Plasma display panel

A display panel and plasma technology, applied in the direction of alternating current plasma display panels, gas discharge electrodes, solid cathode parts, etc., can solve the problems of shortening the life of the plasma display panel 10, and improve luminous efficiency and light emission efficiency, reduce Capacitance, effect of size increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, embodiments of the present invention will be more fully described in conjunction with the accompanying drawings.

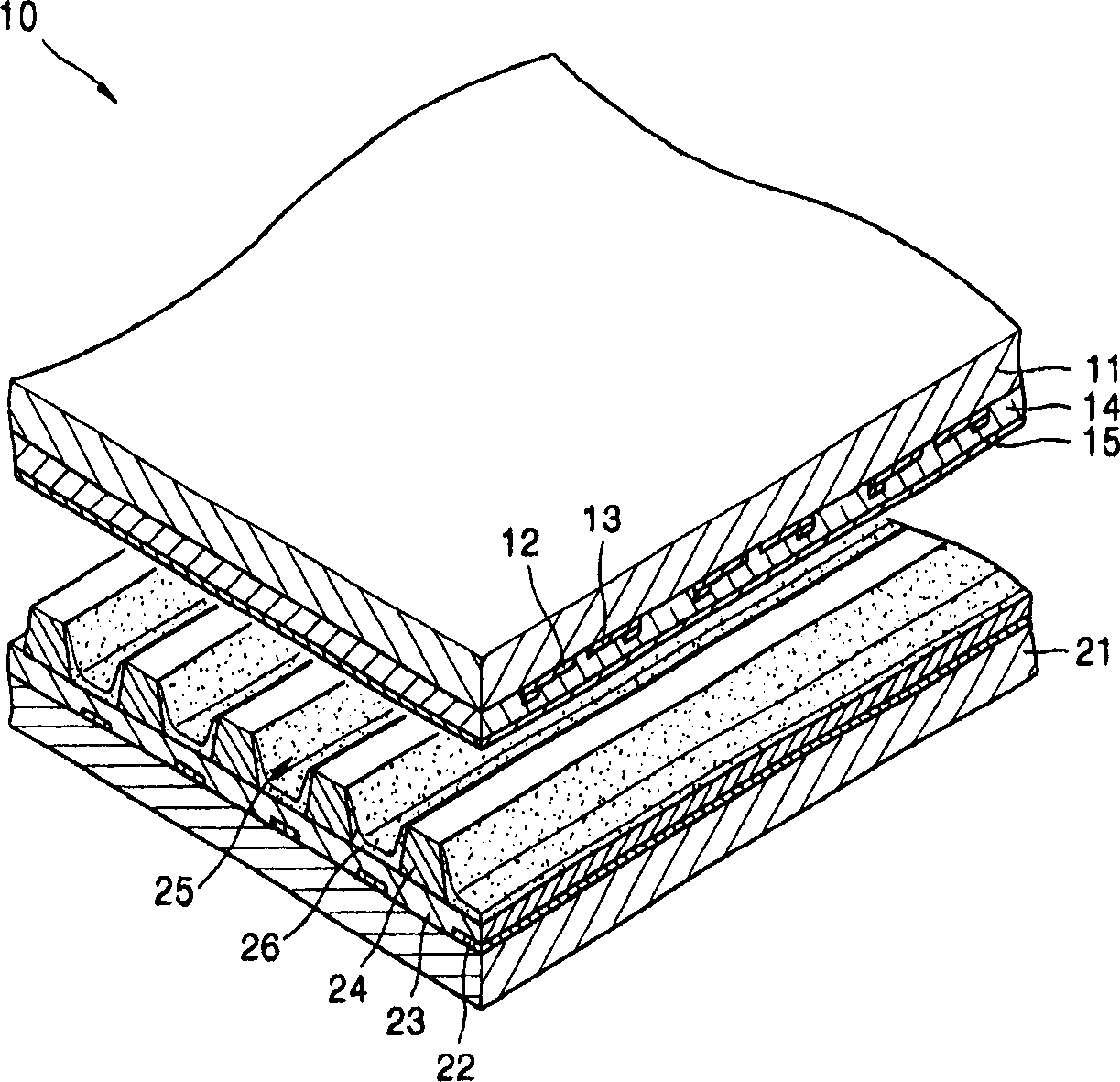

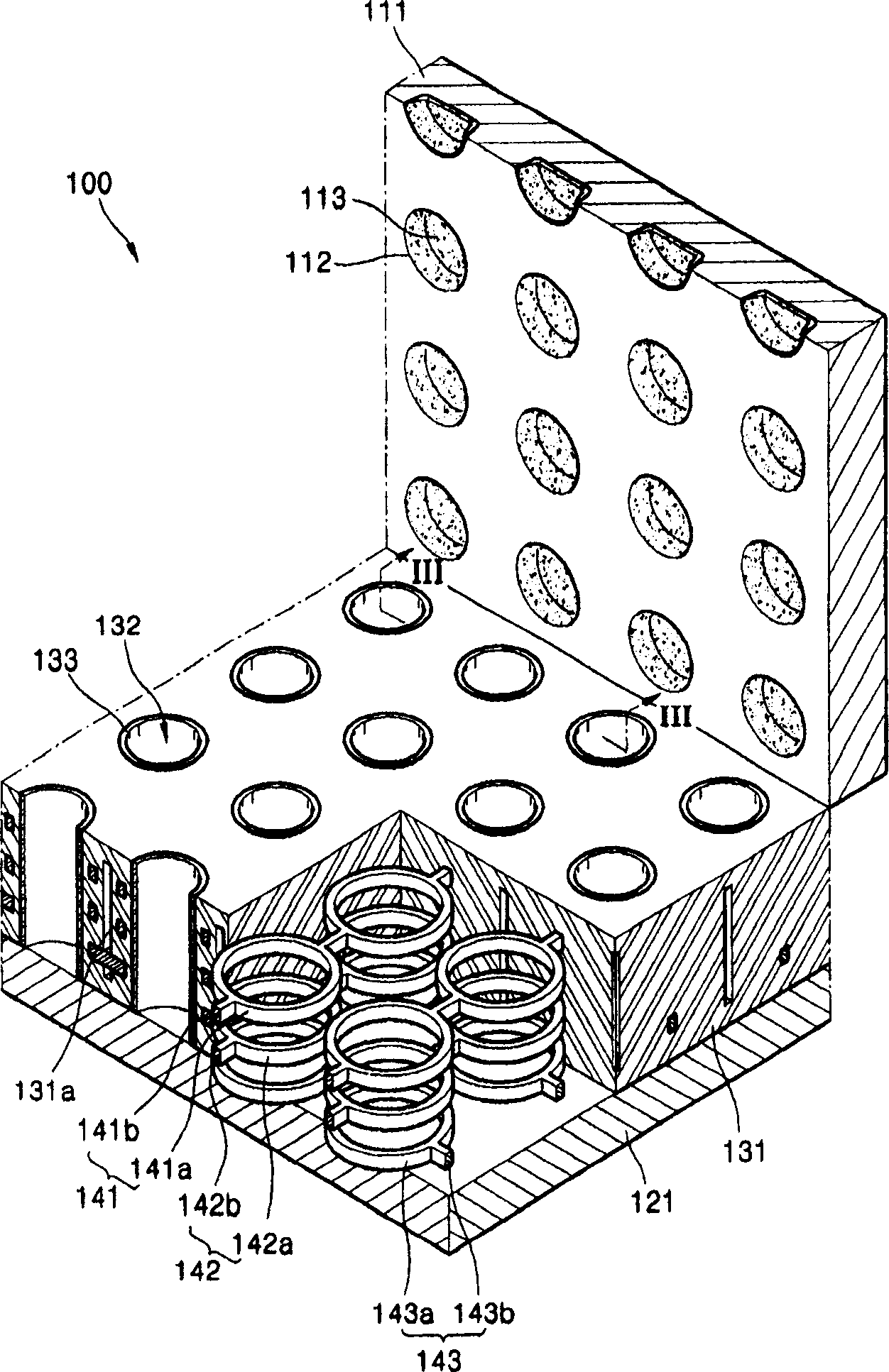

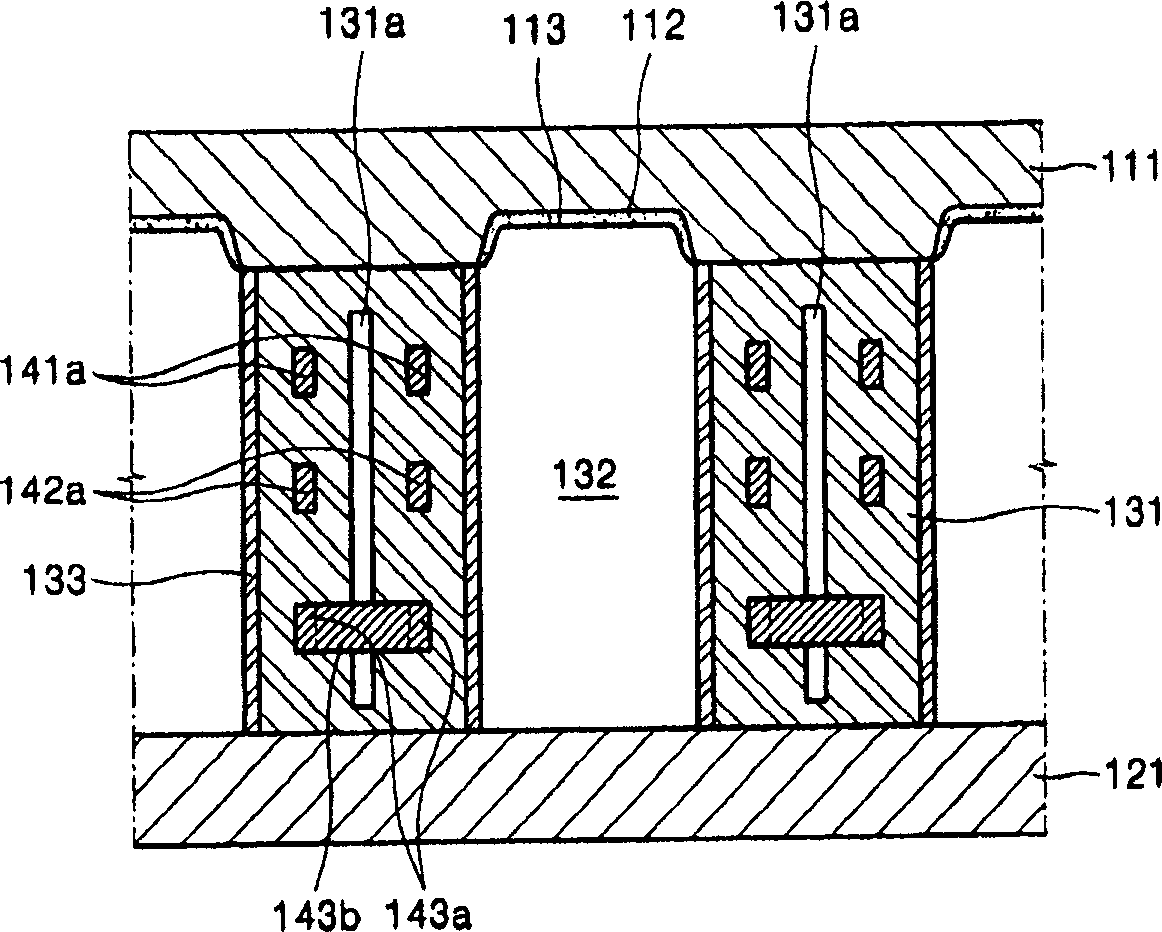

[0047] see figure 2 and image 3 A plasma display panel (PDP) 100 according to one embodiment of the present invention includes an upper substrate 111 and a lower substrate 121 opposite to the upper substrate 111 . An image is displayed onto at least one of the upper substrate 111 and the lower substrate 121 . The substrate on which the image is displayed is made of light-transmissive material.

[0048]The barrier structure 131 is disposed between the upper substrate 111 and the lower substrate 121 . The barrier structure 131 separates a plurality of discharge cells 132 corresponding to sub-pixels and prevents undesired discharge from being generated due to crosstalk between the discharge cells 132 and the like. In one embodiment, the barrier structure 131 may be designed such that the discharge cells 132 have a closed structure. In one em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com