Exhaust structure for engine

一种引擎、排气管的技术,应用在排气装置、机器/发动机、机械设备等方向,能够解决不可能清除废气排出管路4冷凝水、引擎2损坏等问题,达到防止引擎损坏、提高寿命和可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

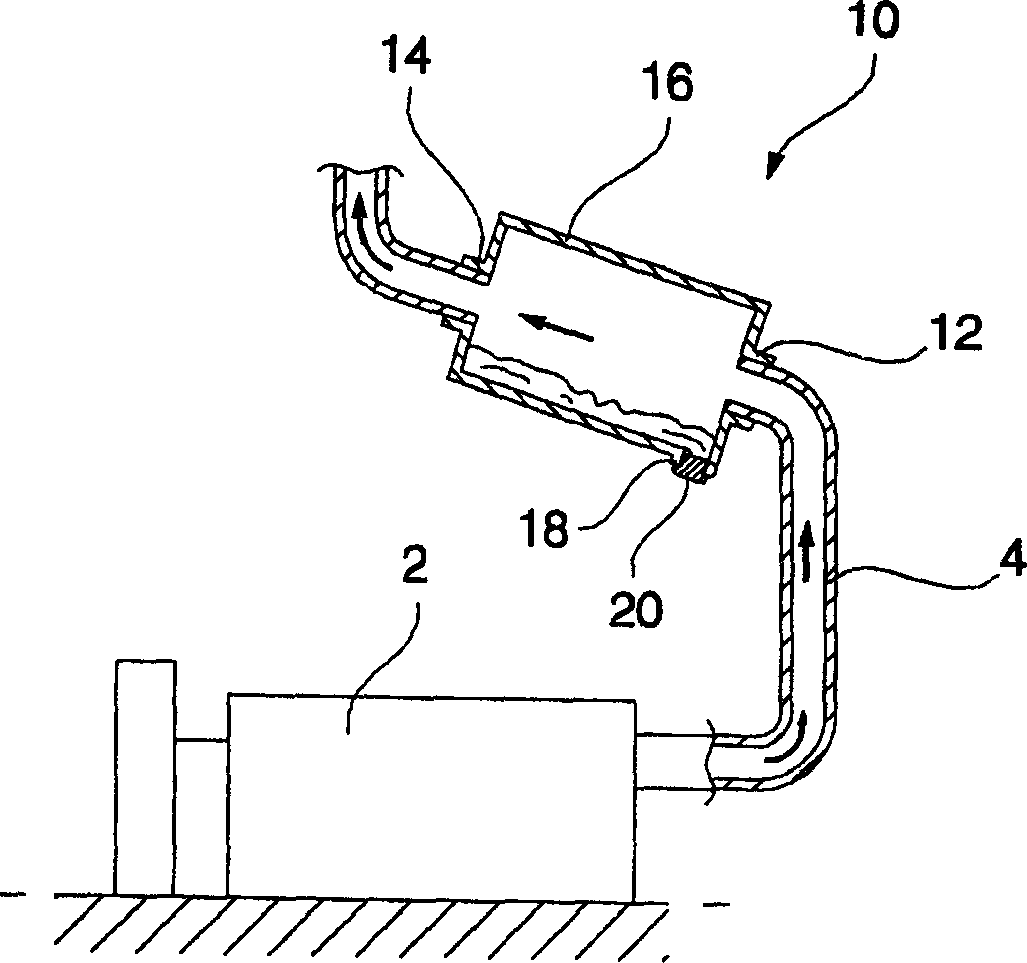

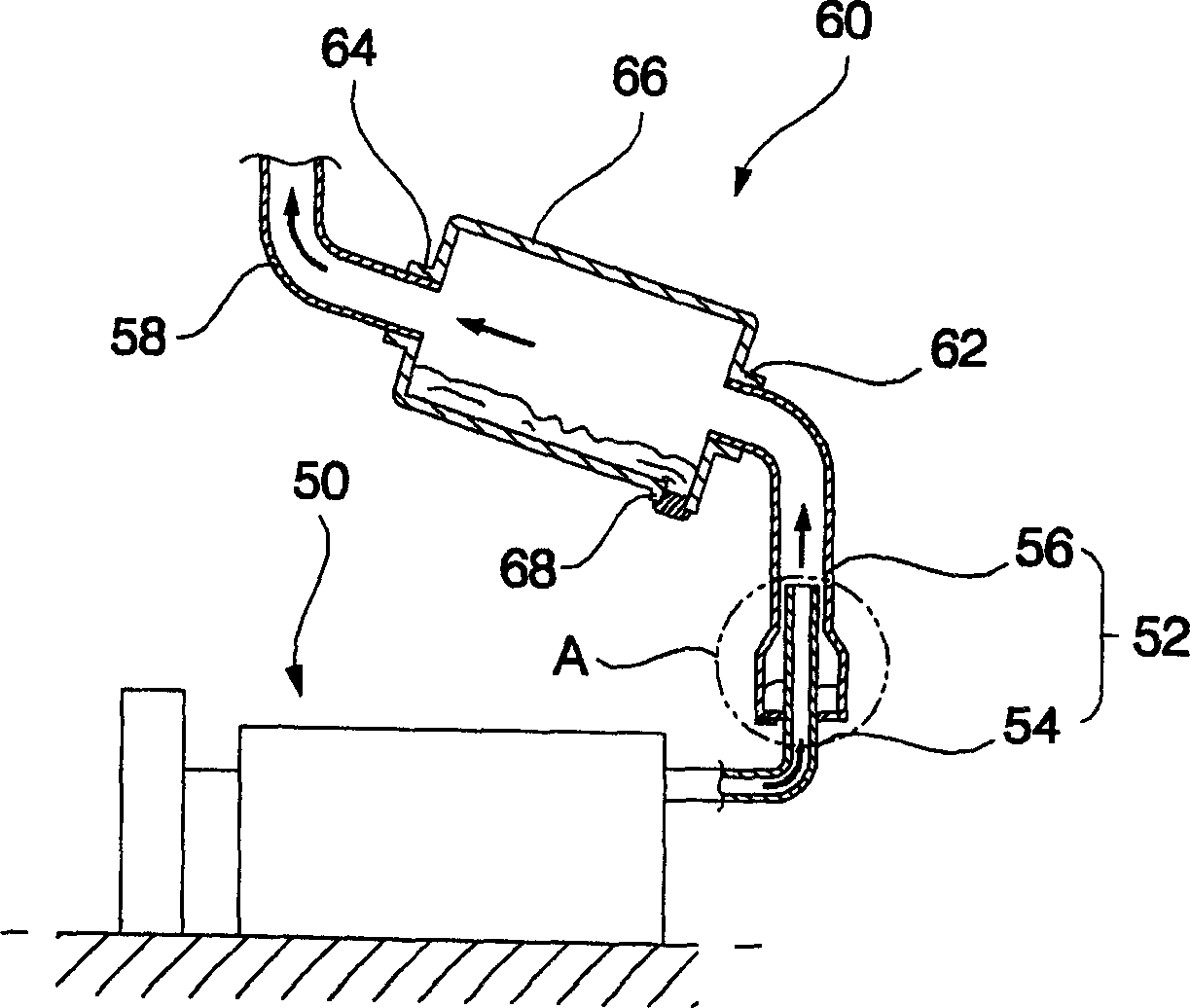

[0033] Exemplary embodiments of the combined heat and power system according to the present invention will be described below with reference to the accompanying drawings.

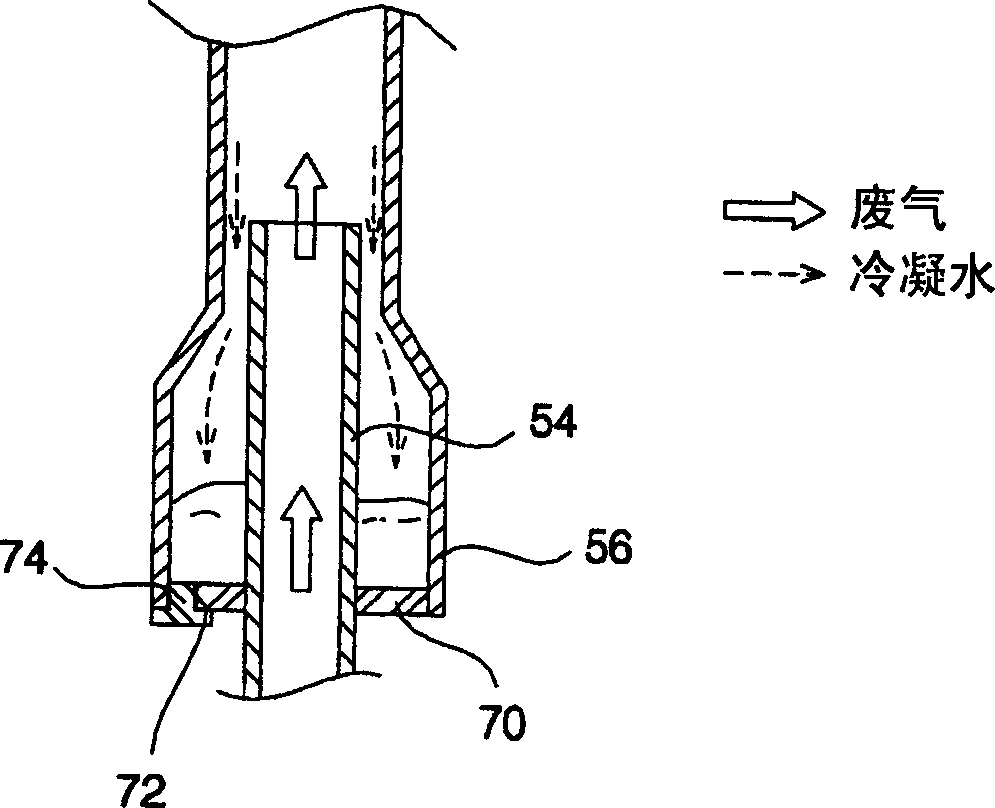

[0034] figure 2 is a schematic diagram showing an exhaust structure for an engine according to a first embodiment of the present invention. image 3 for corresponding to figure 2 An enlarged cross-sectional view of part A.

[0035] Such as figure 2 and image 3 As shown, the exhaust structure according to the first embodiment of the present invention is used to discharge the exhaust gas generated from the engine 50 to the outside, the exhaust structure includes an exhaust gas discharge pipe for discharging the exhaust gas generated from the engine 50 to the outside Road 52.

[0036] The exhaust gas discharge line 52 includes: a first exhaust pipe 54 connected to the engine 50 to guide exhaust gas discharged from the engine 50; and a second exhaust pipe 56 connected to the first exhaust pipe 54 to gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com