Tail rudder operated rotor flying robot

A flying robot and tail rudder technology, applied in the field of robotics, can solve the problems of inconsistent hysteresis effect, uncertain flight control, and difficulty in miniaturization, and achieve the effect of improving the design mode, reducing the difficulty of miniaturization, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

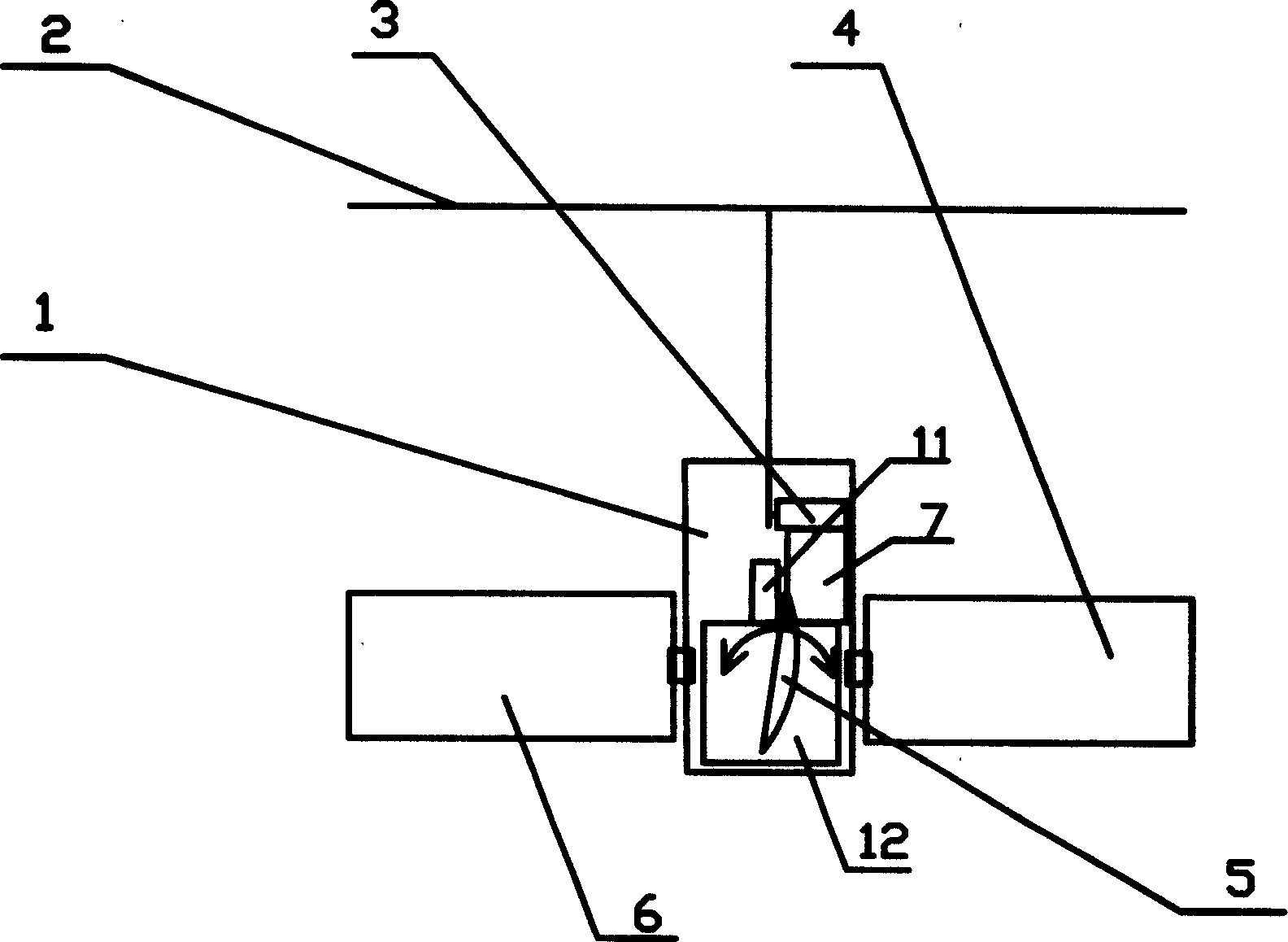

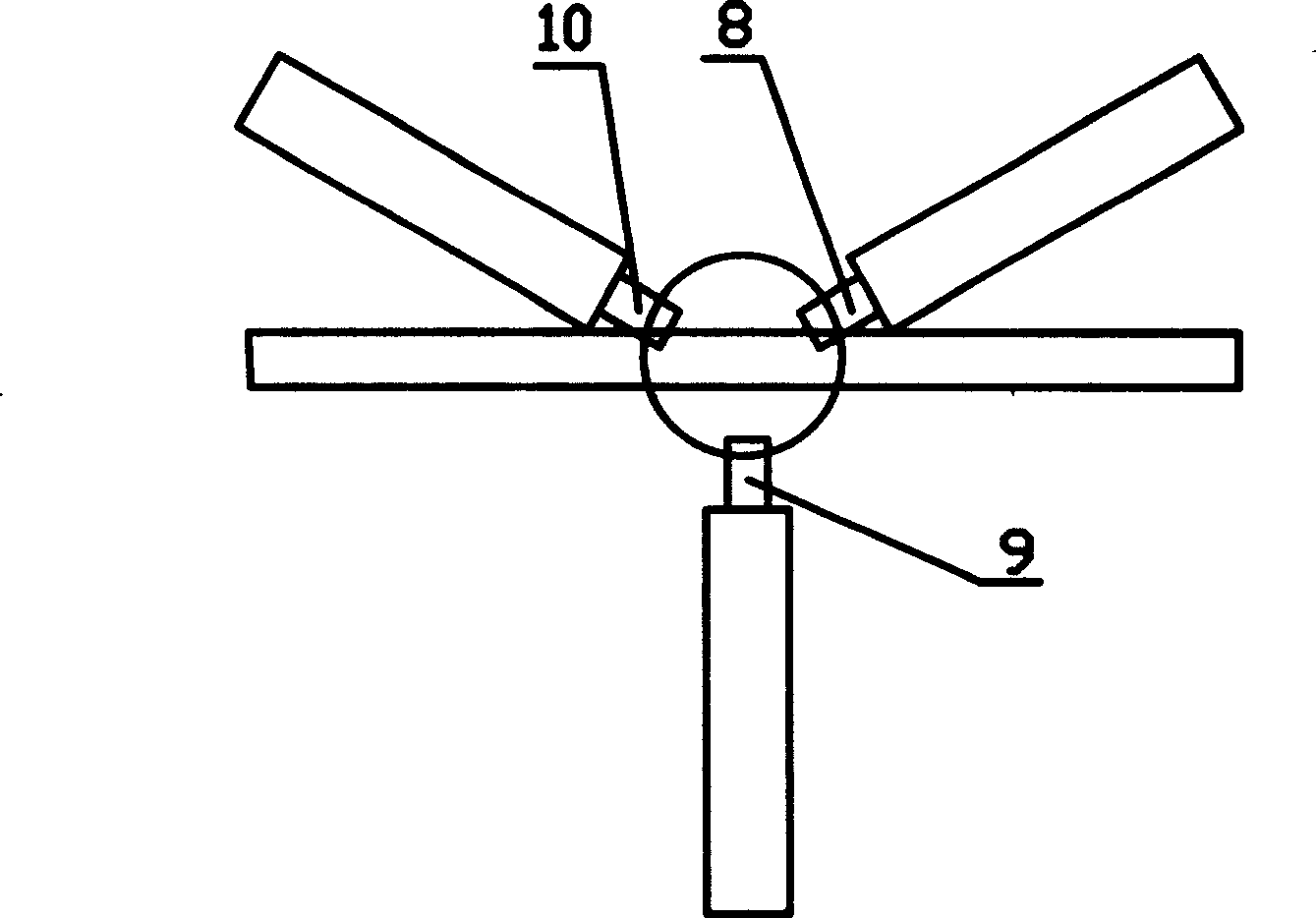

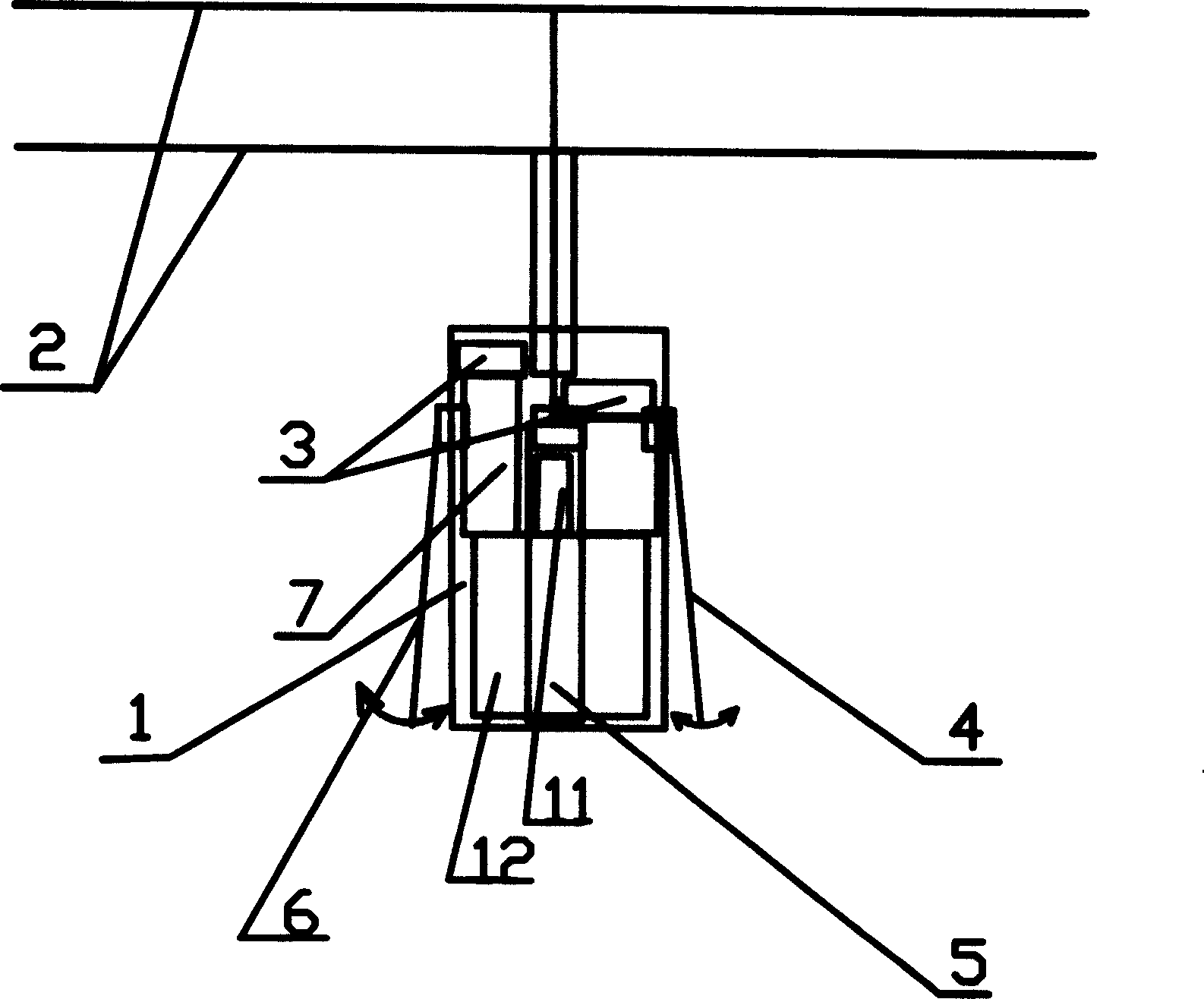

[0012] like figure 1 , 2 As shown, the present invention includes: body 1, rotor 2, rotor controller 3, rudder 4, rudder 5, rudder 6, rudder controller 7, rudder driver 8, rudder driver 9, rudder driver 10. Attitude sensor 11 and power source 12. The connection relationship is: the rotor drive controller 3 is directly fixed on the body 1, controlled by the PWM mode of the DC motor, and its output terminal is fixedly connected with the rotor 2. The tail rudder controller 7, the tail rudder driver 8, the tail rudder driver 9, and the tail rudder driver 10 are arranged below the body 1, and the tail rudder controller 7 automatically generates the tail rudder drive command according to the information of the attitude sensor 11 and the order of the operator, The tail rudder 4 is set at the output end of the tail rudder driver 8, the tail rudder 5 is set at the output end of the tail rudder driver 9, the tail rudder 6 is set at the output end of the tail rudder driver 10, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com