Fire extinguisher and extinguishing method for preventing magnesium and magnesium-alloy from burning

A fire extinguishing device and magnesium alloy technology, applied in the field of fire extinguishing, can solve problems such as inability to burn magnesium and magnesium alloy flames, and achieve the effects of simple structure, convenient use, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

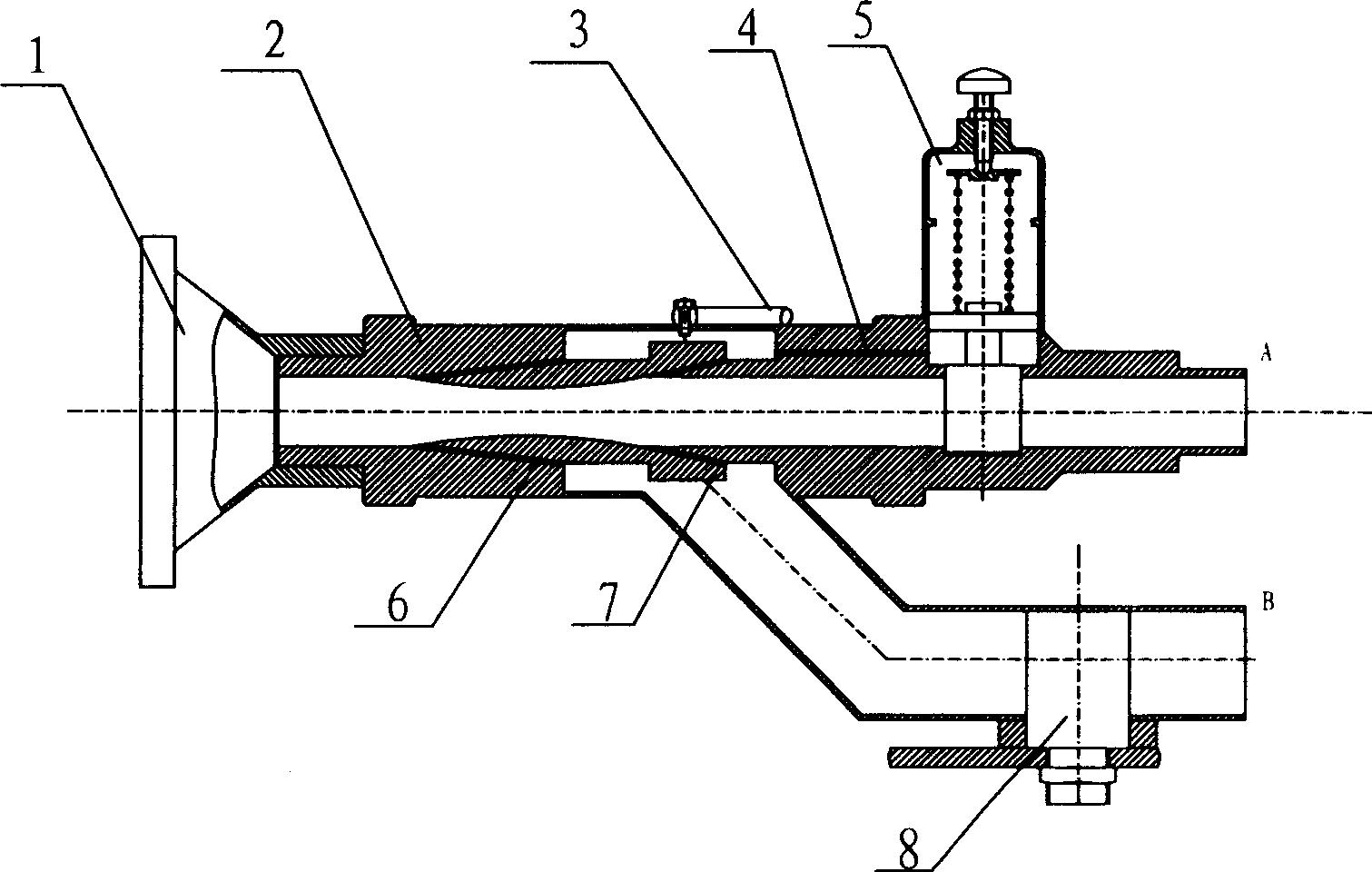

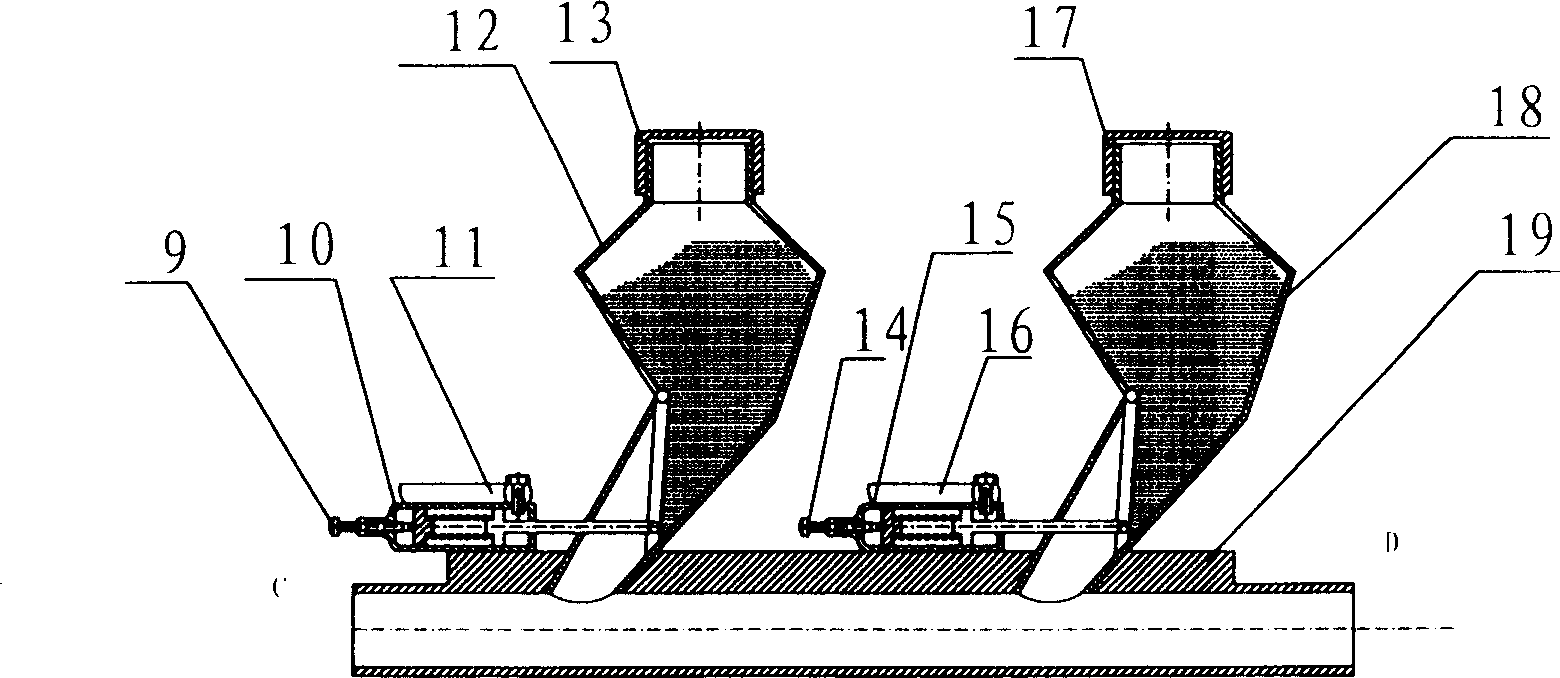

[0019] The fire extinguishing method for preventing magnesium and magnesium alloys from burning in the present invention adopts the method of spraying flux with pressure flame-retardant gas to extinguish fire, wherein the mixing ratio of flux and flame-retardant gas is adjusted as required. The flame-retardant gas is carbon dioxide or argon, and the flux is the No. 2 flux used in aluminum and magnesium smelting in the non-ferrous metal smelting industry. Wherein, the volume ratio of the flame retardant gas to the No. 2 flux is 1-2.5:1, preferably 2:1.

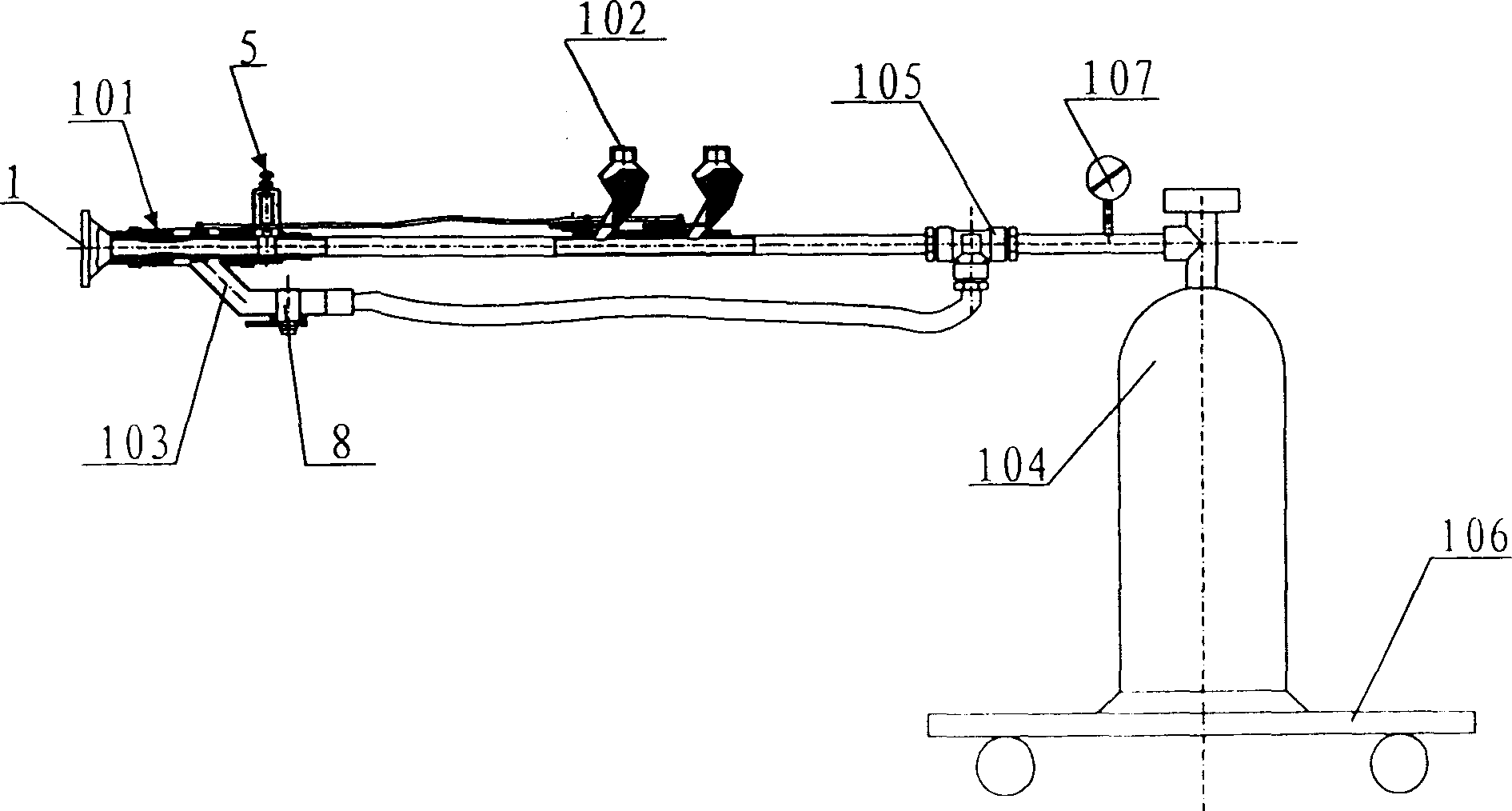

[0020] Such as figure 1 As shown, the fire extinguishing device designed for preventing magnesium and magnesium alloys from burning according to the method of the present invention is made up of a spray gun 101, a powder supply device 102, a high-pressure gas bottle 104 and a communication pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com