Exhaust-system support for fixing the exhaust system of a motor vehicle

A motor vehicle and exhaust system technology, applied in the direction of exhaust device, power device, and power device gas intake, etc., can solve the problem that the rubber suspension will not be provided, and achieve the effect of compact layout and reasonable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

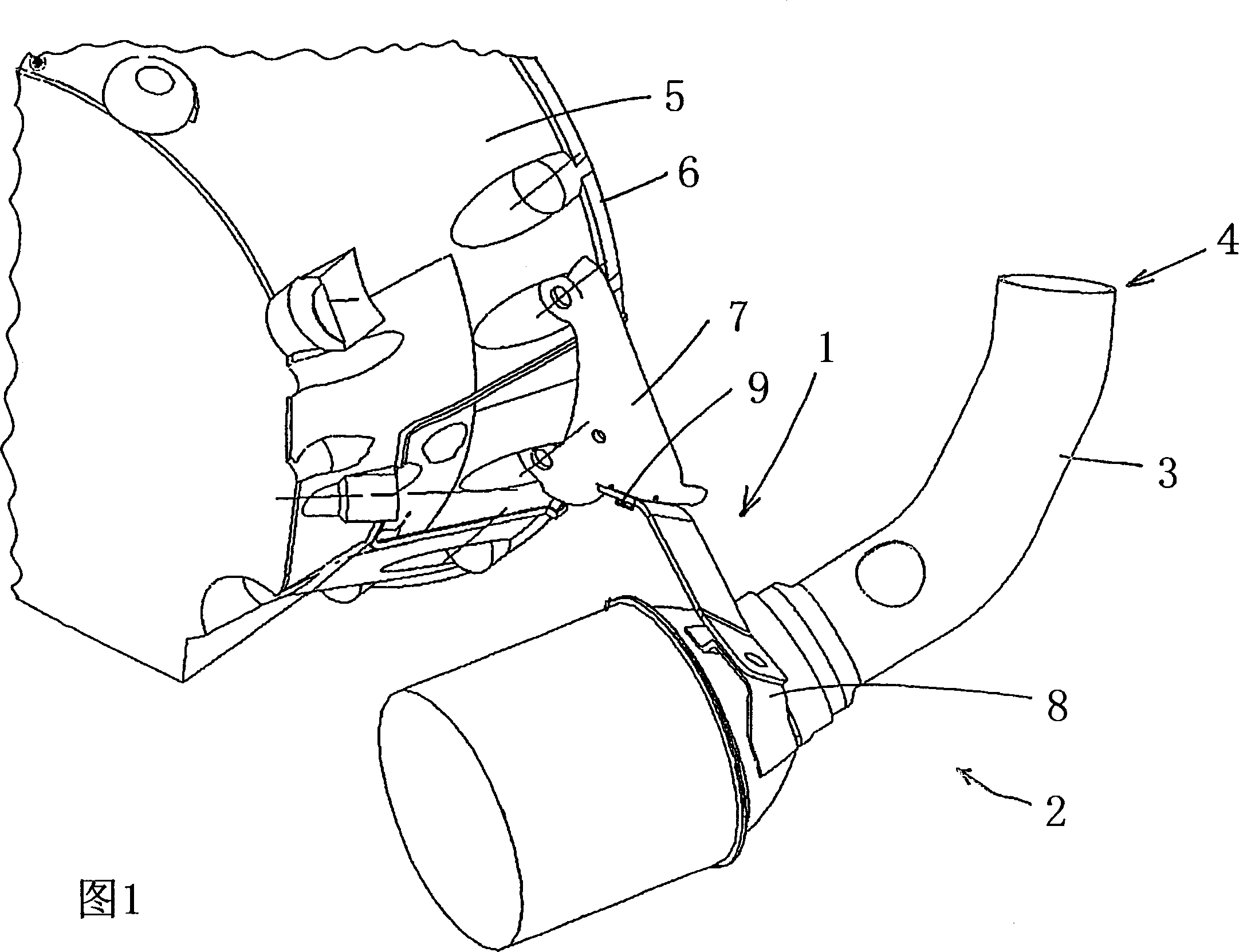

[0032] Referring first to FIG. 1 , there is shown a general representation of a bracket designed and used in the exhaust system according to the present invention.

[0033] An internal combustion engine has an exhaust system 2 to which exhaust gas is supplied from an exhaust manifold (not shown) via an exhaust manifold 4 adapted to the upstream duct 3, said exhaust system being The support member 1 in the form of an inventive plate holder is fixed to the gearbox housing 5 . The gearbox housing 5 is connected with the engine body through the engine body coupling device 6 . On the exhaust system side, the support member 1 is fixed to the exhaust system, ie to the funnel-shaped inlet of the catalytic converter, by means of a bracket 8 . The supporting member 1 and the bracket 8 are connected by welding. On the gearbox side, the support member 1 according to the invention is fixed to said gearbox housing 5 by means of brackets 7 . The support member 1 is fixed to the bracket 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com