Reactor core loading method of pressurized water reactor nuclear power station reactor

A pressurized water reactor nuclear power plant and reactor technology, applied in the field of nuclear power plant nuclear reactor, can solve the problems of large neutron leakage, poor fuel utilization economy, short cycle length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

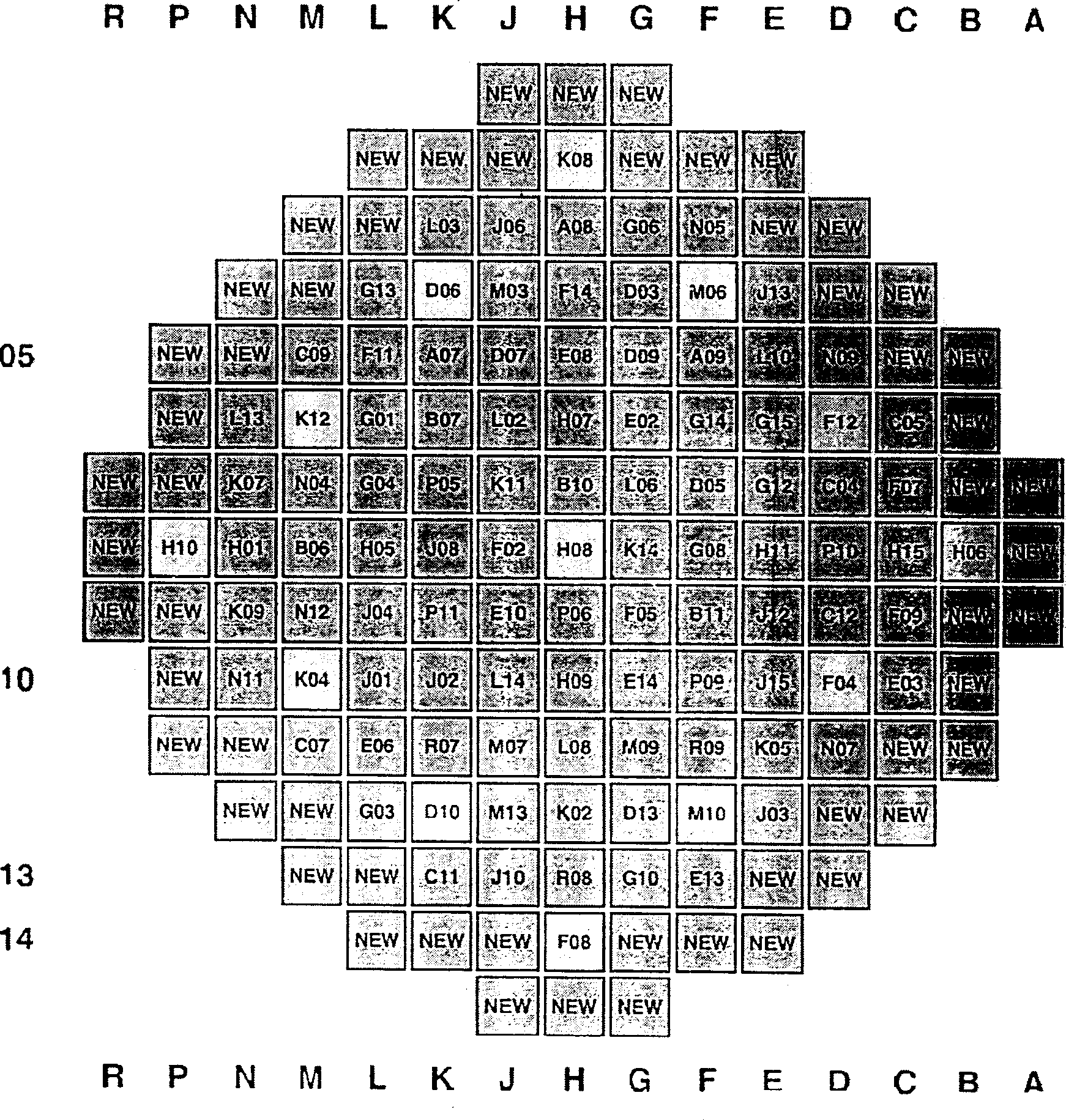

[0017] The design of the present invention is to stack components that need to be updated in the inner circle of the core, and the outermost periphery is loaded with components that have burned up.

[0018] During the loading process of the entire core, new components can be loaded in the inner ring of the burned-up components loaded on the periphery, and then in the inner ring, the burnt-up components and new components can be used in combination according to the degree of burn-up, and the burn-up Components with different consumption depths are arranged crosswise.

[0019] The assembly loading and arrangement mode of the core of the present invention takes 1 / 4 of the core as a combination, and the whole core is composed of four above-mentioned combinations of the cores, which are arranged symmetrically in 1 / 4.

[0020] In order to make the components burn deeper and generate more energy, Gd2O3 dispersible combustible poisons can be added to the new components.

[0021] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com