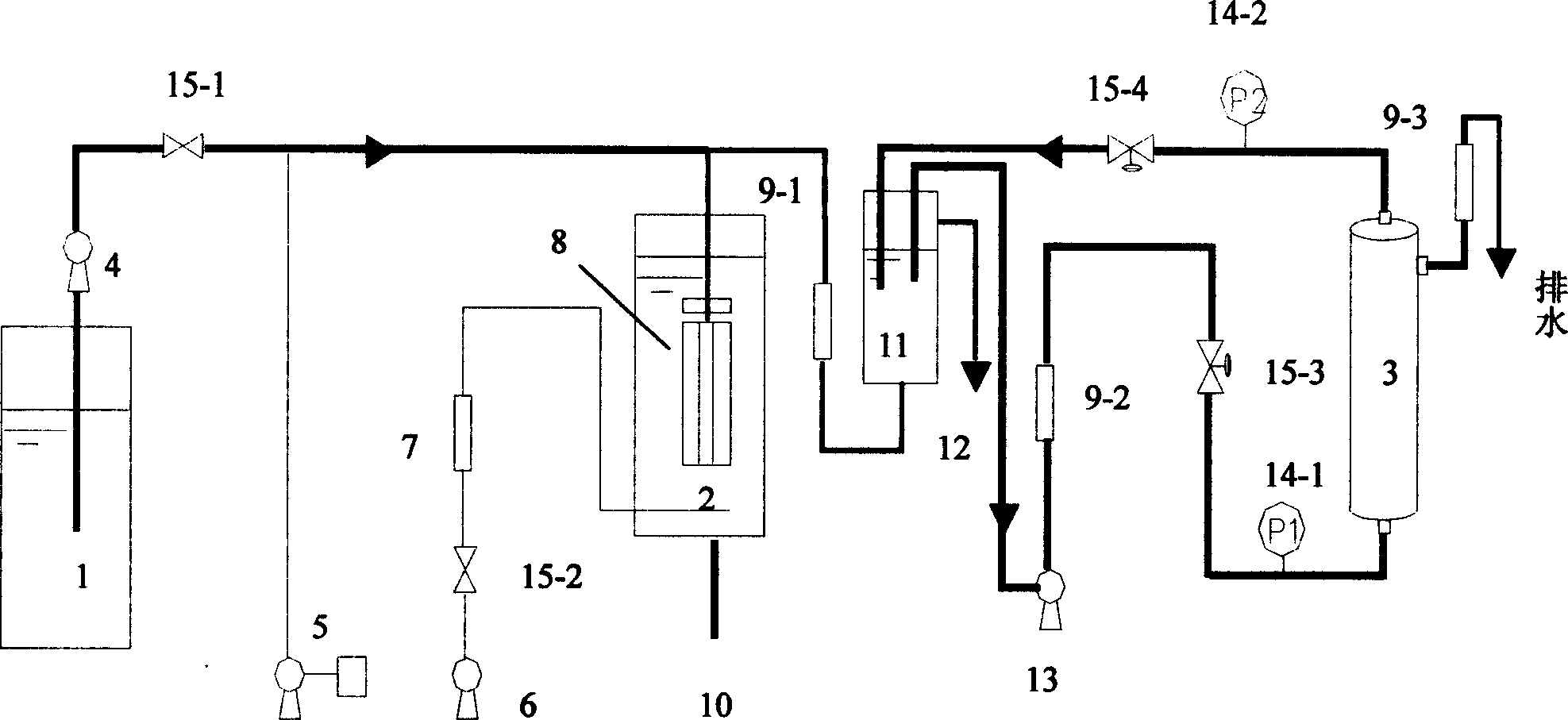

Mine water deeply purifying method and apparatus

A technology for deep purification and mine water, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of large chemical dosage, loose sail structure, strong volatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The experimental device in the accompanying drawings is used, the hollow fiber microfiltration membrane used is polypropylene material, and the membrane area of the module is 1.0m 2 , the roll-type nanofiltration membrane used is polyamide material, and the membrane area of the module is 2.6m 2 .

[0015] Operating conditions: (1) High-suspended mine water is only treated by the CMF reactor, and no longer enters the nanofiltration membrane device. The dosage of polyaluminum chloride is 20ppm, and the suction negative pressure is 0.05MPa. The water quality before and after treatment is shown in Table 1.

[0016] (2) After the high sulfate mine water is treated by the CMF reactor, it enters the nanofiltration membrane device for desalination treatment.

[0017] The dosage of polyaluminum chloride is 10ppm, the suction negative pressure is 0.05MPa, and the operating pressure of nanofiltration membrane is 0.7MPa. The water quality before and after treatment is shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com