Semiconductor film inner packing layer enlarging optical fiber and its premade rod manufacturing method

An inner cladding and semiconductor technology, applied in manufacturing tools, glass manufacturing equipment, etc., can solve problems such as material decomposition, and achieve the effects of less material decomposition, high amplification gain, and stable semiconductor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

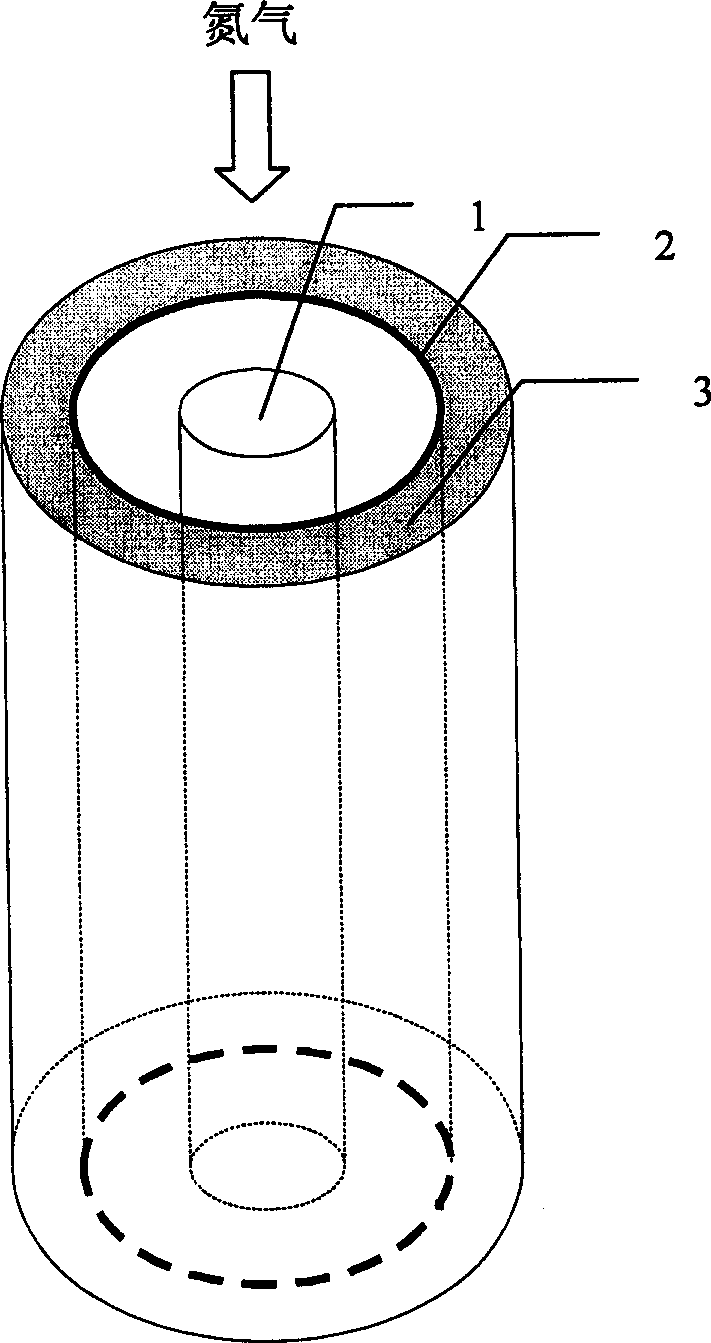

[0017] A preferred embodiment of the present invention is: the semiconductor thin film inner cladding amplifying optical fiber is made up of a core rod, an inner cladding and an outer cladding, the inner cladding is sandwiched between the core rod and the outer cladding, and the core rod is made of doped GeO 2 It is composed of quartz material, whose refractive index is higher than that of the pure quartz material of the outer cladding; the inner cladding is a thin film cladding, which is composed of an active semiconductor with a direct band gap material with amplifying function; and the outer cladding is composed of pure quartz.

[0018] The manufacturing method of the preform of the optical fiber, its manufacturing process and process steps are as follows:

[0019] a. Using improved chemical vapor deposition process to make core rod 1: fasten the quartz reaction tube on the improved chemical vapor deposition lathe, rotate at a speed of 50±5 rpm, and use high-purity O 2 Put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com