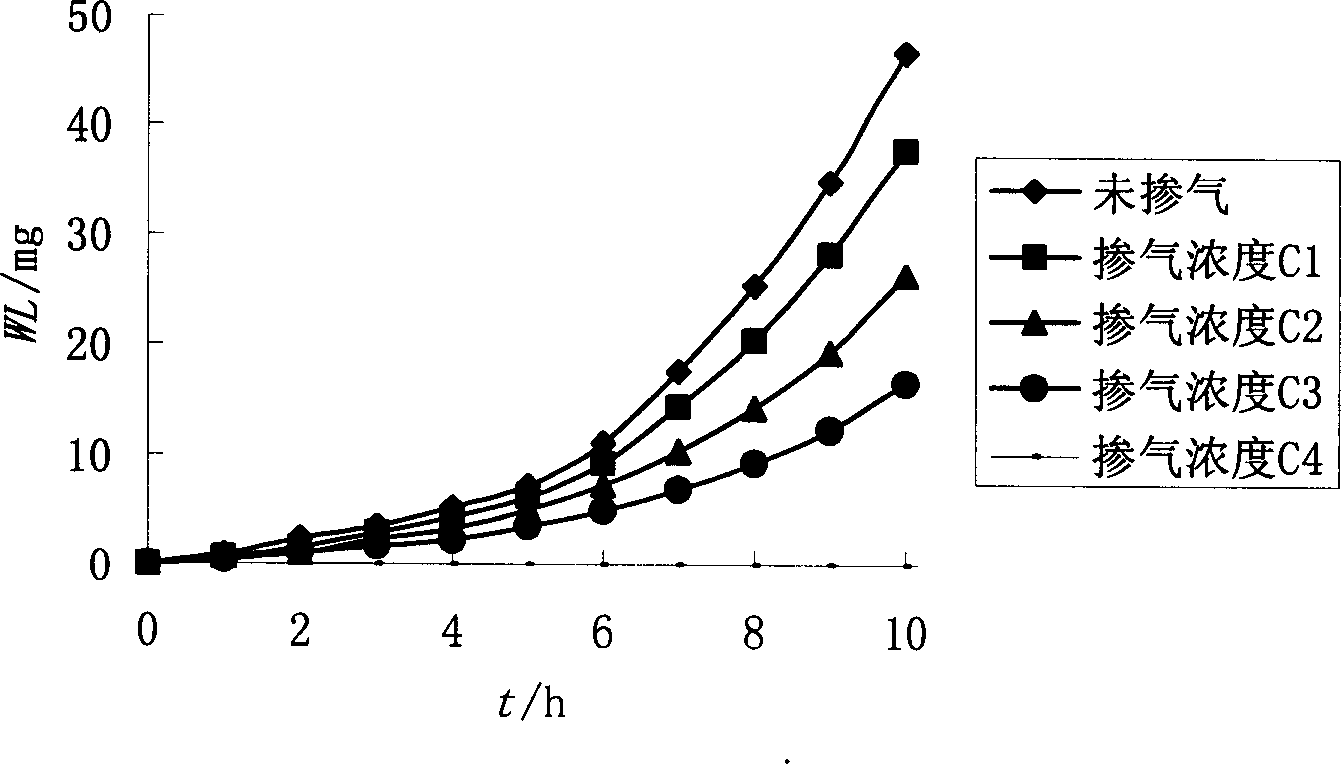

[0038] The vibration frequency of the magnetostrictive instrument used in this embodiment is 19.3kHz, the amplitude is 50 μm, and the power is 1000W. The test piece is 0Cr13Ni9Ti stainless steel, and the test solution used is water, such as figure 1Shown, add water in the container 14 that test solution is housed in magnetostrictive instrument of the present invention, 0Cr13Ni9Ti stainless steel test piece 13 is contained in magnetostrictive instrument horn 12 lower ends, adjust test piece 13 height, make test piece 13 Just submerged in water for 3mm, start the magnetostrictive instrument to make the test piece 13 axially vibrate at high frequency in the water, since the vibration frequency of the magnetostrictive instrument is 19.3kHz, the amplitude is 50μm, and the power is 1000W, so the test piece 13 vi...

Embodiment 2

[0040] The test equipment is the same as in Example 1, and the material of the test piece is CrMnN stainless steel that has undergone solid-liquid treatment at 1000°C + tempering heat treatment at 600°C. Test method and test condition are exactly the same as embodiment one.

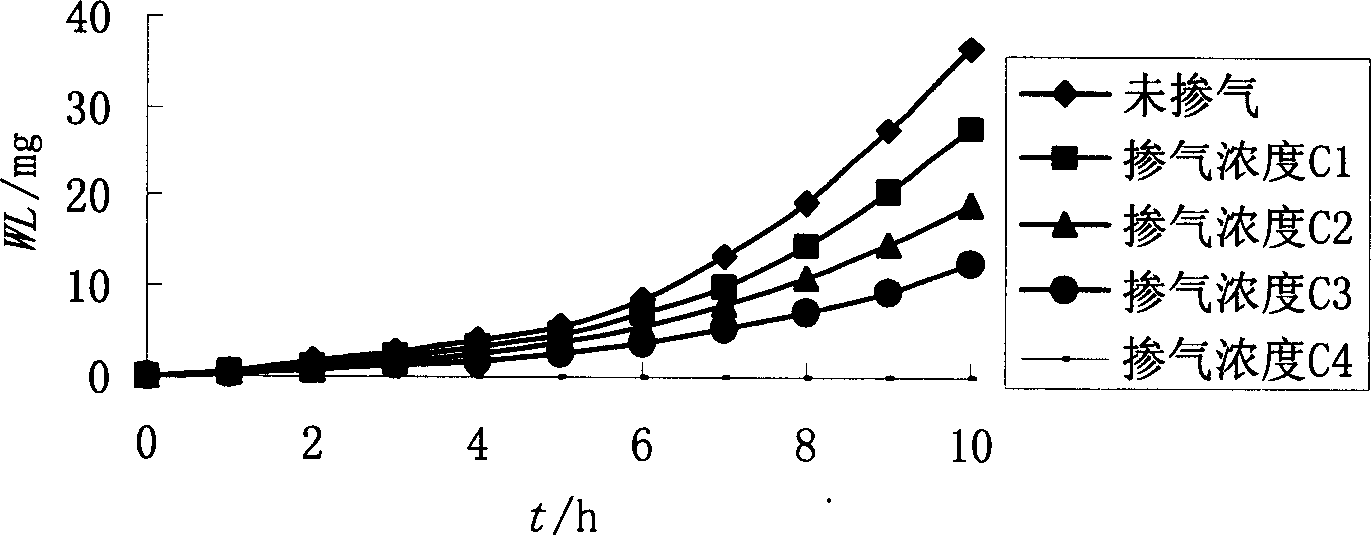

[0041] According to the measured data of the test, the relationship curve between the mass loss of the test piece and the gas concentration and test time is made, see image 3 . The aeration concentration value C12 It can be obtained by interpolating enough experiments between C3 and C4.

Embodiment 3

[0043] The orifice plate 25 in Embodiment 1 and 2 is disassembled, and air is mixed by microporous air distribution method. The aeration device adopts the zy type variable microporous aerator of Hangzhou Lanke Environmental Protection Technology Co., Ltd., the diameter of the synthetic rubber diaphragm is Φ200mm, the size of the aerator is Φ215mm, and the air bubbles generated by the aerator are directly ≤3mm. Other test conditions, test pieces and method steps are the same as in Embodiment 1. The relationship curve between air concentration and test time is as follows: Figure 4 shown.

[0044] Due to the different system configurations, under the same air pressure, the aeration concentration is not equal to that in Examples 1 and 2. When the readings of the barometer 23 are P1=0.001MPa, P2=0.0015, P3=0.002MPa, and P4=0.034MPa, the corresponding aeration concentration values are C5, C6, C7, and C8.

[0045] The critical non-corrosion gas concentration value CX under this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com