Universal chemical process CO2 generator

A chlorine dioxide and chemical method technology, applied in chlorine oxide and other directions, can solve the problems of increasing capital occupancy, difficult management of equipment, complicated equipment selection, etc., and achieve the effects of simple structure, good economic benefits, and water conservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

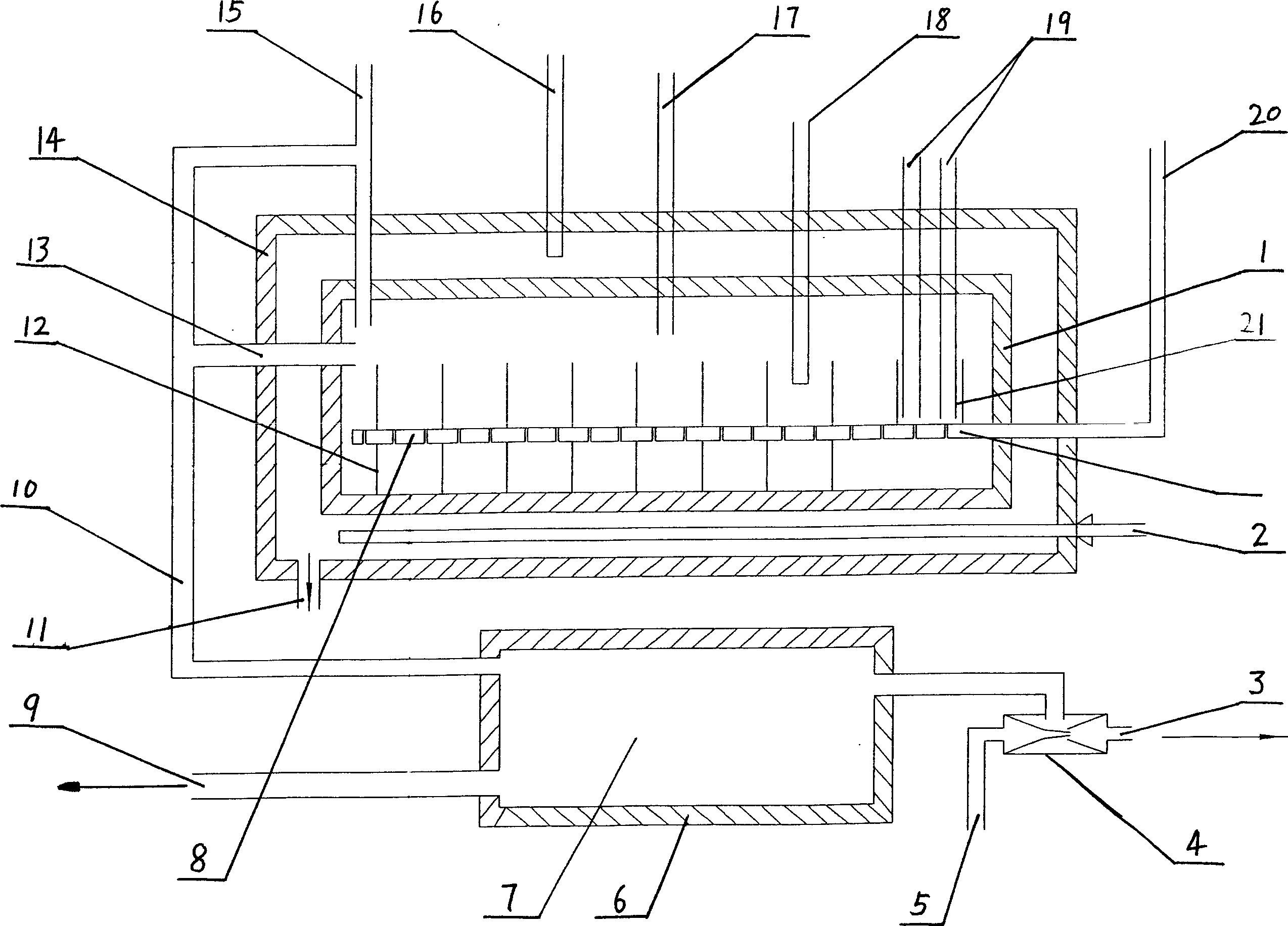

[0015] As shown. The general chemical chlorine dioxide generator includes a reactor 1, an air distributor 8, a reaction material mixer, a heating water tank 14, and other parts.

[0016] The invention adopts a negative pressure aeration process, and the reactor 1 is fixed horizontally, with right in and left out. The tubular or box-shaped reactor 1 is arranged transversely in the water tank and has a gap with the inner wall of the water tank 14. The water in the gap is the heat medium. The heating end of the heating tube 2 is set between the bottom of the reactor 1 and the water tank, and the heating tube 2 The end is fixed on the water tank. The right end of the reactor 1 passes through the water tank 14 and communicates with the two reaction material inlets 19 and the air distributor 8 provided with the reactor cavity; the other end is located in the upper part of the reactor cavity with a water tank passing through and connected with the reactor cavity. The communicating reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com