Mini-type bi-pole single-phase generator rotor

A single-phase generator and two-pole technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of weakening the main magnetic field, increasing the output of the prime mover and the burden of the excitation system, and increasing the temperature of the rotor, etc. problems, to achieve the effect of improving stability and reliability, reducing temperature rise, and reducing rotor temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

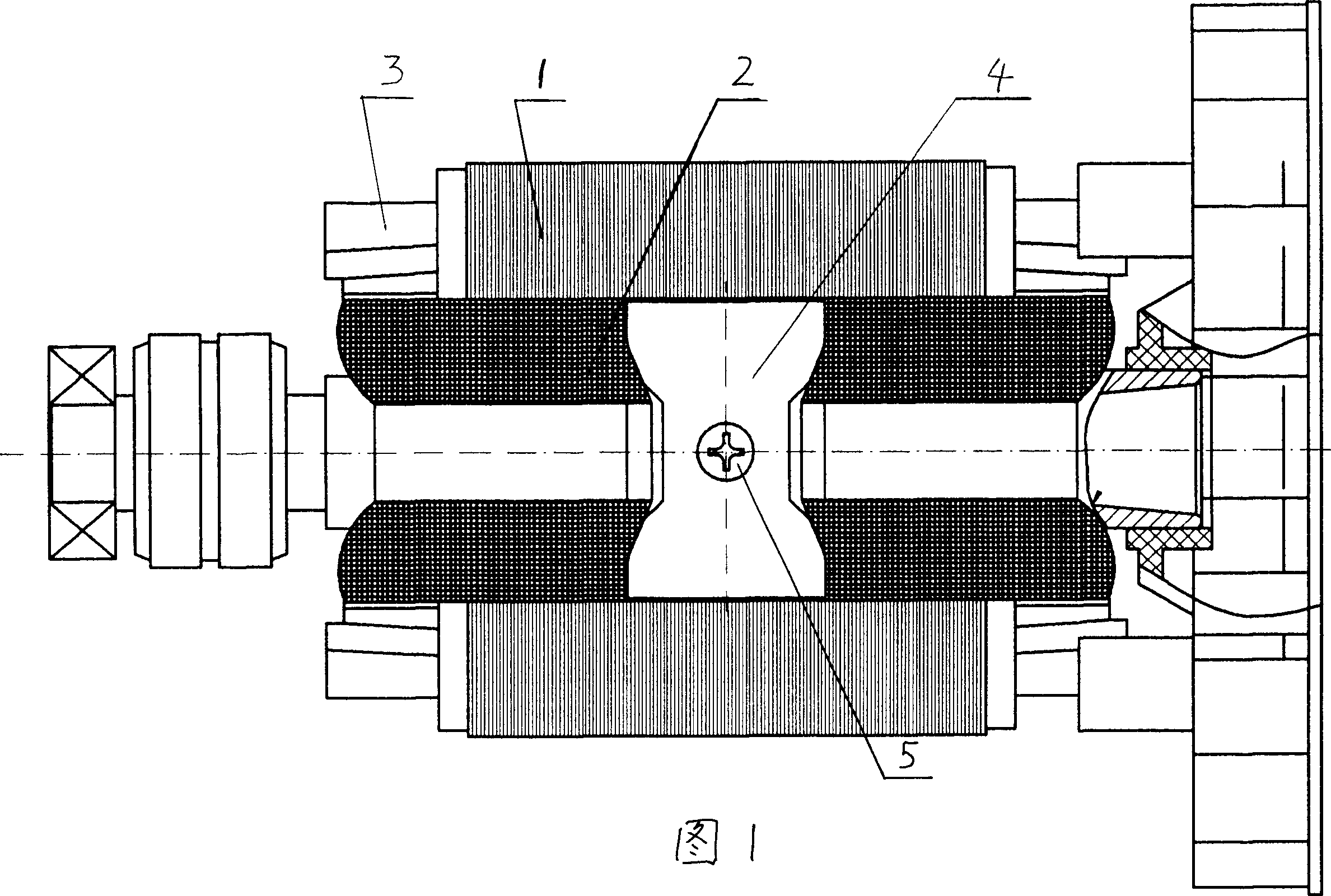

[0011] Embodiment 1: As shown in Figure 1, the small two-pole single-phase generator rotor of the present invention has an iron core 1, a winding coil 2, an insulating framework 3 and a pressing plate 4, and the winding coil 2 bypasses the insulating framework 3 and passes through the pressing plate 4 Use the bolt 5 to press tightly in the embedding groove of the iron core 1, and the material of the pressing plate 4 is stainless steel.

[0012] In order to illustrate its technical effect, the same stator is used on a small two-pole single-phase generator with an output power of 2KW, an output frequency of 50HZ, and an output voltage of 220V / 110V, and the rotor winding pressure plate 4 is made of carbon steel and stainless steel. Comparative Test. Among them, the load is a pure resistive light bulb, using the same power, the test tool is Aino 2103B electrical parameter comprehensive tester and mercury thermometer, and the test environment is indoor. The relevant parameters of ...

Embodiment 2

[0016] Embodiment 2: The structure is the same as that of Embodiment 1, except that the material of the pressing plate 4 is copper. Contrast test method, test environment, instrument used and product relevant parameter are identical with embodiment 1, and its each performance index detection result contrast is as follows:

[0017] Rotor winding pressure plate is carbon steel

Rotor winding pressure plate is stainless steel

Stator temperature rise (K)

90.71

85.94

Rotor temperature rise (K)

97.02

90.88

output power(W)

2083

2263

Secondary winding voltage (V)

76.3

66.1

Excitation voltage (V)

65.0

51.2

1.47

1.21

[0018] It can be seen from the above table that after the winding pressure plate 4 is made of copper, the temperature rise of the stator is reduced by 5.2%, the temperature rise of the rotor is reduced by 6.3%, the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com