Knitting needle of interlock machine

A technology of cotton wool machine and knitting needles, which is applied in the field of knitting machinery, and can solve the problems of not meeting the needs of the market, insufficient adaptability, and inability to weave composite knitted fabrics with outer wool and inner cotton or outer linen inner cotton.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

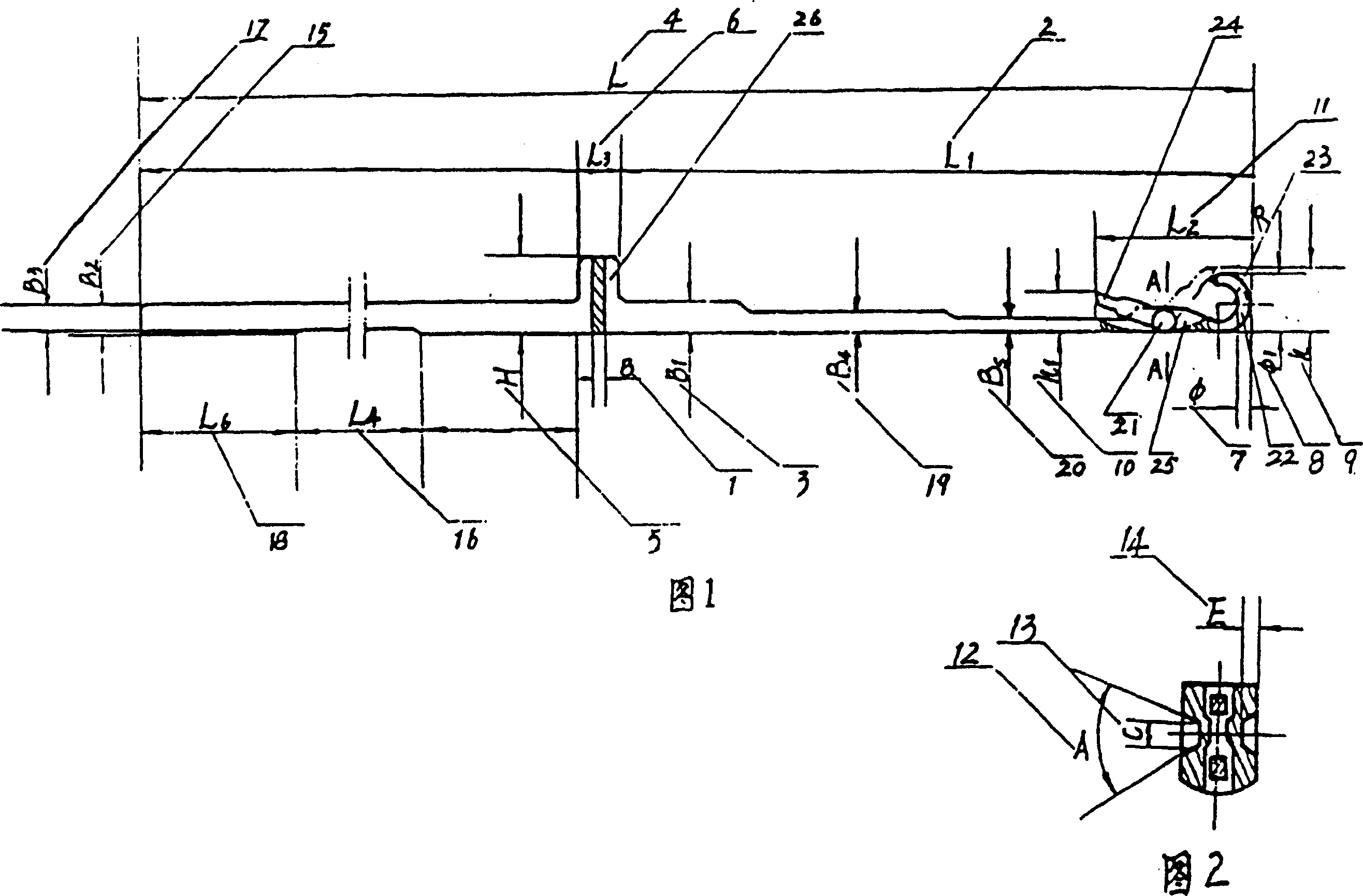

[0009] Cotton wool machine knitting needles are composed of needle body, needle latch and rivet (see Figure 1). The needle body includes needle body, stitches, and needle tail. There are needle hooks 22 and needle grooves 25 at the top. One end of the needle latch 24 is movably installed in the needle groove 25 with a rivet 21. There is a hole at the other end of the needle latch. When the needle latch covers the needle hook, the end of the needle hook is placed on the needle latch. In the hole, the needle diameter 7 is 0.7mm, the needle hook outer diameter 8 is 3mm, the needle hook inner radius 23 is 0.8mm, the upper tongue height 9 is 3.32mm, the lower tongue height 10 is 2.1mm, and the tongue tip distance of the needle is 11mm. 14.3mm, needle length 2 is 58.5mm, needle width 3 is 2.5mm, needle thickness 1 is 0.85mm, large curved bore width 19 is 1.9mm, small cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com