Single-driven input shaft draft-adjustable three-roll mill

A three-high rolling mill and reduction technology, which is applied in metal rolling stands, metal rolling mill stands, metal rolling and other directions, can solve the problems of low transmission accuracy and small reduction compensation, and achieve high dimensional accuracy of products. , the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

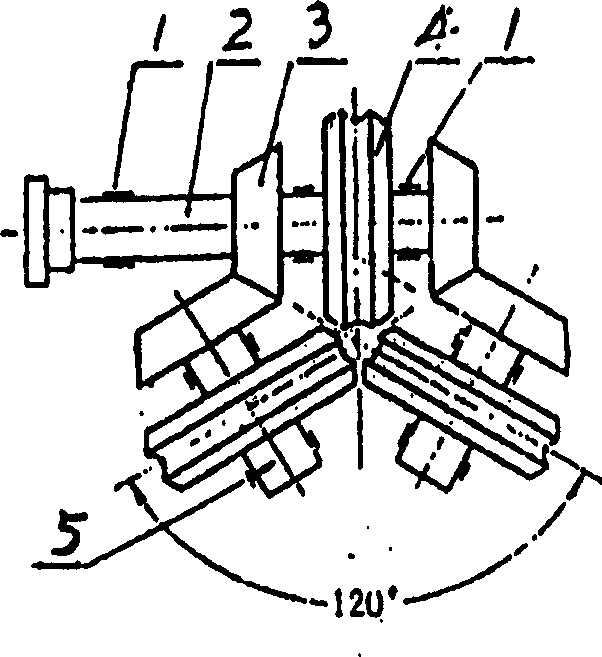

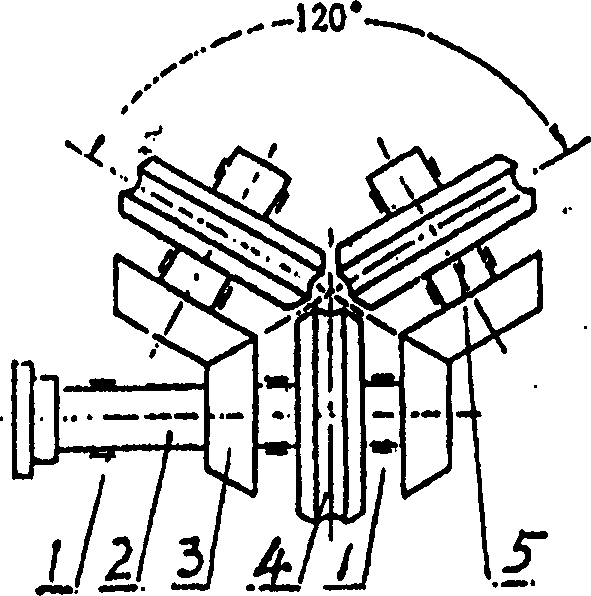

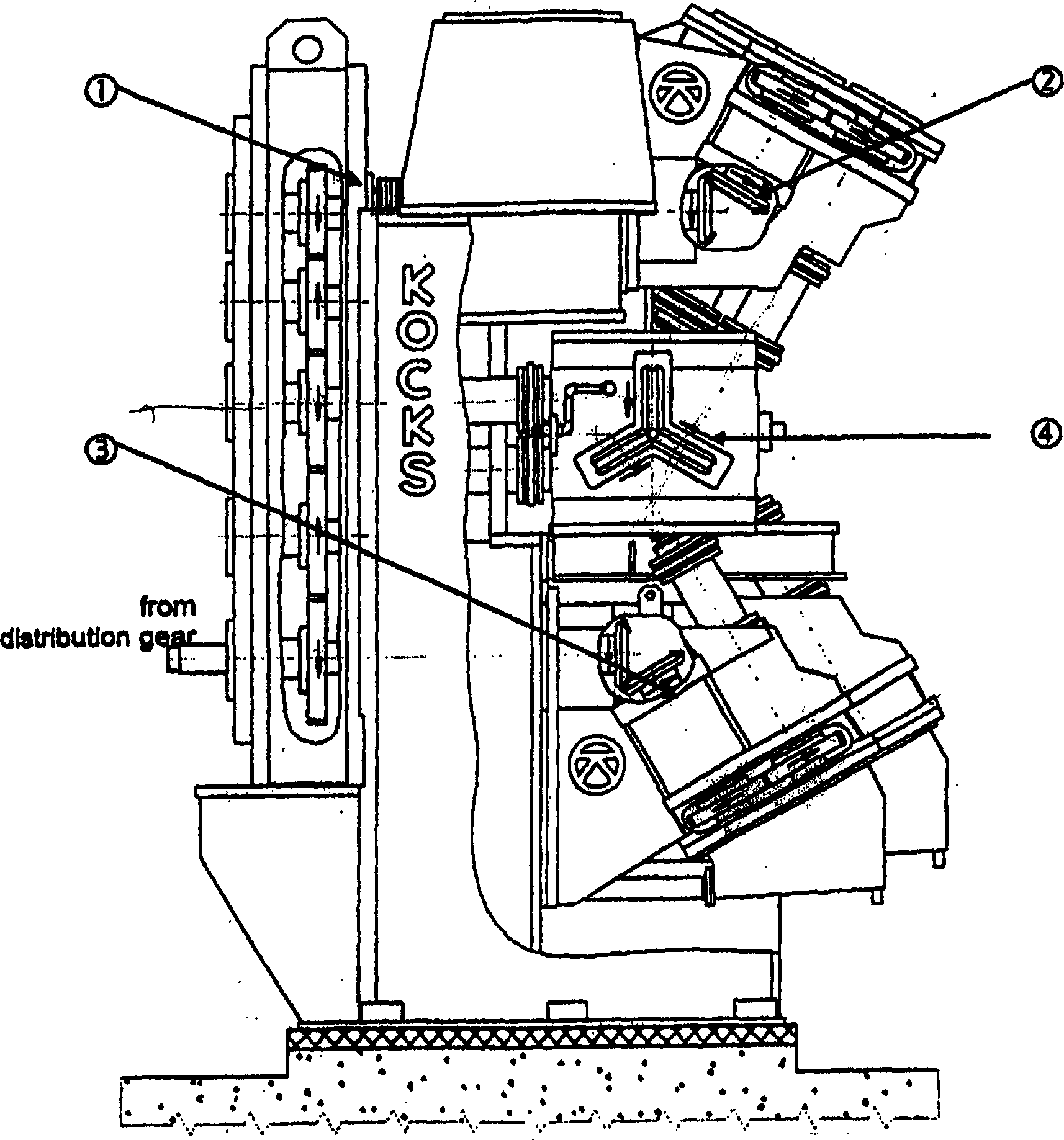

[0017] Figure 5 It is a schematic diagram of the mechanism of Embodiment 1 of a three-roll rolling mill with adjustable reduction of a single transmission input shaft of the present invention, as shown in Figure 5 As shown, the main transmission shaft 1 and two driven shafts 11 are respectively installed at 120° in the frame 8, a bevel gear 9 is fixedly installed on each of the three shafts, two bearings 10, and two bearings 12 are installed. , two bearings 14, roll rings 17 and other components, the roll system, the pressing device, etc., are characterized in that: the bevel gears on the three transmission shafts arranged at 120° are fixedly connected with the three shafts and are connected between the rolling mill transmission and The center line is always the same when pressing and adjusting, and an external gear 7 is fixedly installed on the main transmission shaft 1 and the two driven shafts 11, and the roller sleeve 6 with the internal gear and the roller sleeve 6 are ...

Embodiment 2

[0019] Embodiment 2: The structural feature of this embodiment is that the reduction synchronous adjustment mechanism of the three rollers is realized by the first stage gear transmission and the second stage worm gear (with eccentric sleeve) worm drive.

Embodiment 3

[0020] Embodiment 3: The structural feature of this embodiment is that the synchronous adjustment mechanism for the reduction of the three rollers is realized by the first-stage chain drive and the second-stage worm gear (with eccentric sleeve) worm drive.

[0021] The roll system adjustment mechanism of the three-roll rolling mill with adjustable reduction of the single transmission input shaft can be used for rolling ferrous metals and can also be used for rolling non-ferrous metals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com