Valve hole ream-extrude working method

A processing method and reaming technology, applied in metal processing equipment, reamers, manufacturing tools, etc., can solve the problems of poor rigidity of reamers, non-interchangeability, uneven force on teeth, shorten production cycle, and ensure consistency performance, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

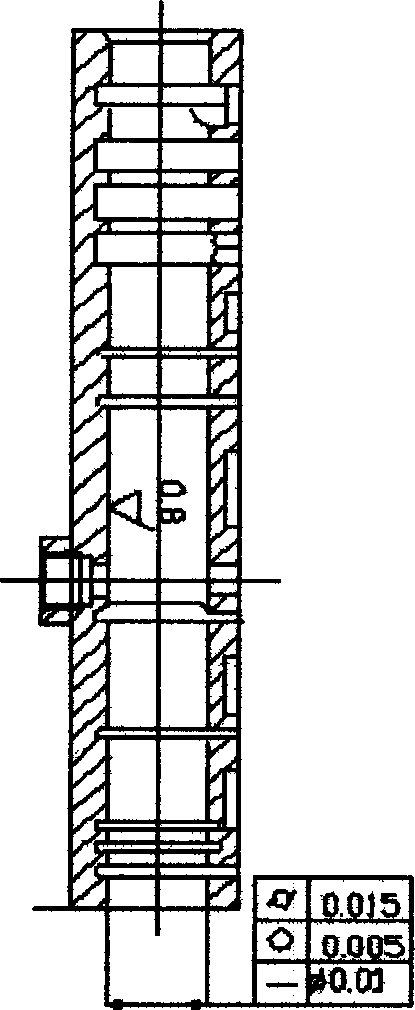

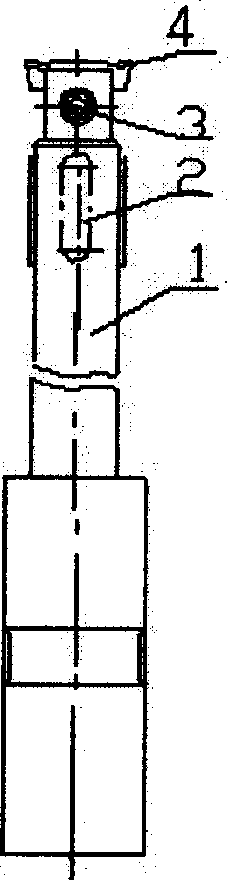

[0020] Embodiments of the invention: in combination figure 1 processing parts, figure 2 , image 3 tool description.

[0021] The processed deep valve hole such as figure 1 As shown, after processing, the accuracy is: diameter change: 0.005, surface roughness Ra0.8, straightness: the hole can pass through the inspection rod with a diameter direction and hole gap of 0.005-0.01, roundness: roundness Instrument inspection, less than 0.005. Its implementation method is as follows:

[0022] Selection method process: reaming - semi-finish boring - reaming;

[0023] Select cutting speed Vc=4~7m / min, feed rate f=0.07~0.15mm / r, cutting depth ap=0.08~0.3mm, extrusion amount 0.007~0.03mm.

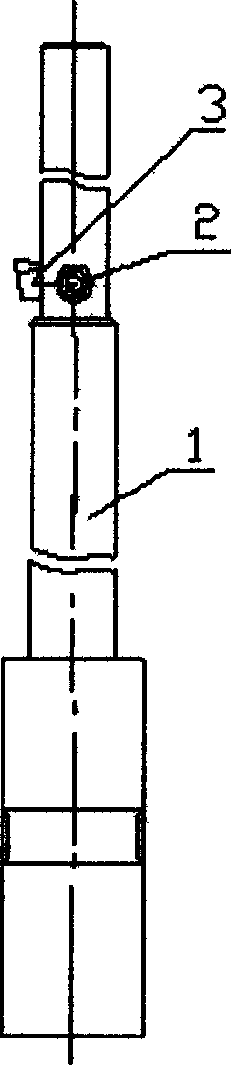

[0024] First, carry out reaming, using a reaming knife ( figure 2 ), the reaming cutter includes a cutter body (1), a clamping screw (2) and a blade (3); when in use, both ends are supported, which increases the rigidity of the cutter body and increases the stability of the cutter during cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com