Video camera reference method only using plane reference object image

A technology for calibrating objects and cameras, which is applied in the field of camera calibration and geometric correction of images, which can solve the problems of difficult to determine the impact and low efficiency, and achieve the effects of improving calibration accuracy, simplifying the calibration process, and improving calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

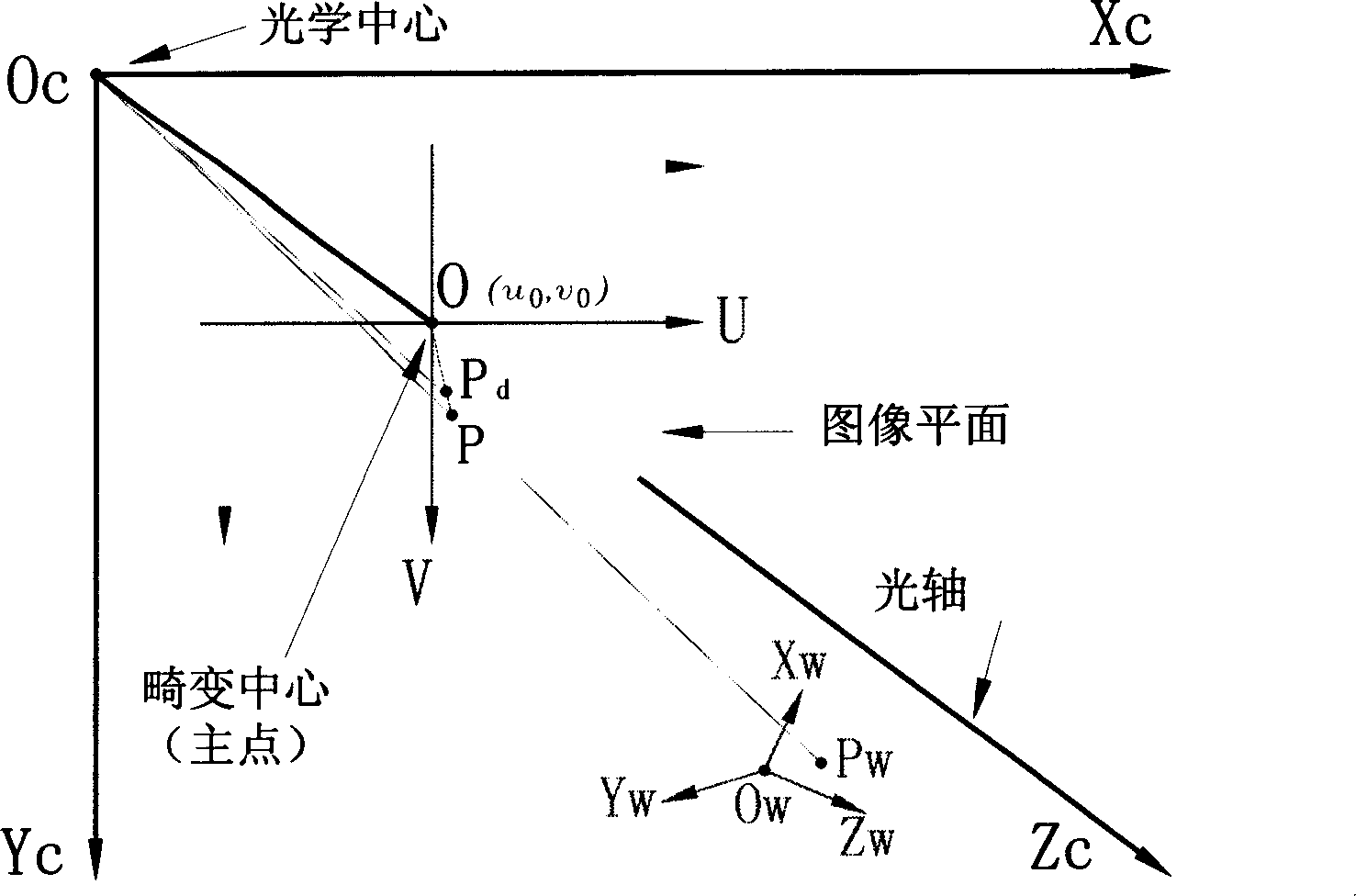

[0019] In order to better understand the technical solutions of the present invention, a further detailed description will be made below in conjunction with the accompanying drawings and embodiments.

[0020] Camera calibration method of the present invention comprises the following steps:

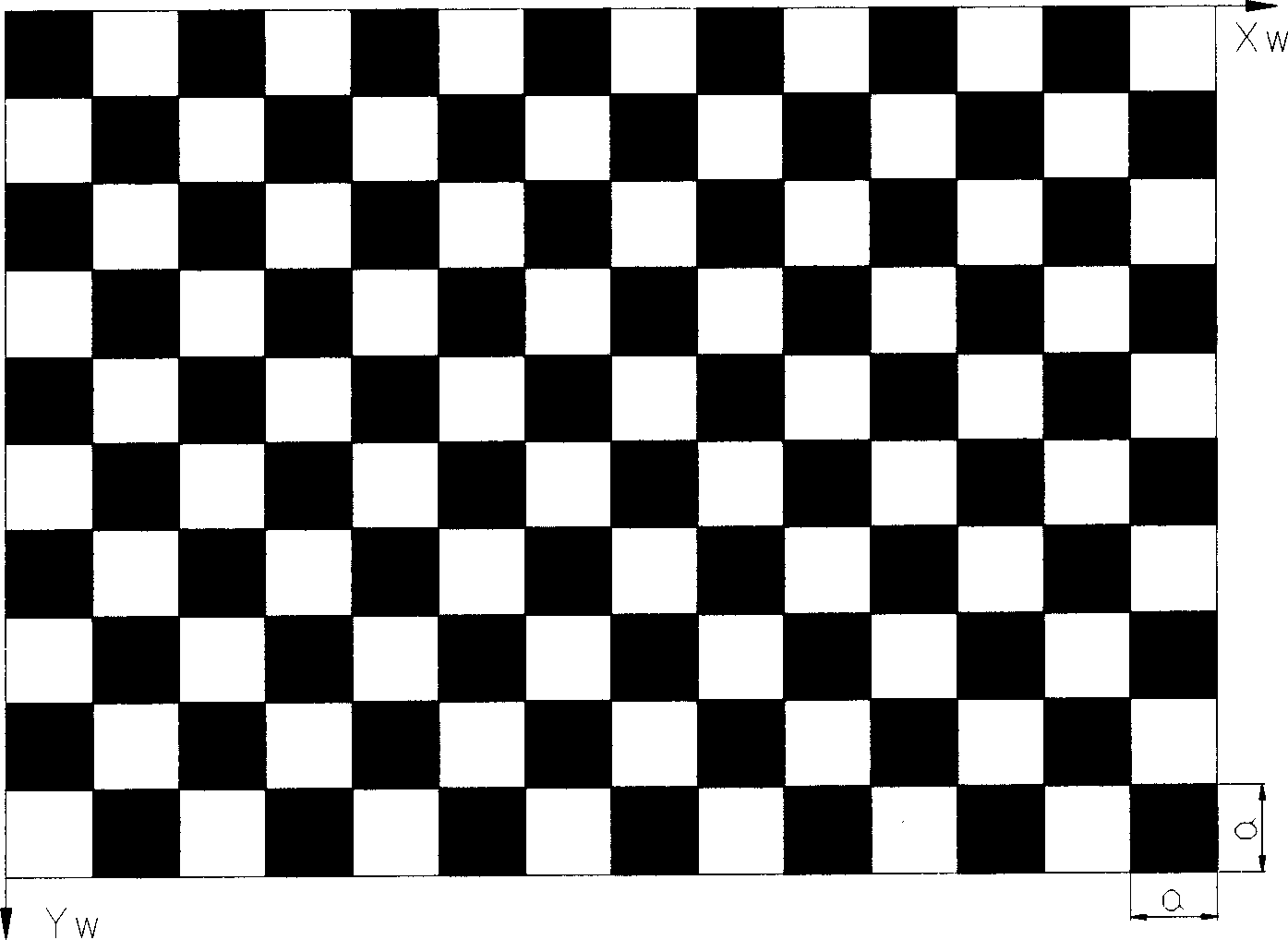

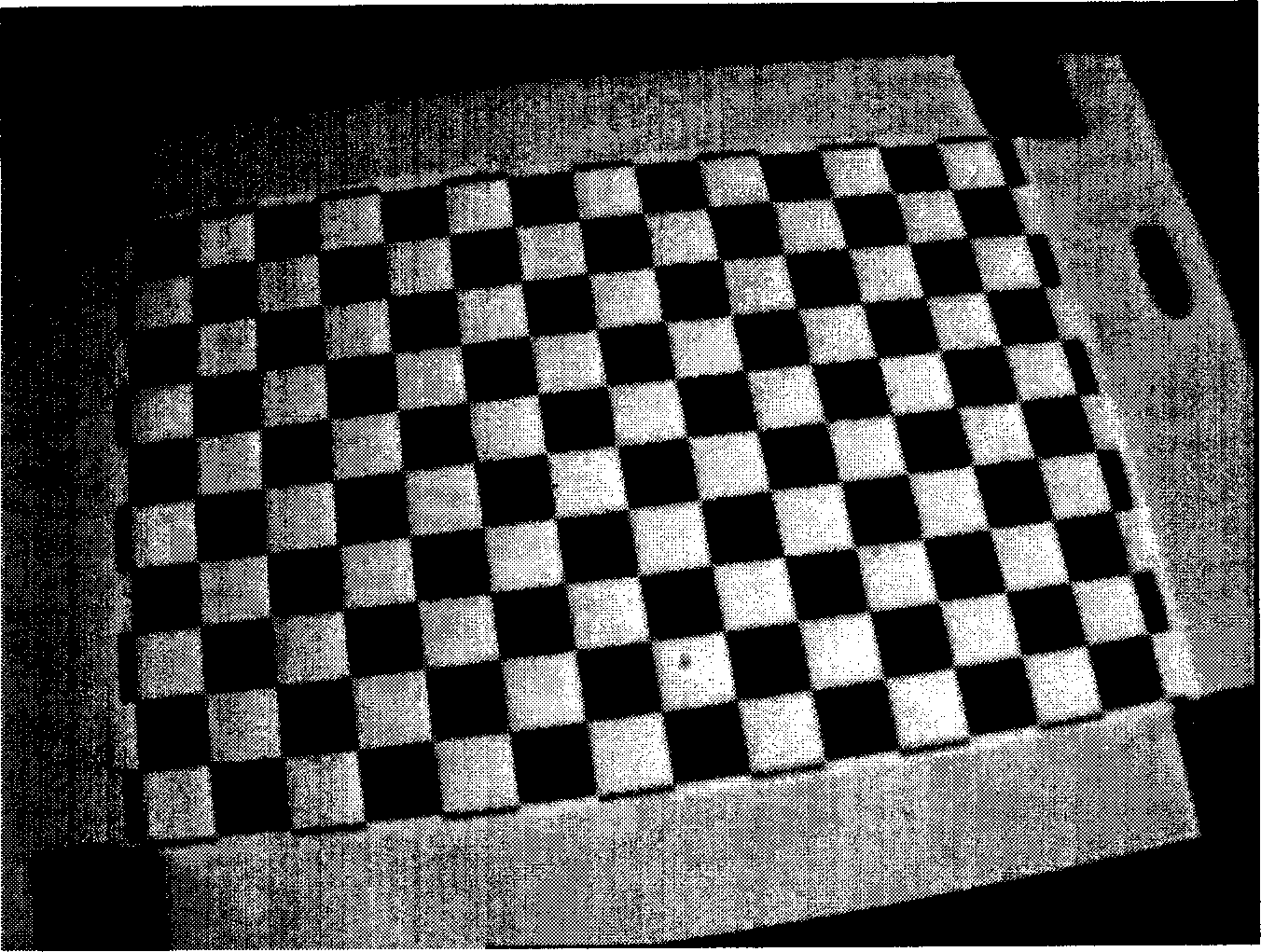

[0021] 1. Set the plane calibration object: Set two sets of parallel straight lines on a plane object as the plane calibration object. The two sets of parallel lines are perpendicular to each other, and the distance between the parallel lines in each group is known, so that the side length is known. flat grid graphics. The side length of the grid pattern changes according to the nominal focal length of different camera lenses. The smaller the nominal focal length, the larger the side length of the square pattern, and vice versa, so that when the image of the plane calibration object is taken, the camera and calibration The distance between objects is within the working range of the actual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com