High-efficiency energy-saving modular chamber type heat exchanger

A high-efficiency energy-saving heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problem of short strokes of primary heat medium and secondary heat medium, and shell-and-tube heat exchanger technology Complexity, CL ion content should not be too high, etc., to achieve the effect of easy disassembly, replacement and maintenance, mature manufacturing process, and scientific process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

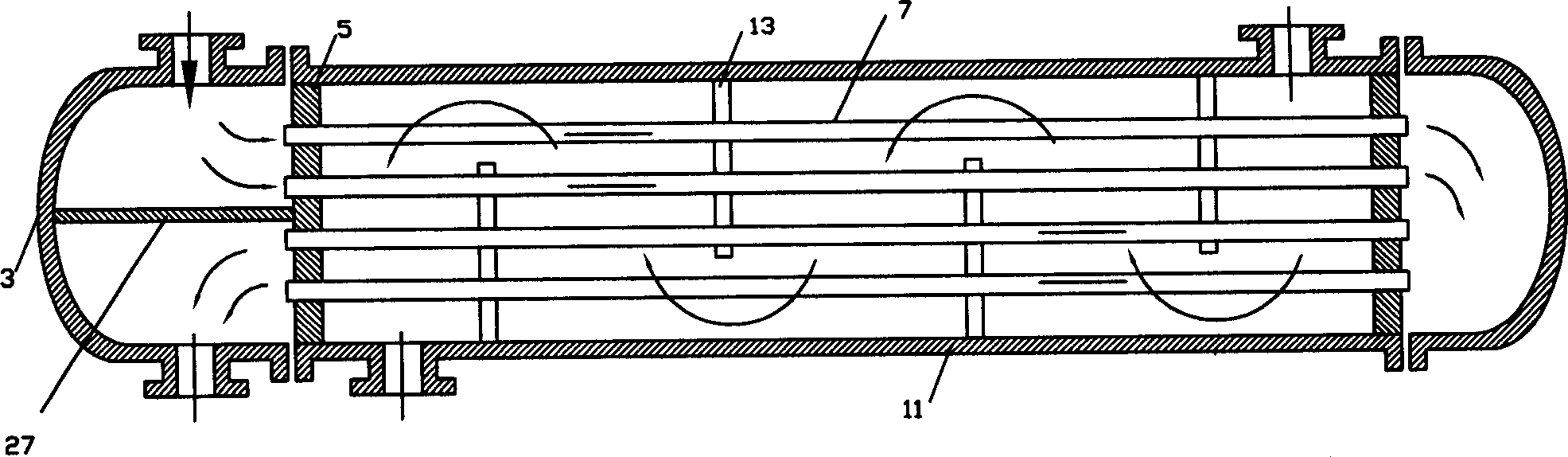

[0041] see figure 1 , the shell-and-tube heat exchanger is to connect the heat exchange tube with the tube sheet, and then fix it with the shell. Due to the structure of the shell-and-tube heat exchanger, the primary and secondary heat media are in the same box without isolation, and the inner tube The resistance is large, the pressure temperature is too high, the pressure drop loss is large, and the temperature resistance is poor. Only by adding a steam trap can it work normally, so the process is more complicated, the cost is high, and it is not durable.

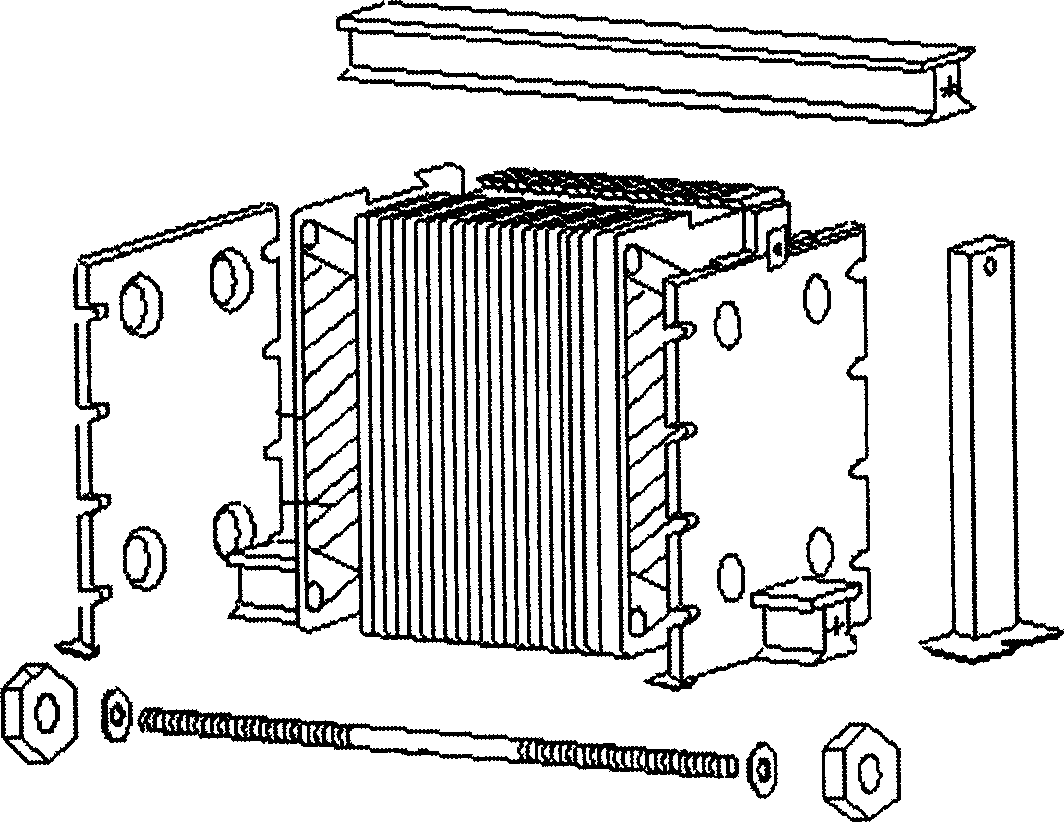

[0042] see figure 2 , the existing plate heat exchanger, because the plate heat exchanger relies on the mutual extrusion and sealing of the plates, and uses the inverted groove punched by the plates as the flow channel, the gap between the flow channels is small, and the flow is often blocked by small dirt. Therefore, the equipment needs to be cleaned frequently, which will affect the heat exchange effect and normal use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com