Electrostatic chuck for substrate stage, electrode used for same, and processing system having the chuck and electrode

An electrostatic chuck and processing system technology, applied in the field of processing systems, can solve problems such as low reliability, increased electrode manufacturing cost, and extended product delivery time, and achieve the effects of low price, easy processing, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of an electrostatic chuck for a substrate mounting table, electrodes used therefor, and a processing system including them according to the present invention will be described in detail below with reference to the drawings.

[0019] Plasma treatment device

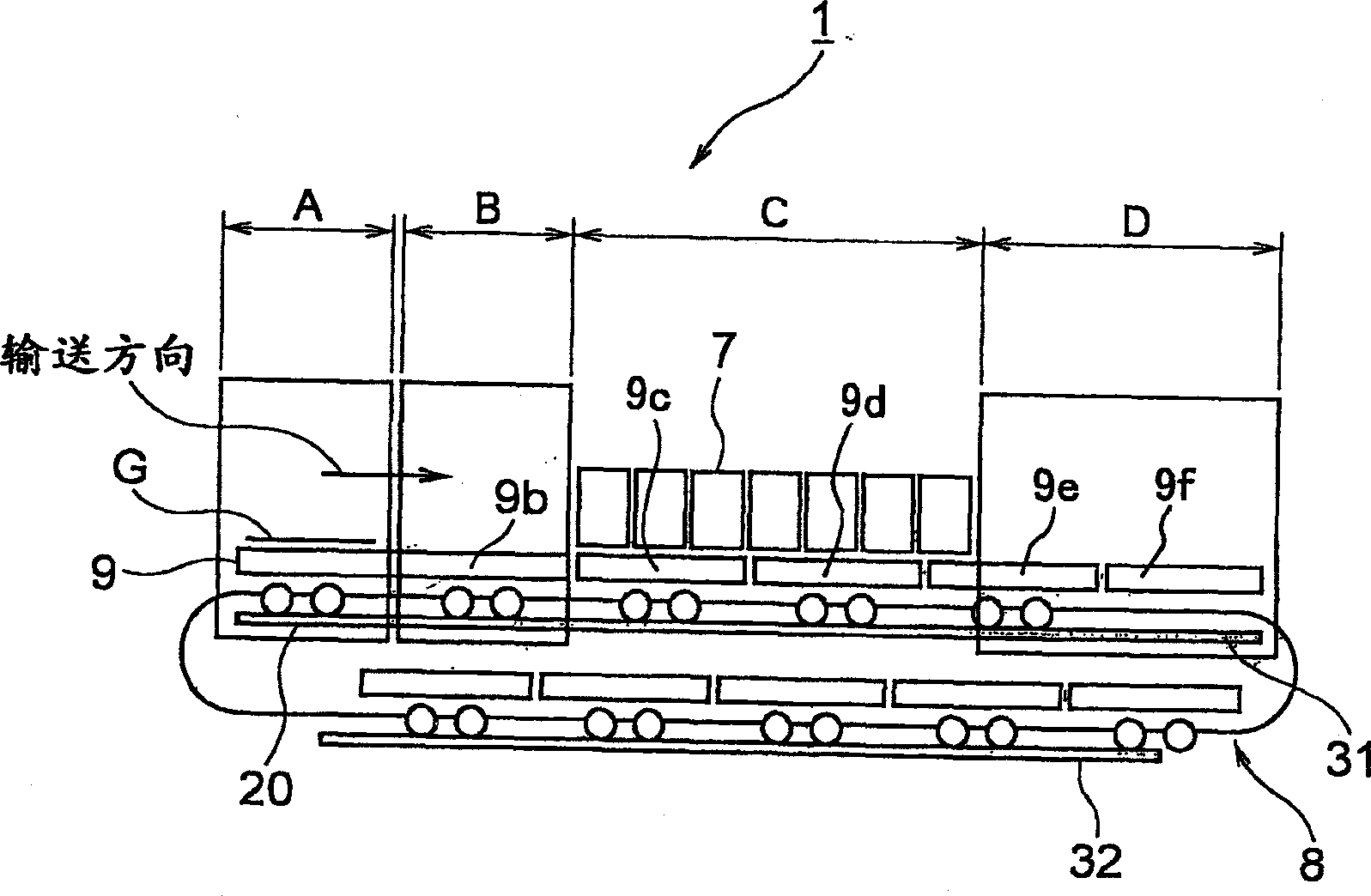

[0020] The plasma processing apparatus 1 using the electrostatic chuck for a substrate mounting table of the present invention is configured to perform continuous transfer processing of a substrate G (for example, a glass substrate), that is, in-line processing. The substrate stage 9 on which the substrate G is placed faces the conveying direction (arrow →) in the substrate transfer / preheating / adsorption zone A with the heating unit 20, the heating zone B, the film formation or The etching zone C and the cooling / release transfer zone D with the cooling unit 31 are sequentially transported to the positions 9b→9c→9d→9e→9f by the circular substrate conveying mechanism 8 with a return loop, while performing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com