Evaporator and its manufacturing method

A technology for evaporator and refrigerant circulation, which is applied in the field of evaporator and its manufacturing, can solve the problems that need to be improved, and achieve the effect of suppressing odor emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-4

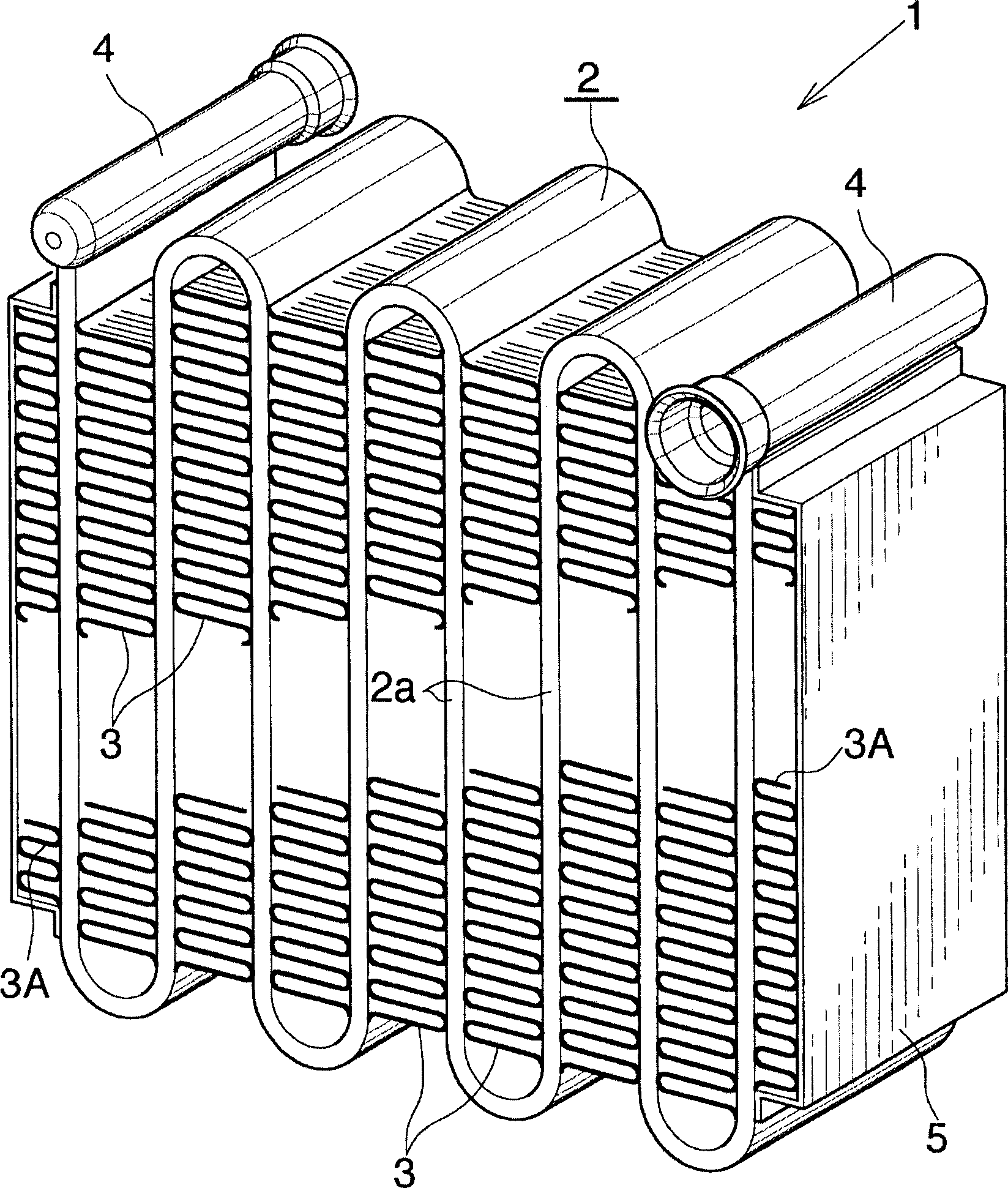

[0077] A flux suspension comprising flux (FL-7, product of Morita Kagaku Co., Ltd.) suspended in water containing a binder (SURFBEST 1100, product of NIPPON PAINT Co., Ltd.) was prepared. A Z-shaped flat tube made of aluminum extruded profile, a corrugated fin made of aluminum brazing sheet with layers of brazing material on both sides, aluminum side plates and two kinds of aluminum headers were prepared.

[0078] Various amounts (calculated from the flux itself) of the flux suspension were applied by brushing to the entire outer surface of the zigzag flat tube. Then, corrugated fins are arranged between each pair of adjacent straight pipe parts of each zigzag pipe, two corrugated fins are arranged outside each straight pipe part at both ends of the pipe, and two side plates are arranged on the The exterior of the corrugated fins at each end, the two headers are connected to the ends of the zigzag tube and the resulting assembly is secured with suitable clamps.

[0079] Subse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com