Method of removing organic sulfur compounds from alkylate

A technology of organic sulfur and compounds, applied in the field of processing alkylation products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

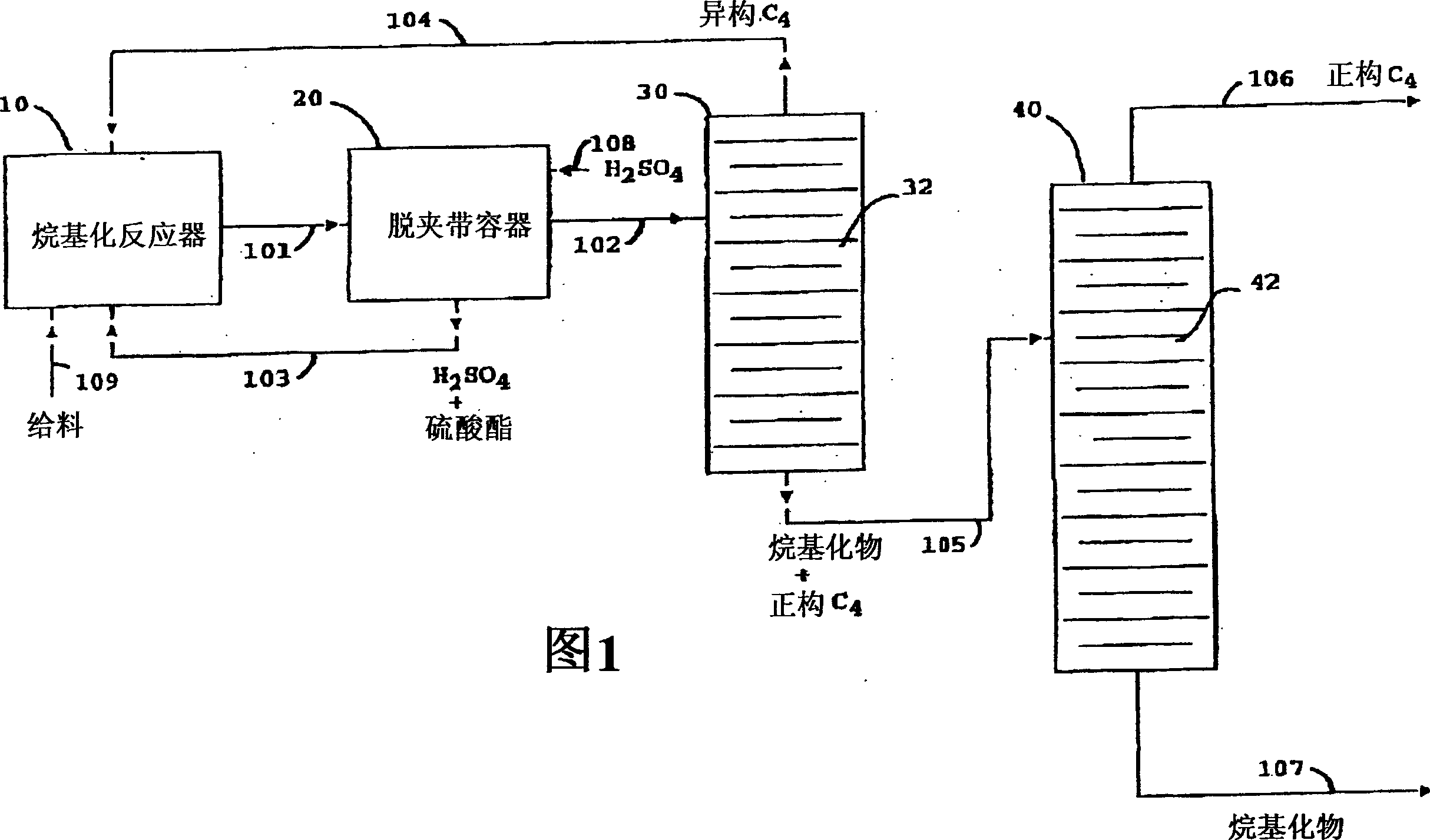

Image

Examples

Embodiment

[0017] Crude alkylate containing about 22% normal C4 was blended with butyl bisulfate to 31.5 wppm total sulfur. This feed is processed in three ways:

[0018] 1) Untreated filler

[0019] The feedstock was first flowed vertically at approximately 20 LHSV (liquid hourly space velocity) (approximately 600 cc) through a 6 foot by 1 / 2 inch Teflon tube filled with untreated fiberglass / 305SS co-braided de-entrainment material. The effluent has the same sulfur content as the feed.

[0020] 2) by H 2 SO 4 wet filler

[0021] Fill the bottom 2 / 3 with 98% H 2 SO 4 Wet, and drain filling completely. Feedstock flows up through the packed 6 inch tube at about 20 LHSV (about 1400 cc). Using only 2 / 3 of the bed, the effluent contains only 1.3 (at 1000 cc) - 1.6 (at 1400 cc) wppm of total sulfur.

[0022] 3) Section H 2 SO 4 processing method

[0023] Combine 65cc of feed with 10cc of 98% H 2 SO 4 Shake vigorously together for about 1-2 minutes and allow the phases to separate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com