Method and tower for batching the aggregates in a plant for producing bituminous concretes and related production plant

A technology of asphalt concrete and coagulation, which is applied in the direction of roads, road repairs, roads, etc., and can solve problems such as the impossibility of standardization of waiting silos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

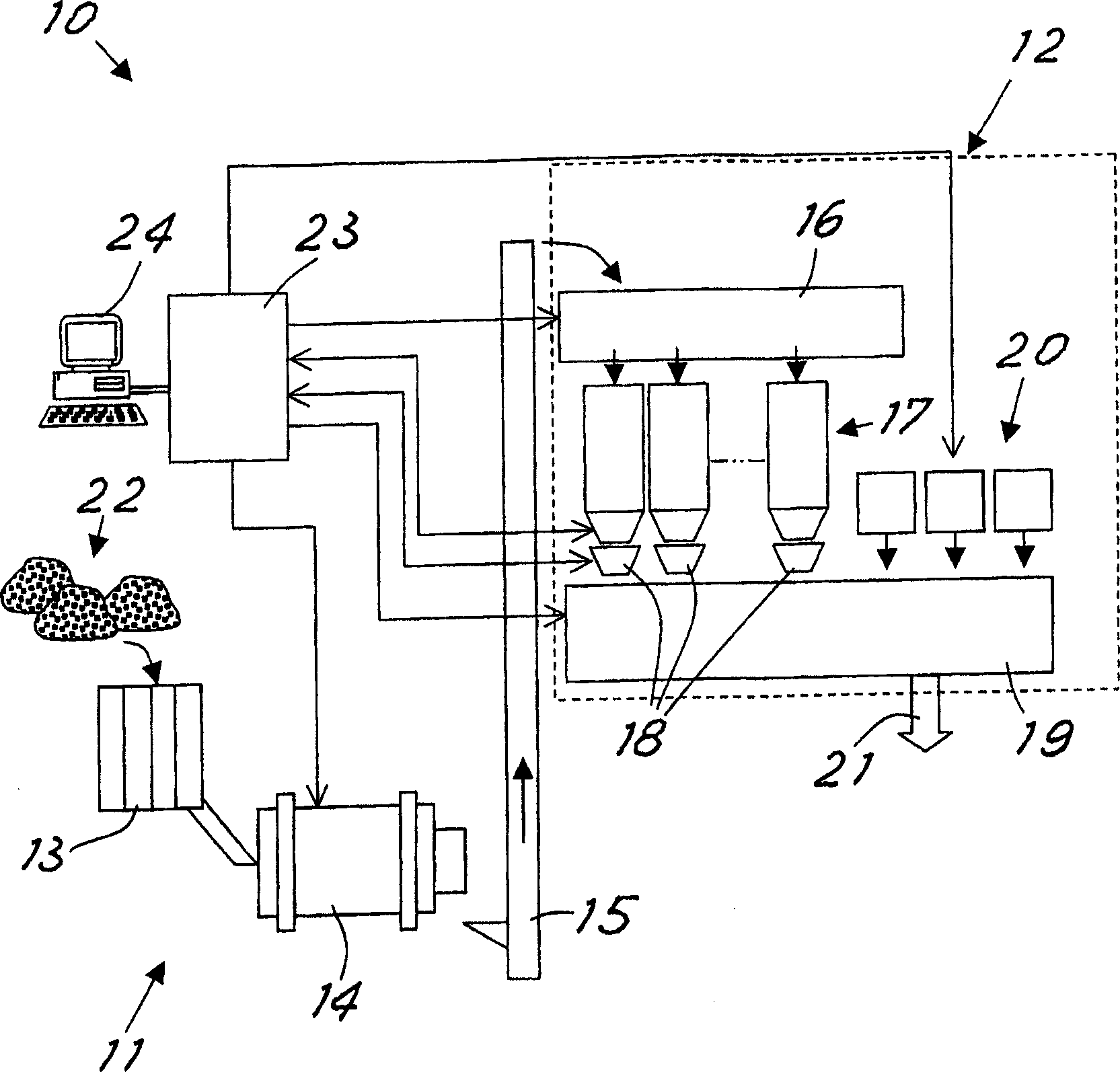

[0038] See attached picture, figure 1 A schematic diagram of an apparatus, generally indicated at 10, for the production of asphalt concrete is shown in . The plant 10 includes a zone 11 for preparing the aggregate and a zone or tower 12 for measuring or metering and mixing the formulation ingredients.

[0039] Zone 11 includes, for example, a feed device 13 which receives aggregates of different particle sizes (obtained by buckets from the stockpile 22 ) and feeds them into a known dryer 14 . The hot aggregate coming out of the dryer is lifted by a known elevator 15 , such as a bucket elevator, to the top of the mixing tower in zone 12 .

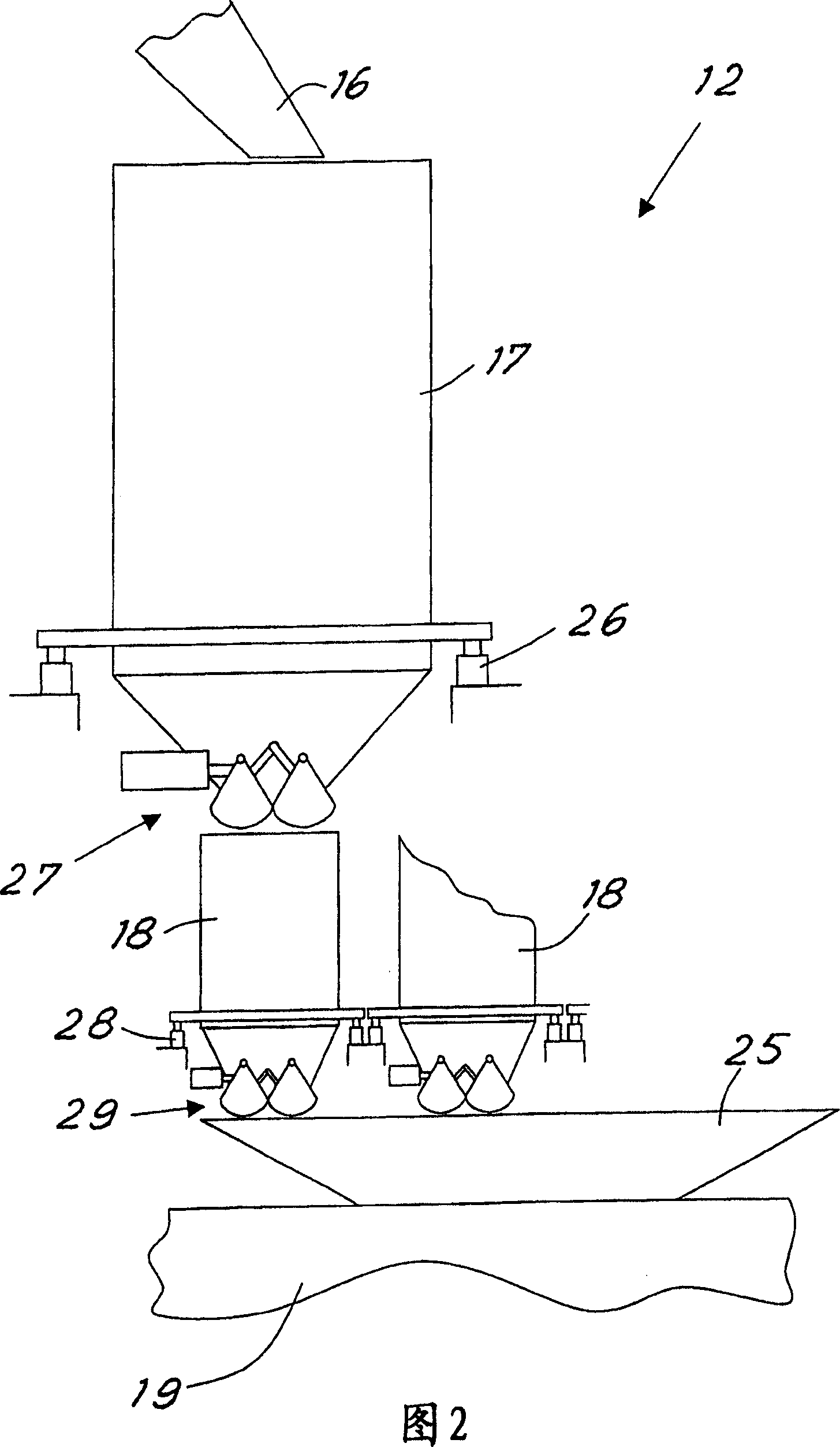

[0040] The different aggregates are sorted (by known sorting devices 16 ) into a plurality of storage or waiting silos 17 . As is known to those skilled in the art, depending on the mode of aggregate supply from zone 11, the sorting device may be of any known type. For example, if the aggregates had been selected in zone 11 and conveyed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com