Biological oxidant capable of substituting potassium bromate for flour product

A technology of potassium bromate and flour products, which is applied in the field of food processing to achieve the effects of enhancing gluten strength, fine structure, and increasing specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

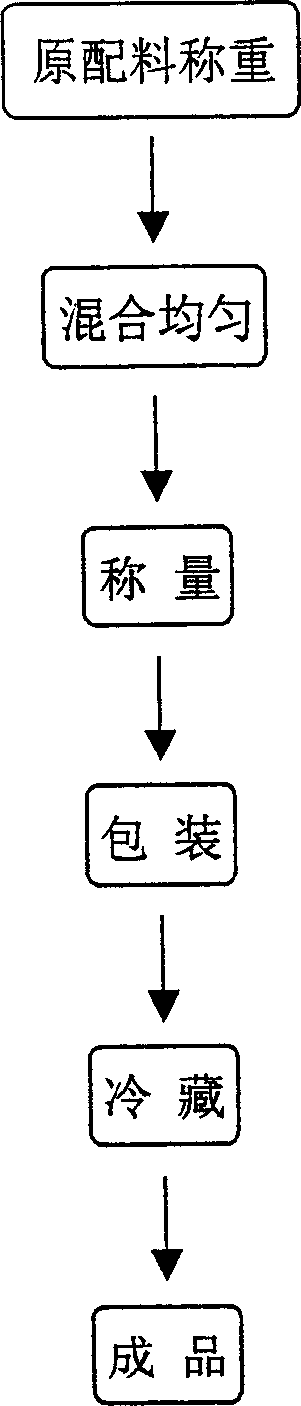

Image

Examples

Embodiment 1

[0011] In the embodiment of the present invention, glucose oxidase: 19.0% by weight, peroxidase: 22.0% by weight, and ascorbic acid: 59.0% by weight; glucose oxidase, peroxidase, and ascorbic acid are stirred in proportion at normal temperature Mix evenly in the cylinder, and the rotation speed of the mixing cylinder is: 100-120 rpm; then weigh and pack according to the packaging standard to obtain the finished oxidant. Store the packaged product in cold storage at a temperature of 0-4°C.

[0012] Take the oxidizing agent in this embodiment: 0.008% by weight, wheat flour: 51% by weight, sucrose: 10.0% by weight, salt: 0.5% by weight, milk powder: 2.0% by weight, shortening: 8.392% by weight, yeast For: 1.1% by weight, water: 27% by weight. Mix oxidant, flour, sucrose, salt, milk powder, yeast, and water, knead evenly, then add shortening and knead until a dough is formed, the dough is divided into pieces, rounded, rested and relaxed, and finally baked into bread .

[0013] ...

Embodiment 2

[0015] In the embodiment of the present invention, glucose oxidase: 19.5% by weight, peroxidase: 21.5% by weight, and ascorbic acid: 59.0% by weight; glucose oxidase, peroxidase, and ascorbic acid are stirred in proportion at normal temperature Mix evenly in the tank, the mixing speed of the mixing tank is: 100-120 rpm; then weigh and pack according to the packaging standard to be the finished oxidant. Store the packaged product in cold storage at a temperature of 0-4°C.

[0016] Take the oxidizing agent in this embodiment: 0.009% by weight, wheat flour: 51% by weight, sucrose: 10.0% by weight, salt: 0.5% by weight, milk powder: 2.0% by weight, shortening: 8.391% by weight, yeast For: 1.1% by weight, water: 27% by weight. Mix oxidant, flour, sucrose, salt, milk powder, yeast, and water, knead evenly, then add shortening and knead until a dough is formed, the dough is divided into pieces, rounded, rested and relaxed, and finally baked into bread .

[0017] Due to the additio...

Embodiment 3

[0019] In the embodiment of the present invention, glucose oxidase: 20.0% by weight, peroxidase: 22.0% by weight, and ascorbic acid: 58.0% by weight; glucose oxidase, peroxidase, and ascorbic acid are stirred in proportion at normal temperature Mix evenly in the tank, the mixing speed of the mixing tank is: 100-120 rpm; then weigh and pack according to the packaging standard to be the finished oxidant. Store the packaged product in cold storage at a temperature of 0-4°C.

[0020] In this embodiment, the oxidizing agent is: 0.01% by weight, wheat flour: 51% by weight, sucrose: 10.0% by weight, salt: 0.5% by weight, milk powder: 2.0% by weight, shortening: 8.390% by weight, yeast For: 1.1% by weight, water: 27% by weight. Mix oxidant, flour, sucrose, salt, milk powder, yeast, and water, knead evenly, then add shortening and knead until a dough is formed, the dough is divided into pieces, rounded, rested and relaxed, and finally baked into bread .

[0021] Due to the addition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com