Three-dimensional luminophor lamp adopting light-transmitting materials for heat conduction and heat dissipation and manufacturing method thereof

A technology of light-transmitting materials and light-transmitting bodies, which is applied to optical elements for changing the spectral characteristics of emitted light, semiconductor devices of light-emitting elements, lighting and heating equipment, etc. Narrow and other problems, to solve the problem of blue leakage, improve uniformity and high luminous flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

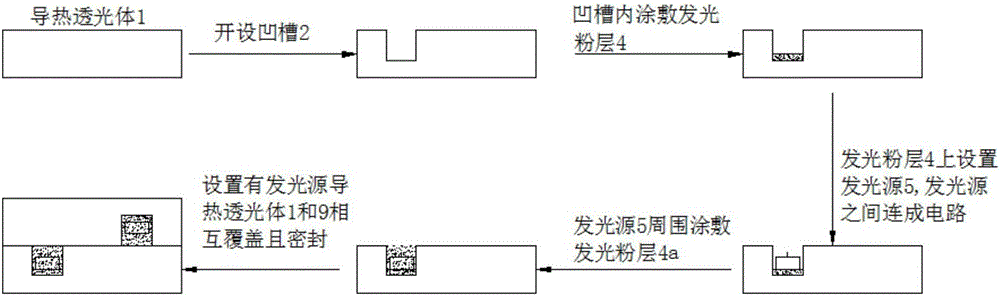

[0056] A method for manufacturing a three-dimensional illuminant lamp utilizing light-transmitting materials for heat conduction and heat dissipation, such as Figure 1A As shown, the steps include: opening a groove 2 on the heat-conducting light-transmitting body 1, coating the first layer of luminescent powder layer 4 on the bottom plane of the groove 2, setting a light-emitting source 5 on the luminescent powder layer 4, and coating Covering the second luminescent powder layer 4a, the translucent body 1 provided with the luminescent source and the translucent body 9 provided with the luminous source cover and seal each other.

Embodiment 2

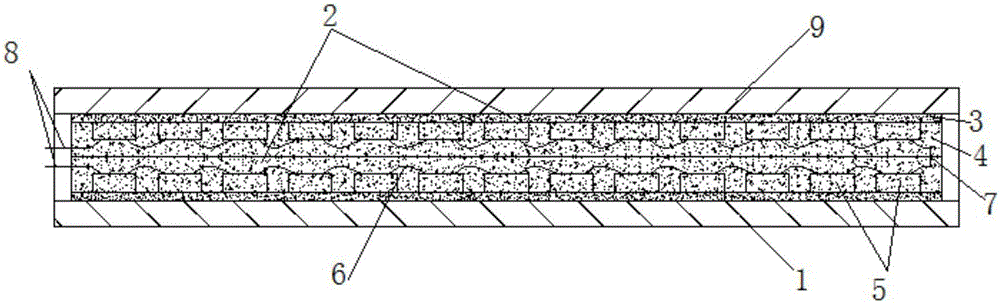

[0058] A kind of three-dimensional illuminant lamp that utilizes light-transmitting material to conduct heat and dissipate heat described in Embodiment 1, such as Figure 1B as shown, Figure 1B for Figure 1A Axial cross-sectional view of the fabricated high-flux 3D luminous body lamp

Embodiment 3

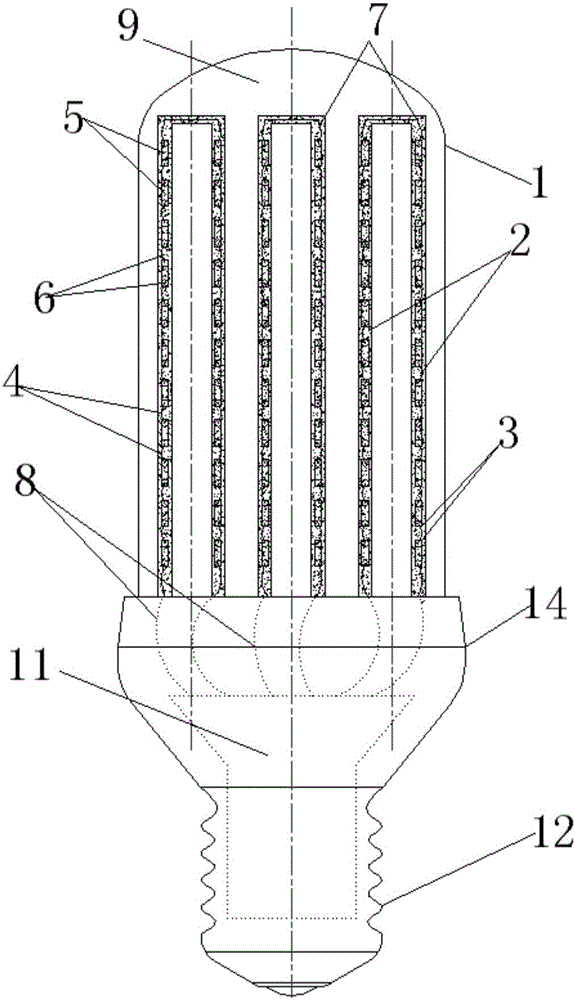

[0060] A kind of three-dimensional illuminant lamp that utilizes light-transmitting material to conduct heat and dissipate heat described in Embodiment 1, such as figure 2 as shown, figure 2 It is a T-shaped high luminous flux three-dimensional luminous body lamp, including a light source 5 arranged inside a sealed heat-conducting light-transmitting body 1 and a heat-conducting light-transmitting body 9, a driver 11, a driver housing 14, an electrical connector 12; the heat-conducting light-transmitting body 1 and A groove 2 is provided on the heat-conducting light-transmitting body 9, the inner surface of the groove is coated with a first layer of luminescent powder layer 3, and a light-emitting source 5 is arranged on the luminescent powder layer, and the light-emitting sources are connected in series or in parallel or in series-parallel through electrical connecting wires 6 connection, the electrodes 7 at both ends of the electrical connecting line are connected to the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com