Delivery system for glass substrates or articles like these

A conveying system and glass substrate technology, which is applied in the field of conveying systems, can solve the problems of low substrate storage density, failure to increase productivity, loss of production cycle time, etc., and achieve the effects of high compactness, space saving, and increased storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

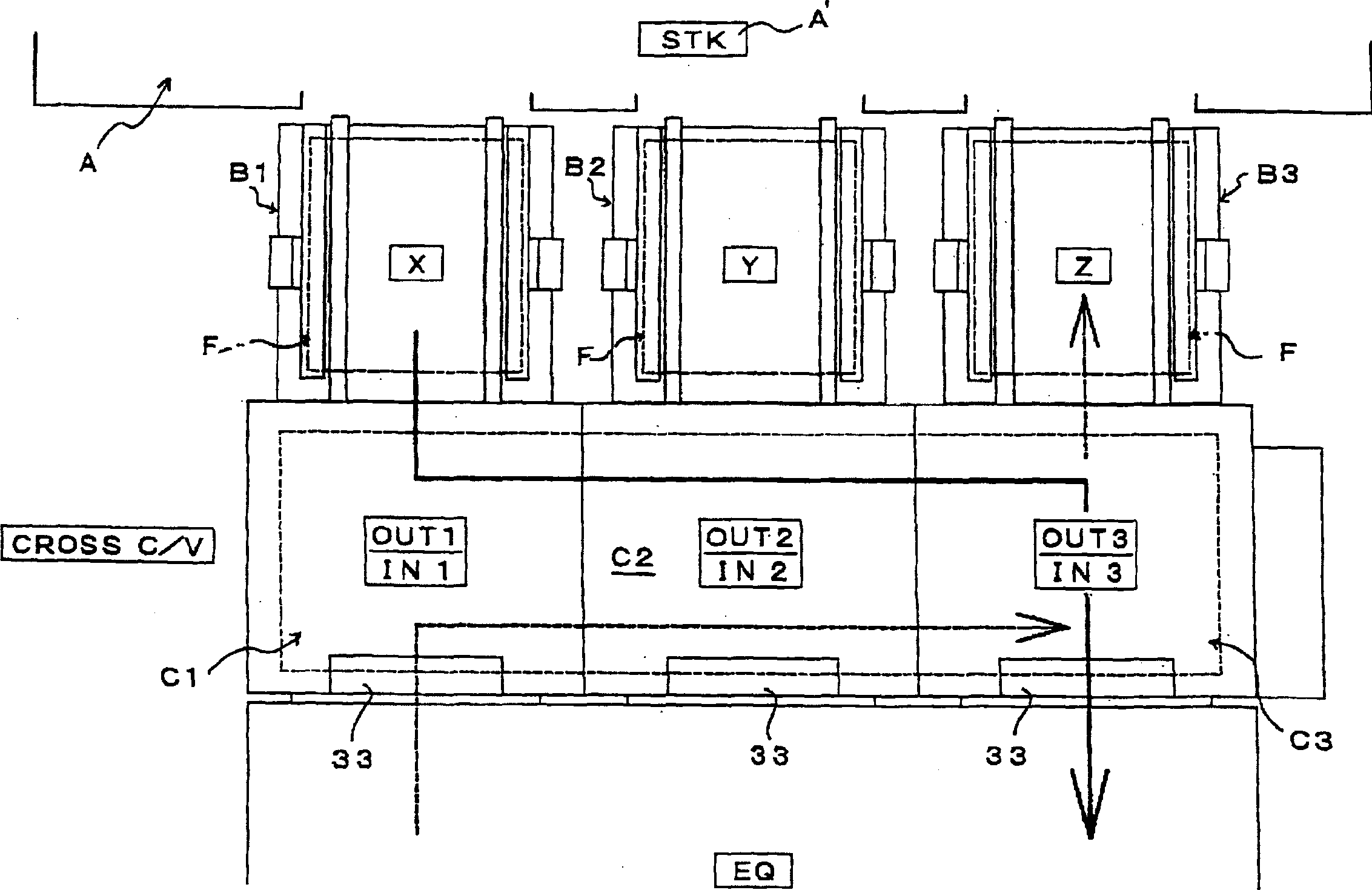

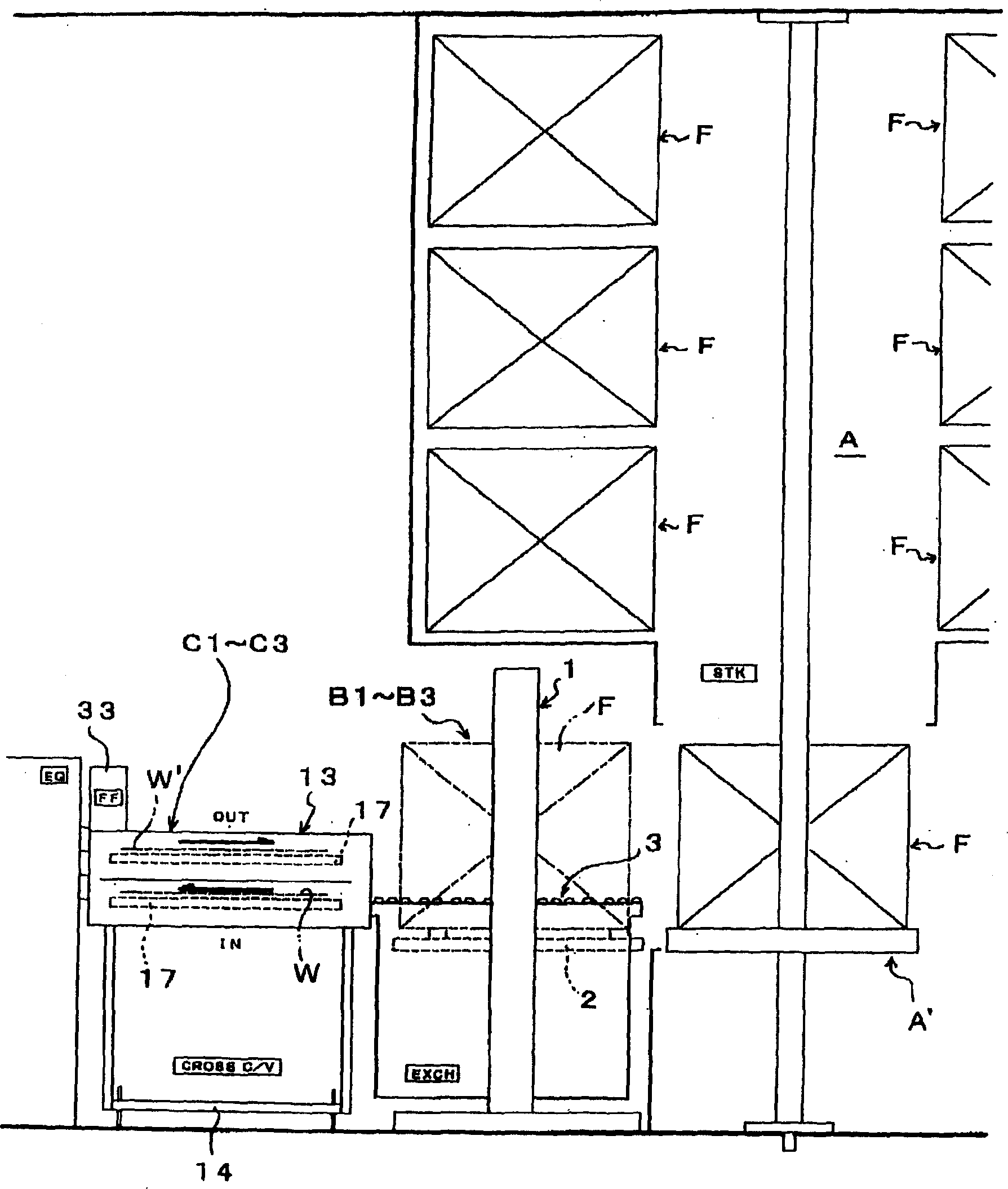

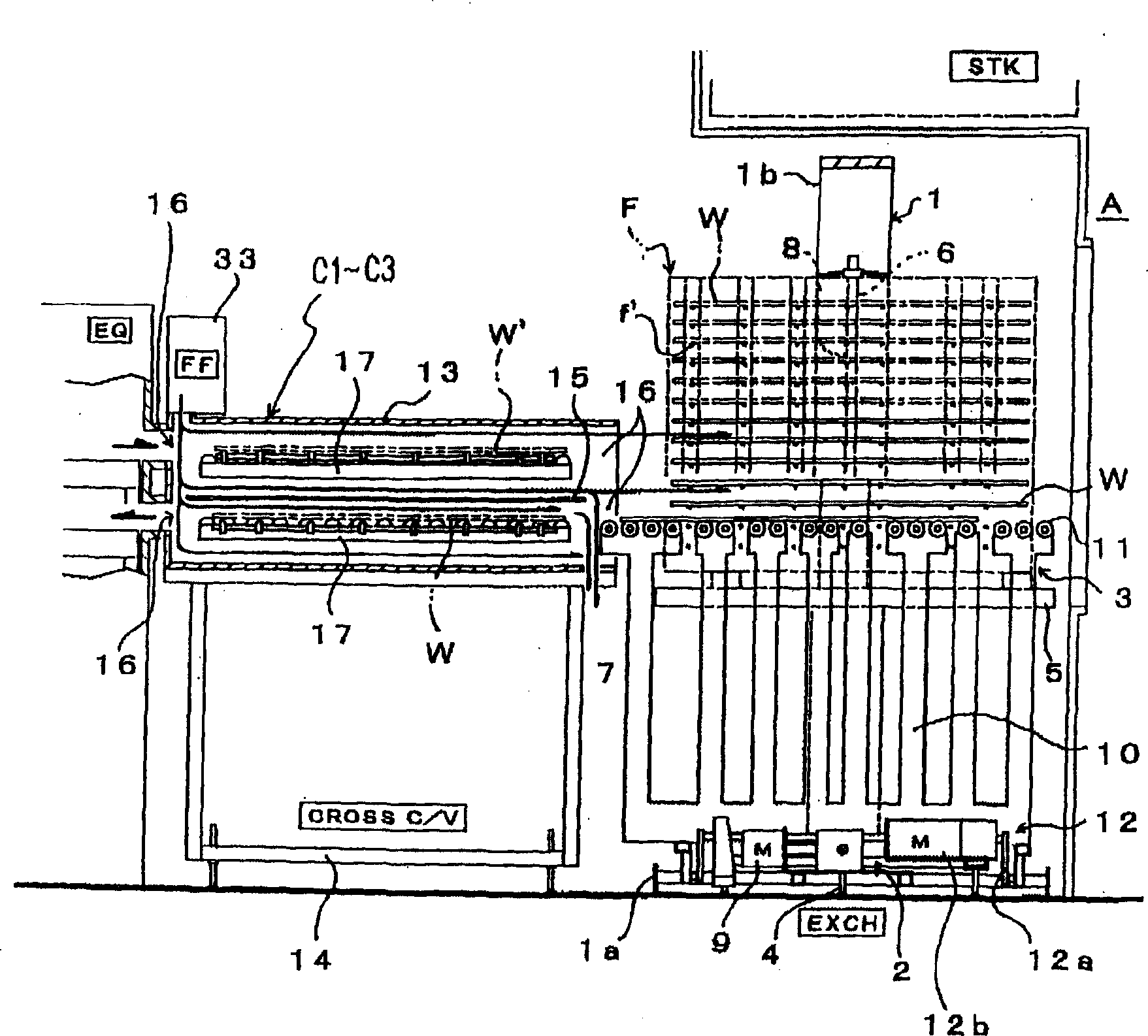

[0040] Next, an example of an embodiment of the conveyance system of the present invention in the case where the conveyance device for cassettes is an automatic warehouse (stacking crane) will be described with reference to the drawings.

[0041] figure 1 and figure 2 The general configuration of the conveying system installed in the clean room is shown. Along the stacking crane A' of the automatic warehouse A, a plurality of (three in the figure) exchange devices B1, B2, and B3 are arranged side by side in a straight line. Correspondingly, two-layer conveyors C1, C2, and C3 are arranged side by side on the loading and processed workpiece W' or the unloading workpiece W side (the side opposite to the stacking crane side) of the exchange devices B1-B3, and the two-layer conveyor C1, C2, and C3 divide the transfer special conveyor and the receiving special conveyor into upper and lower two-level configurations. The special transfer conveyor transfers the workpiece to the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com