Hot-press printing method

一种热压印、压模的技术,应用在热压印领域,能够解决成本高、操作复杂等问题,达到成本低、操作简单、利于高精度转移的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing.

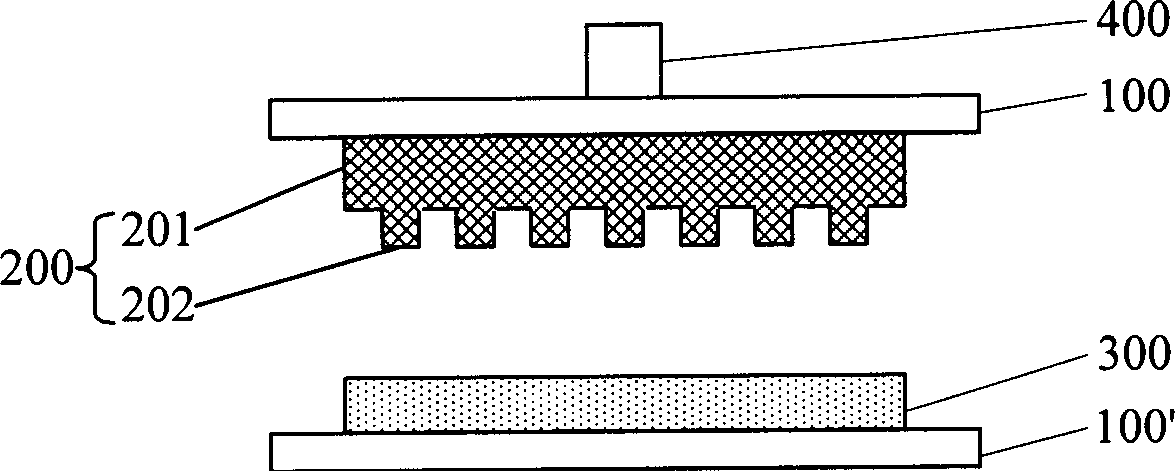

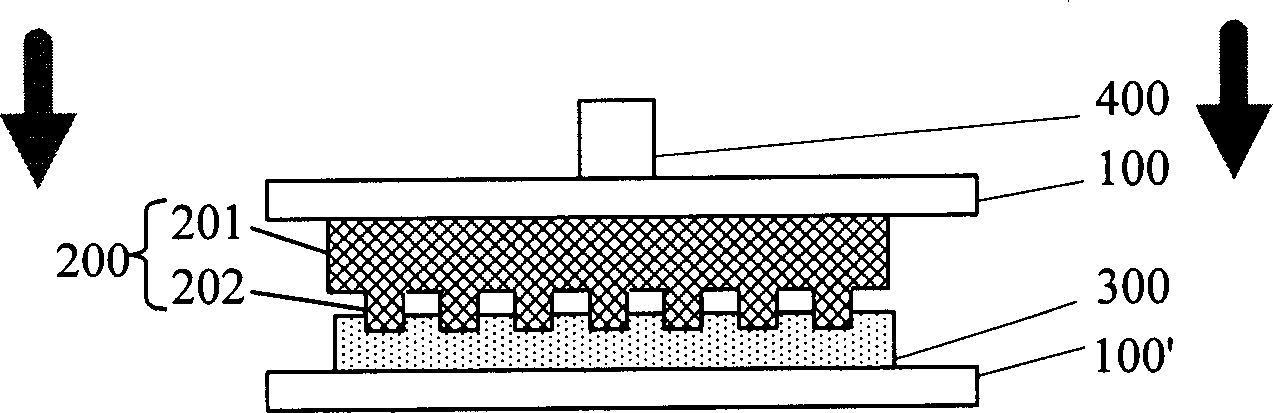

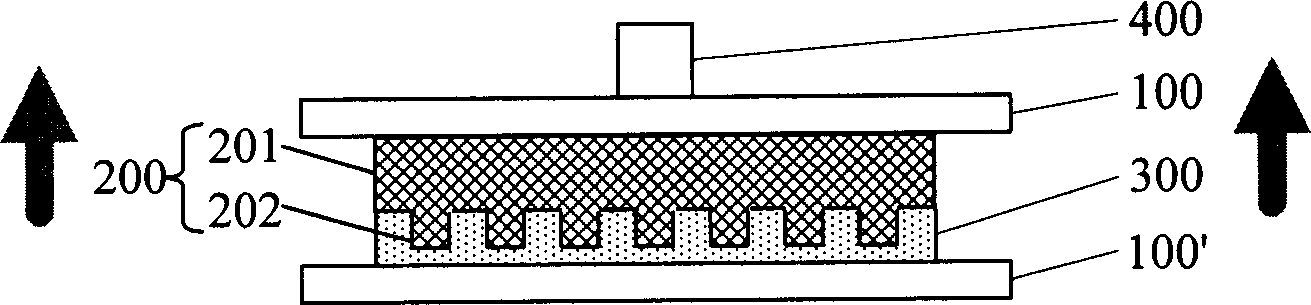

[0027] see Figure 2(a)~2(d) , the thermal embossing method provided by the present invention, it comprises the following steps:

[0028] As shown in Figure 2 (a), a substrate 30 is provided, which is a polymer material, and at its glass transition temperature (hereinafter referred to as T g Indicates that) has better fluidity; for example, polymethyl methacrylate (PMMA), its glass transition temperature T g About 105°C;

[0029] A stamper 20 is provided, which is composed of a stamper body 21 , a predetermined pattern of convex structures 22 formed on the stamper body 21 , and concave structures (not shown) between adjacent convex structures. The die material is harder than the base material, and has the characteristics of high Knoop hardness (Knoop micro-indentation hardness), high compressive strength, high tensile strength, high thermal conductivity, low th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com