Water floating transporting method for super-large component

A super-large and component technology, which is applied in the direction of transportation and packaging, conveyors, and conveying bulk materials, can solve the problems of difficulty in ensuring the quality of super-large component manufacturing, limited facility conditions, and transportation vehicles and conditions that cannot be transported, etc., to achieve reduction Draft depth, easy on-site construction, and the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

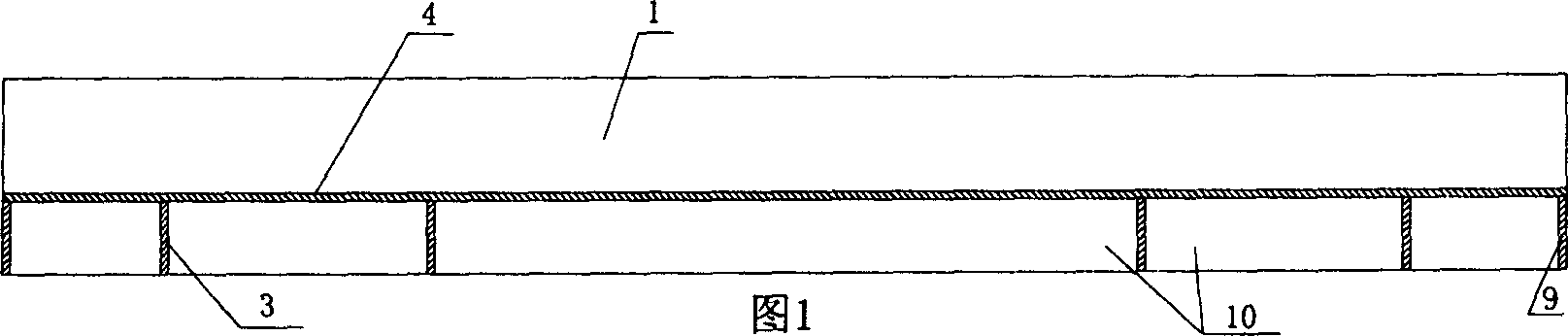

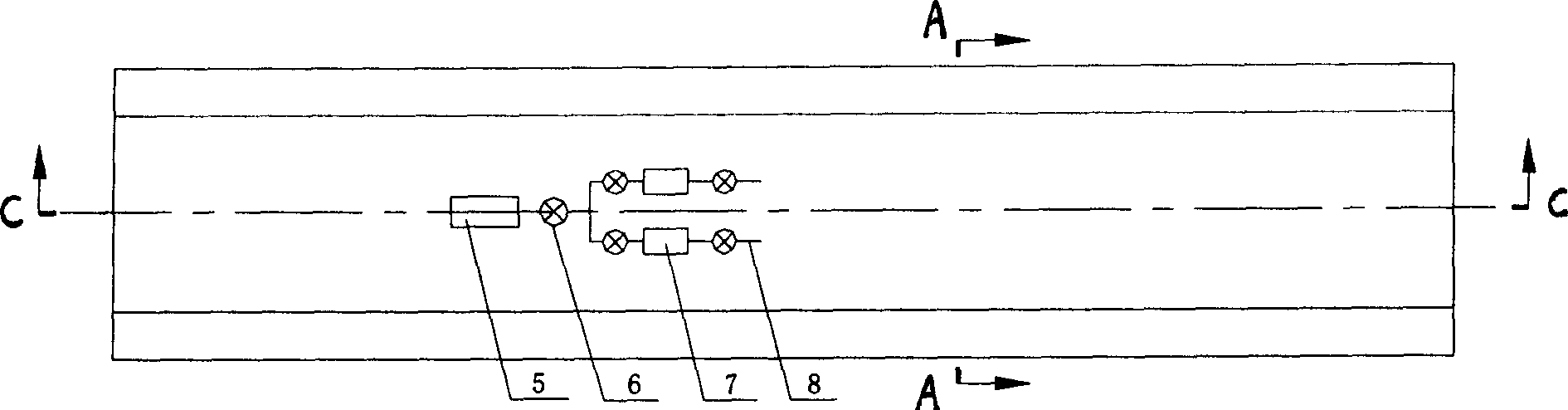

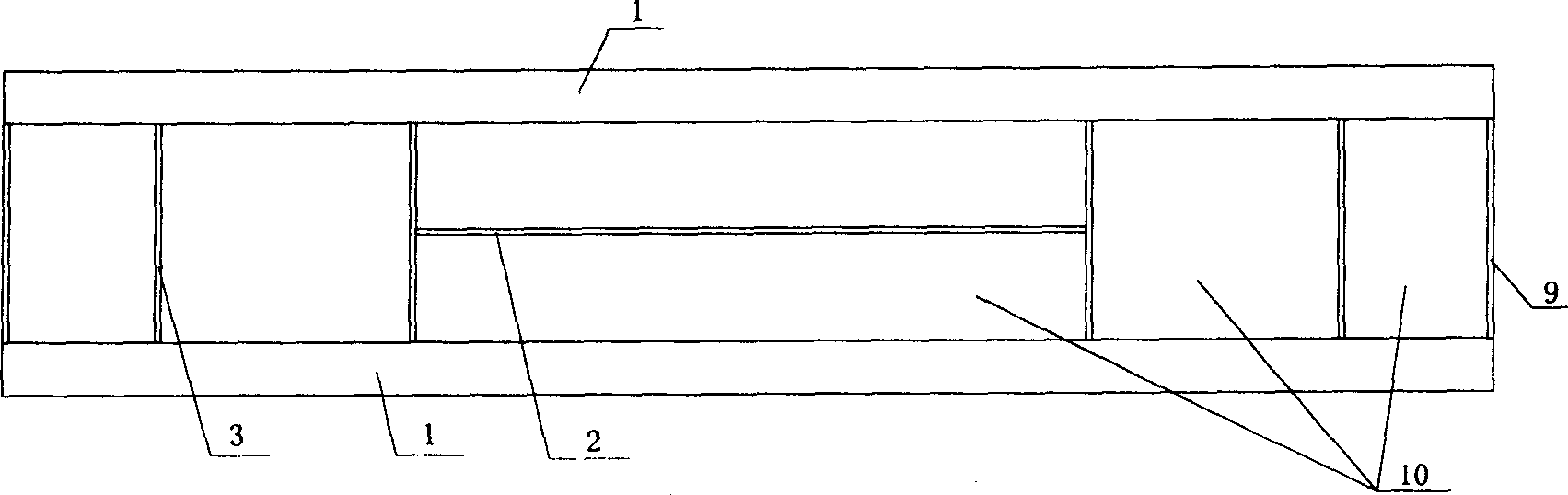

[0021] Further illustrate specific embodiments of the present invention below in conjunction with accompanying drawing, be used for the ship bearing box of dam, be an elongated steel box welded structural part, comprise the main stringer 1 of the box-shaped section that both sides are arranged, main Both ends of the stringer are closed to form a sealed cabin. The panel structure 4 is connected at the middle and lower part between the two main stringers. The panel structure is as long as the main stringer and runs through the entire ship. A crossbeam 3 is installed between the beams, and end beams 9 are provided at both ends, and the longitudinal beam 2 can be connected between the two crossbeams, thereby forming a A plurality of inflatable air chambers 10, each inflatable air chamber is isolated from each other, and only the lower side is open. In this embodiment, six inflatable air chambers are formed, and the middle is divided into two inflatable air chambers by longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com