Plane luminous display of lowergrid structure and mfg. tech. thereof

A light-emitting display and lower gate technology, applied in the field of nanoscience, can solve the problems of relatively high requirements for insulating materials, inability to perform large-area production, and increase in the overall cost of devices, so as to reduce the probability of intercepting electrons, improve the success rate, and reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing and embodiment, but the present invention is not limited to these

[0044] Example.

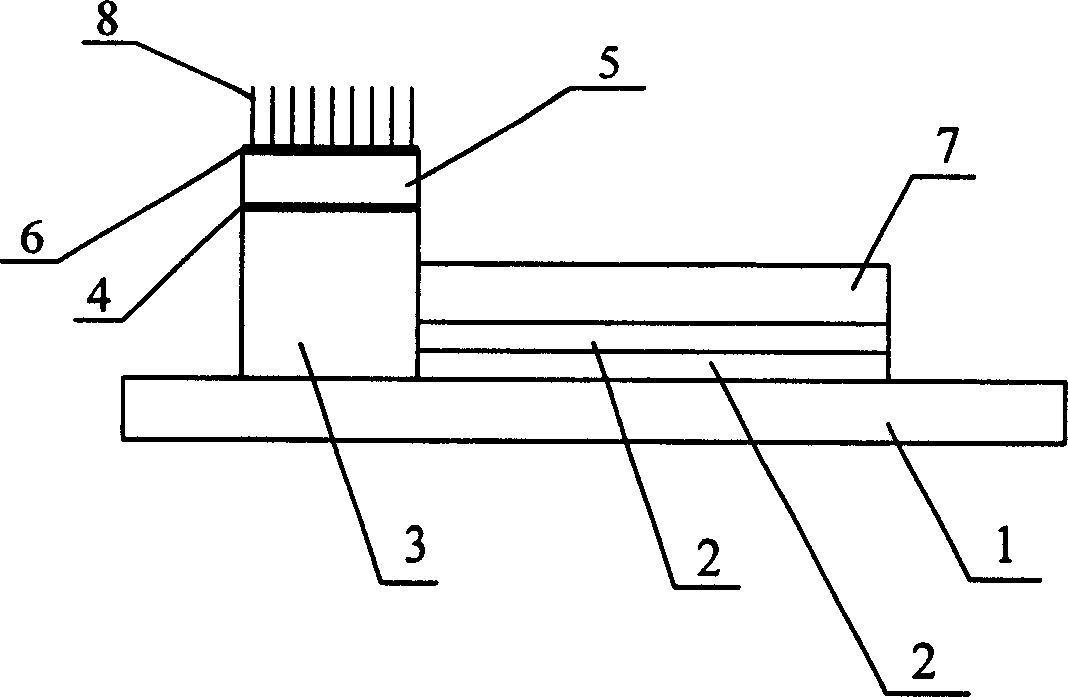

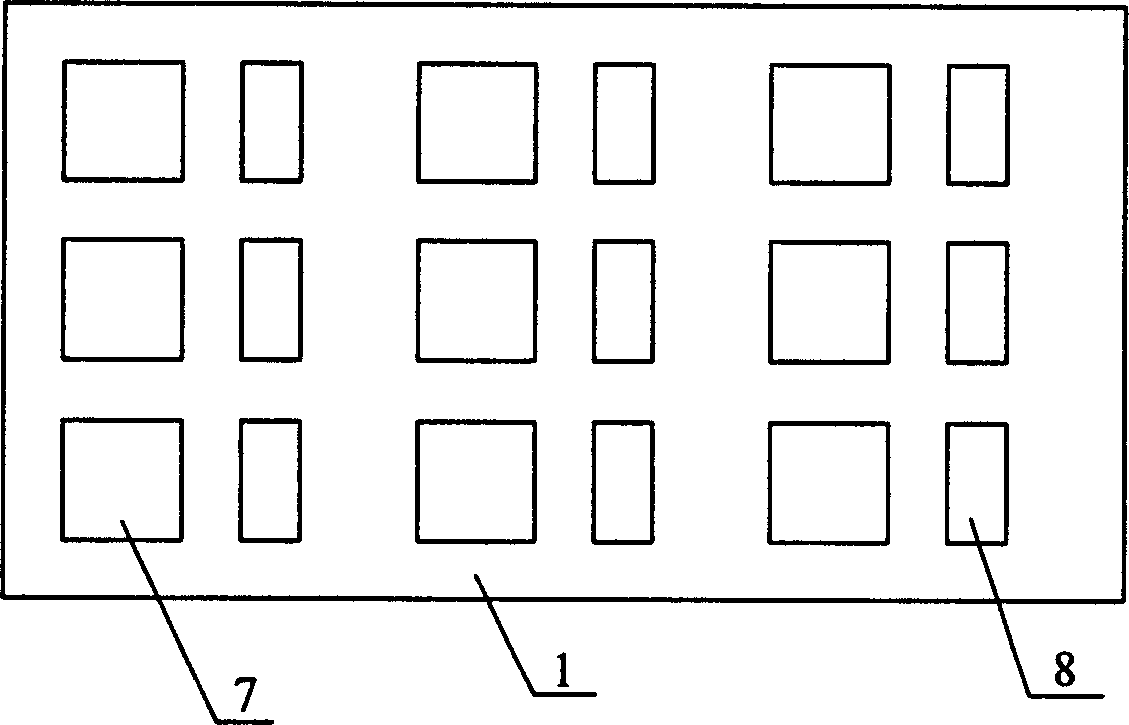

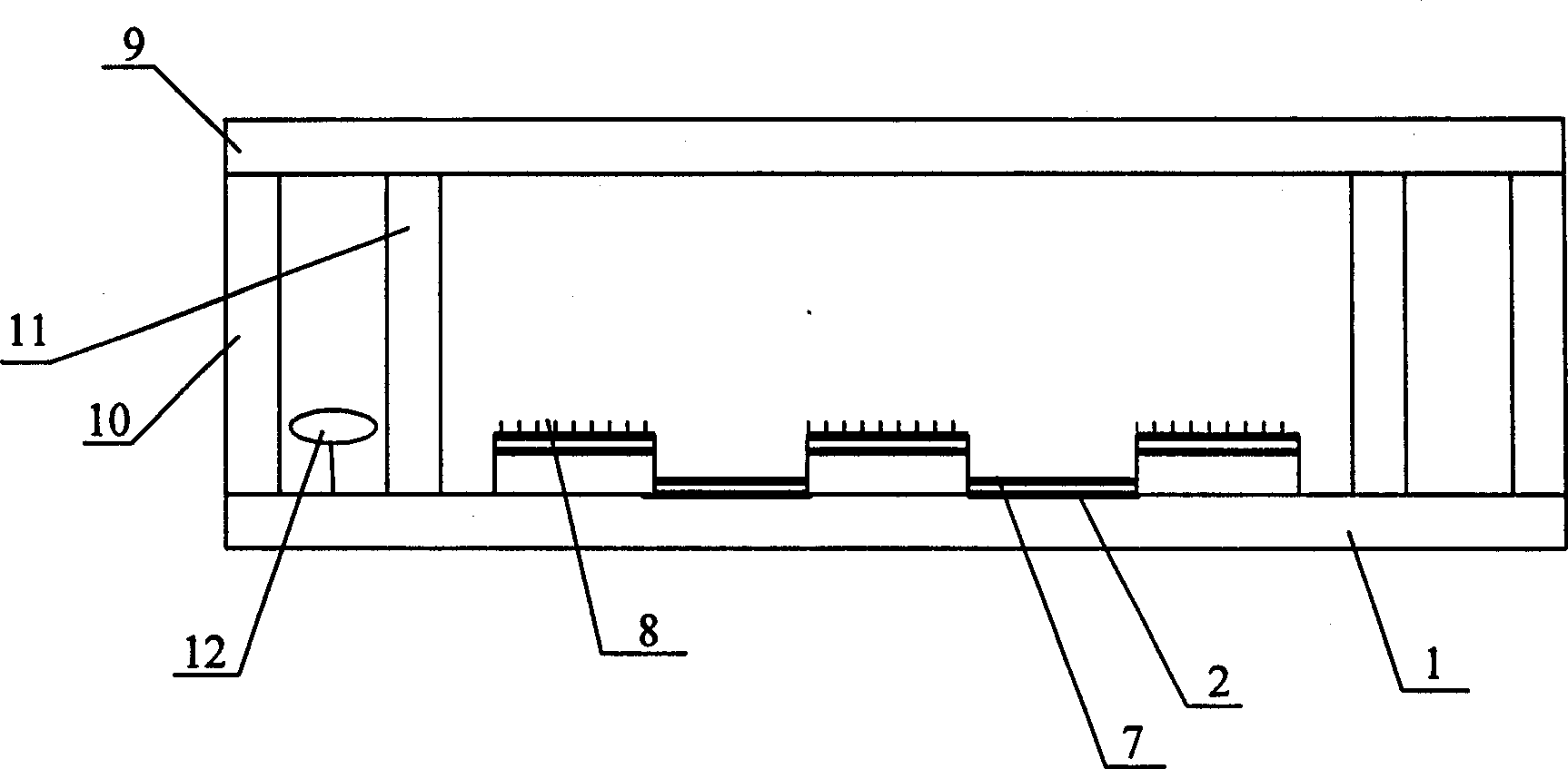

[0045] The present invention includes a sealed vacuum chamber composed of a front glass panel 9, a rear glass panel 1 and surrounding glass frames 10, a supporting wall structure 11 and an attached getter 12 element, and an insulating layer 3 is arranged on the rear glass panel. An anode pixel hole is reserved on the insulation enhancement layer 3, and in the anode pixel hole is an anode electrode layer 2 arranged on the rear glass panel 1, and a phosphor layer 7 is arranged on the anode electrode layer 2, and on the insulation enhancement layer 3 A control grid electrode layer 4 is provided, an insulating isolation layer 5 is arranged on the control grid electrode layer 4, a cathode electrode layer 6 is arranged on the insulation isolation layer 5, and a carbon nanotube cathode 8 is prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com