Movable bogie with double swing links

A technology of moving trolleys and double swing bars, applied in vehicles with swing arms, manipulators, manufacturing tools, etc., can solve the problems of not being able to pick up multiple items at one time, complex structure, etc., and achieve good maintainability, scalability, volume, etc. The effect of small size and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

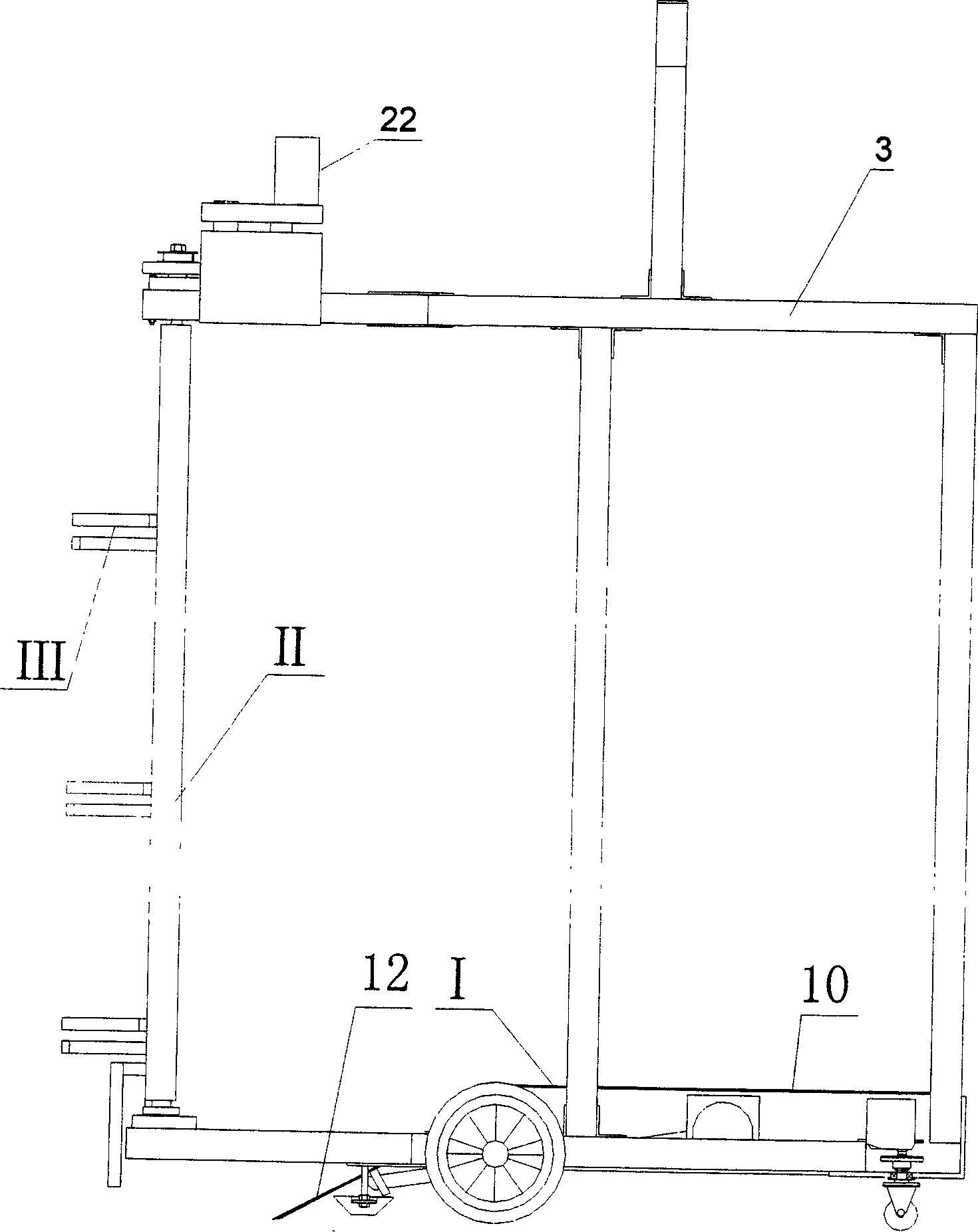

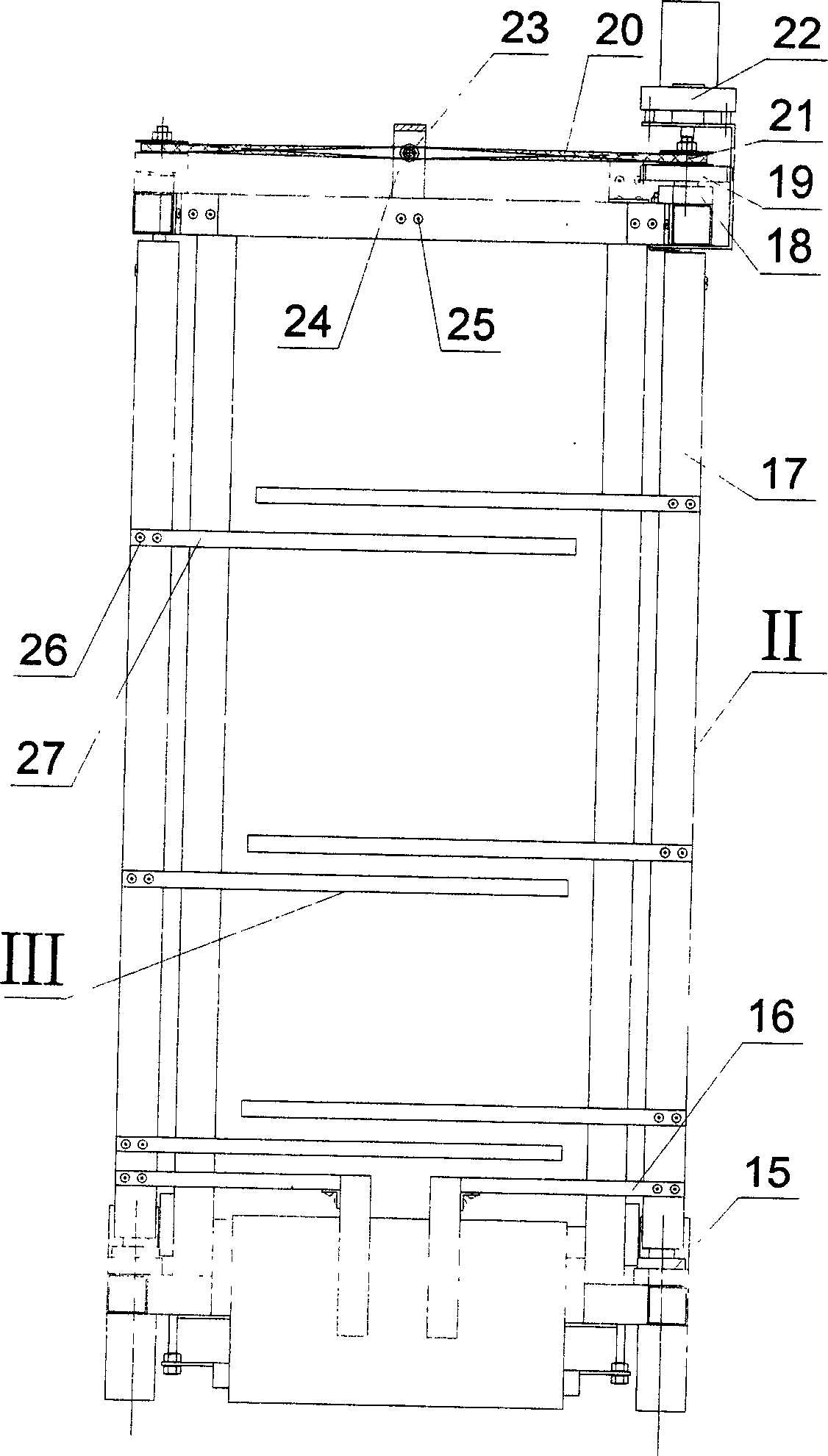

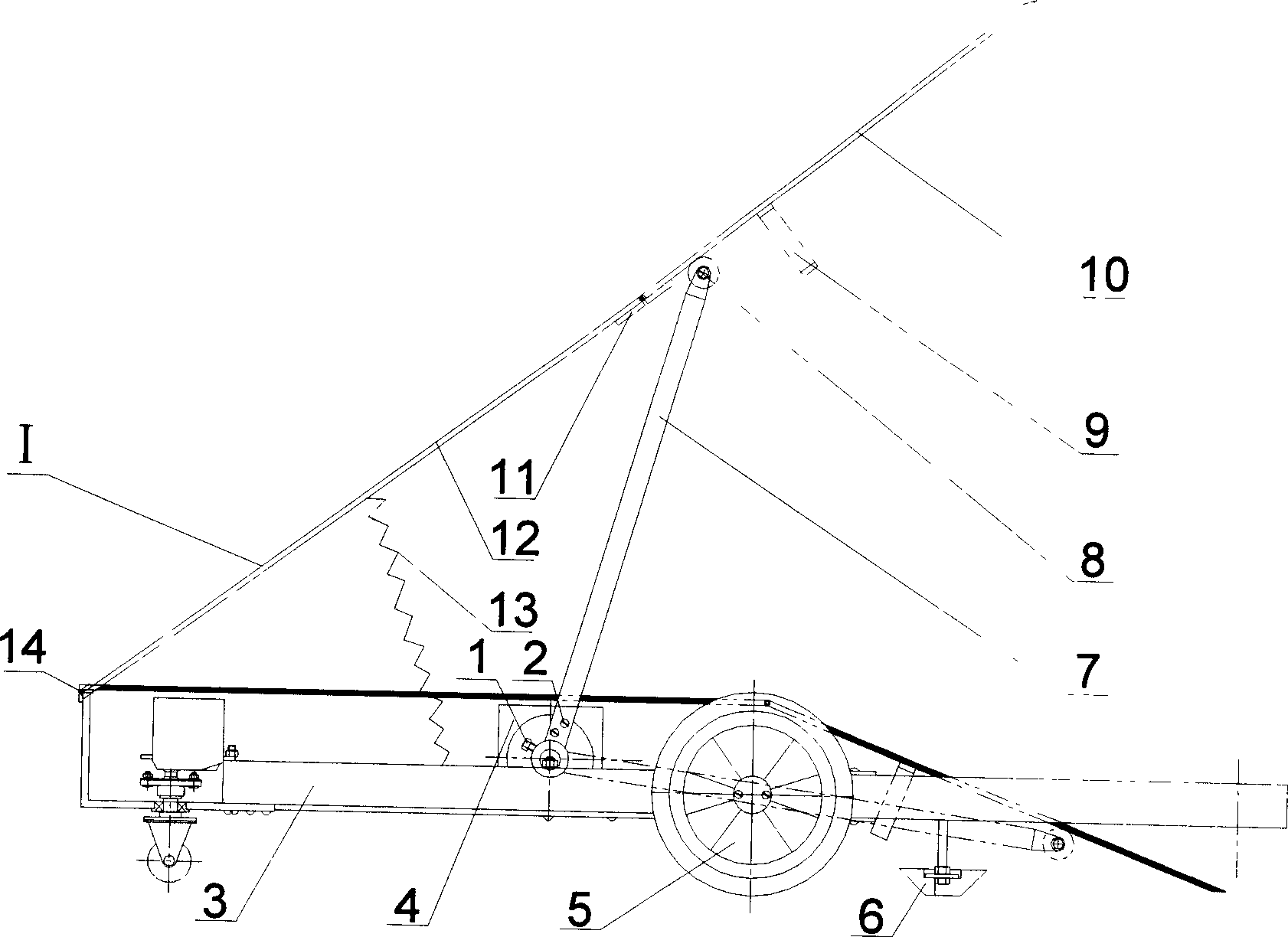

[0008] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. Before the double fork mobile dolly starts, the pick-up finger III in the double fork mechanism II is closed, as figure 2 shown. After starting, the photoelectric probe 6 on the trolley continuously detects, making the trolley move along the white guide line on the ground. Due to the adoption of closed-loop control, the driving wheel 5 can automatically rectify the deviation during the movement, so as to ensure the walking along the line. When the first position set by the program is encountered, the position of the object is judged through infrared sensor detection, and after the relative position between the trolley and the object is automatically adjusted, the drive motor 22 rotates, and the pinion in the pair of reduction gears 19 rotates , drives the gear wheel meshing with it to rotate, also drives synchronous toothed belt wheel 21 to rotate si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com