Internal gear type tamping tool for horizontal coke oven

A technology of internal gear and tamping machine, which is applied in the mechanical treatment of coal loaded into the furnace, coking oven, petroleum industry, etc., and can solve problems such as affecting the normal operation of the tamping machine, difficulty in adjusting the hammer, and increasing product costs. , to achieve the effect of simple structure, easy maintenance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

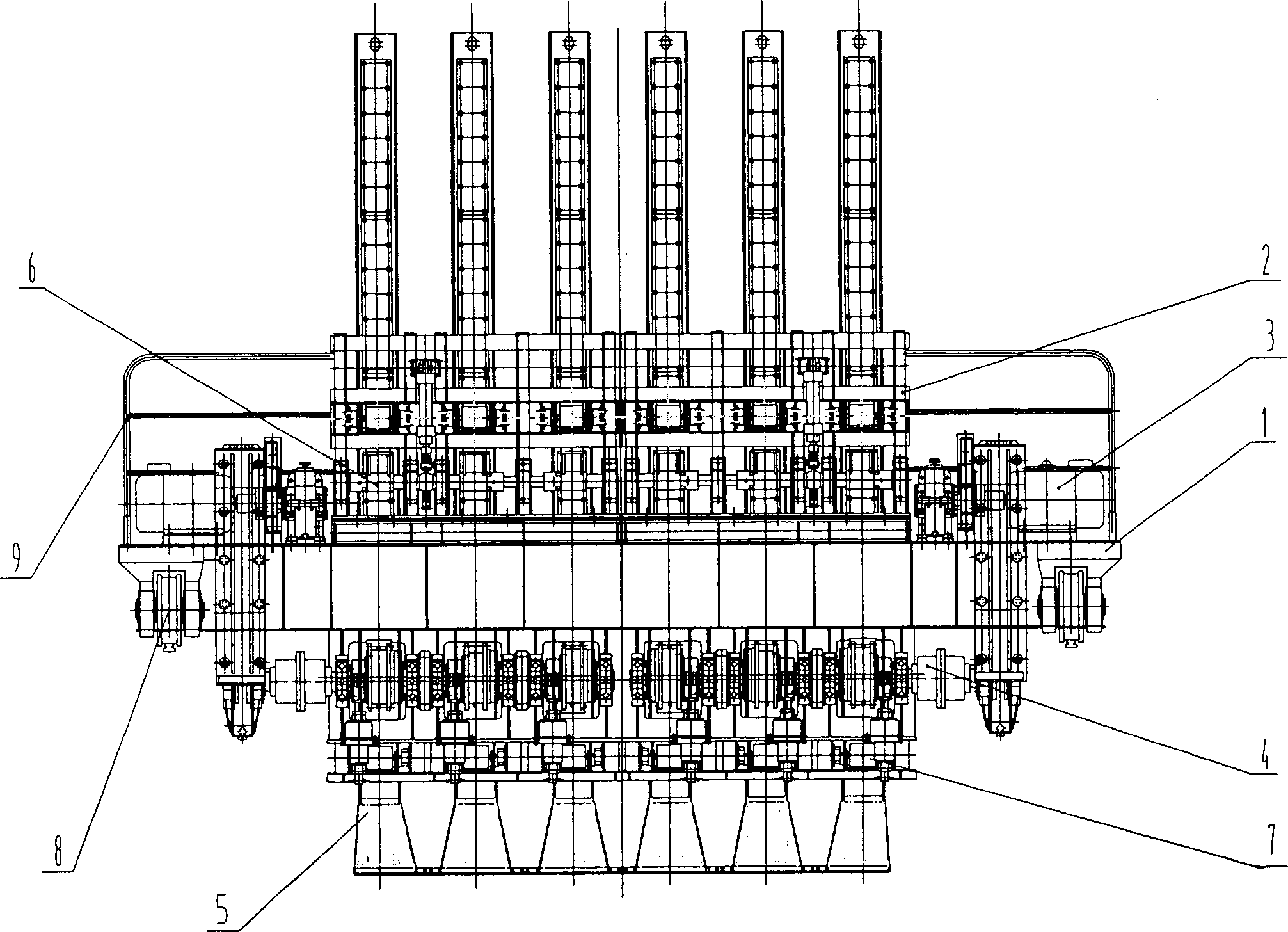

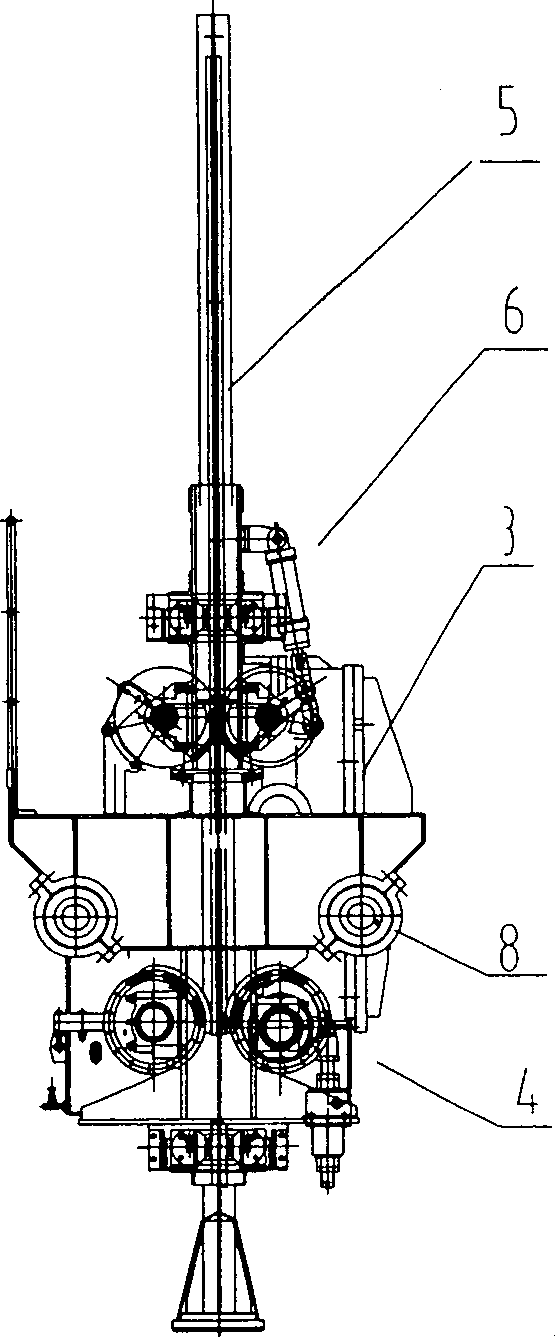

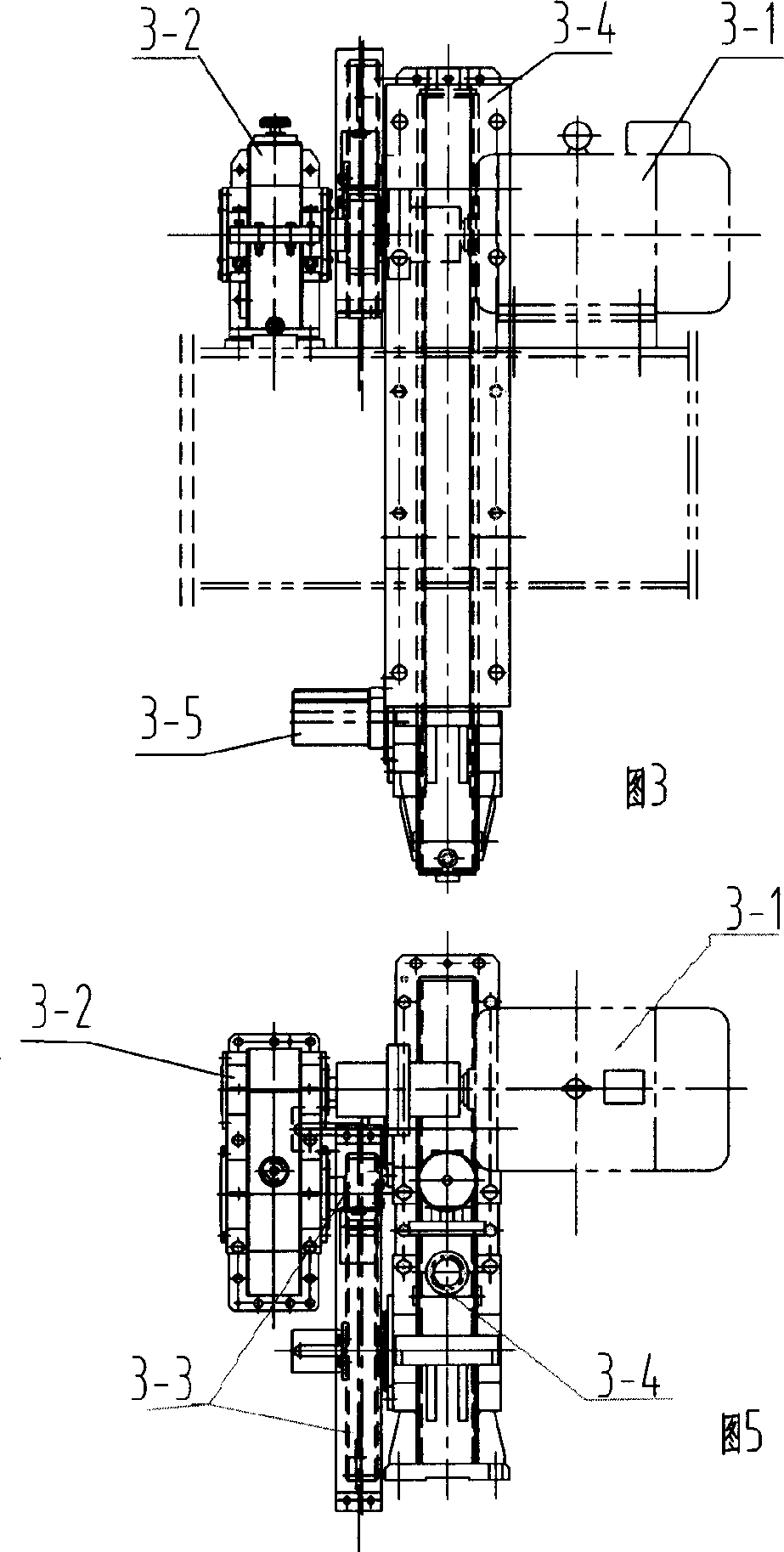

[0029] Such as figure 1 , 2 Shown: an internal gear tamping machine for horizontal coke ovens, consisting of trolley frame 1, upper bracket 2, two sets of transmission devices (horizontally symmetrical distribution) 3, two sets of clamping hammer devices (horizontally symmetrical distribution) 4. Six tamping hammers 5. Two sets of hammer stop devices (horizontally symmetrical distribution) 6. Six sets of guide devices on the upper and lower sides 7. Four sets of operating mechanisms 8 and railings 9. The transmission device 3, the clamping hammer device 4, the operating mechanism 8 and the railing 9 are installed on the trolley frame 1. The hammer stop device 6 is installed on the upper support 2, and the upper guide and the lower guide 7 are respectively installed on the upper support 2 and the trolley frame 1. After six tamping hammers 5 are respectively clamped by two sets of hammer stop devices 6, they can be suspended on the trolley frame 1.

[0030] Such as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com