Making method for optical disk recording media

A manufacturing method and optical disc technology, which are applied in the fields of optical record carrier manufacture, optical record carrier, recording/reproducing by optical method, etc., and can solve problems such as inability to set recording film coating and increase of recording medium capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Referring to the accompanying drawings, the embodiment of the method for making an optical disc recording medium of the present invention will be described in detail.

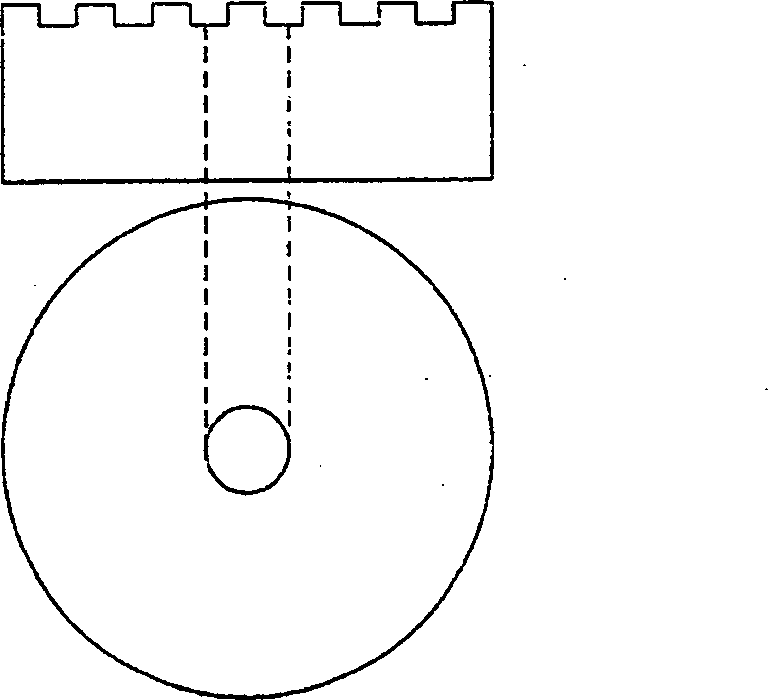

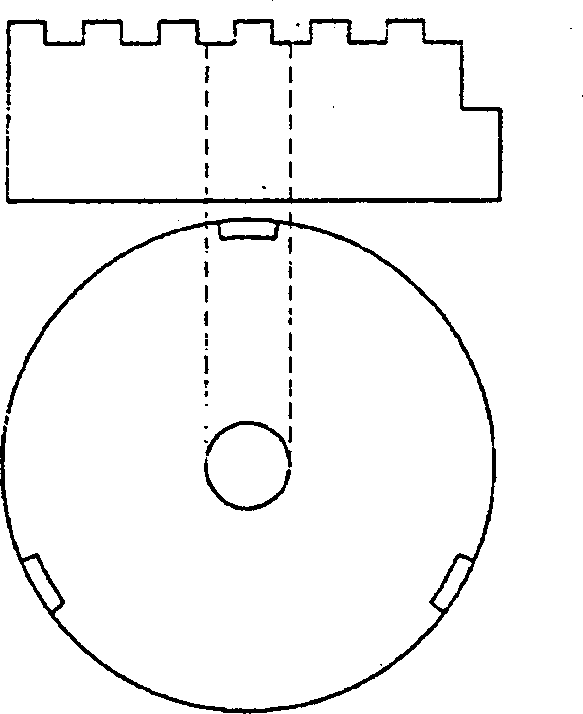

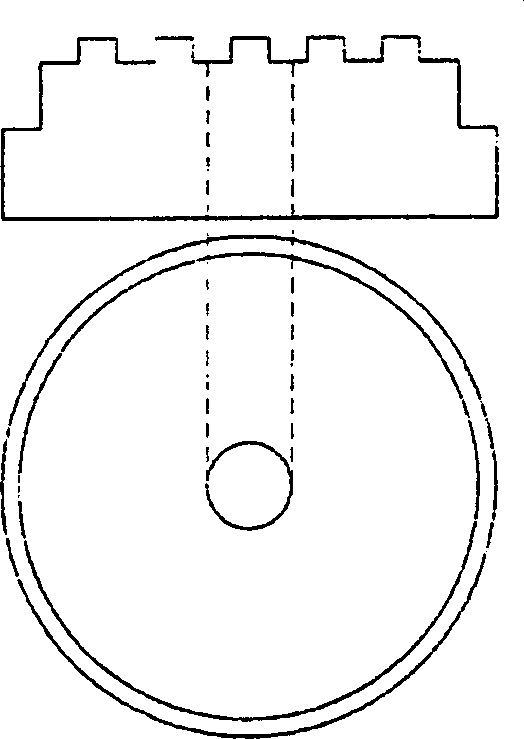

[0050] Figure 1a to Figure 1d It is a composition diagram showing the shape of the stamper used for recording media of the present invention; Figure 2a and Figure 2b It is a configuration diagram of a stamper forming a separation-promoting layer and a polycarbonate base plate forming a multilayer film.

[0051] In a given area within a certain radius, the present invention only uses the same recording and reading technology as before, so that the recording density can be doubled. In the present invention, a separation layer is firstly arranged on the first recording film, and then the second recording film is inserted below it, and the above steps are repeated, so that the recording density can be doubled.

[0052] First, the process of forming a substrate with a stamper and a multilayer film for maki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com