Making-up wooden plate

A splicing, plate technology, which is applied in the direction of wood processing appliances, wood veneer joining, manufacturing tools, etc., can solve the problems of high product cost, easy detachment, large gap, etc., to achieve compact structure, simple processing, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

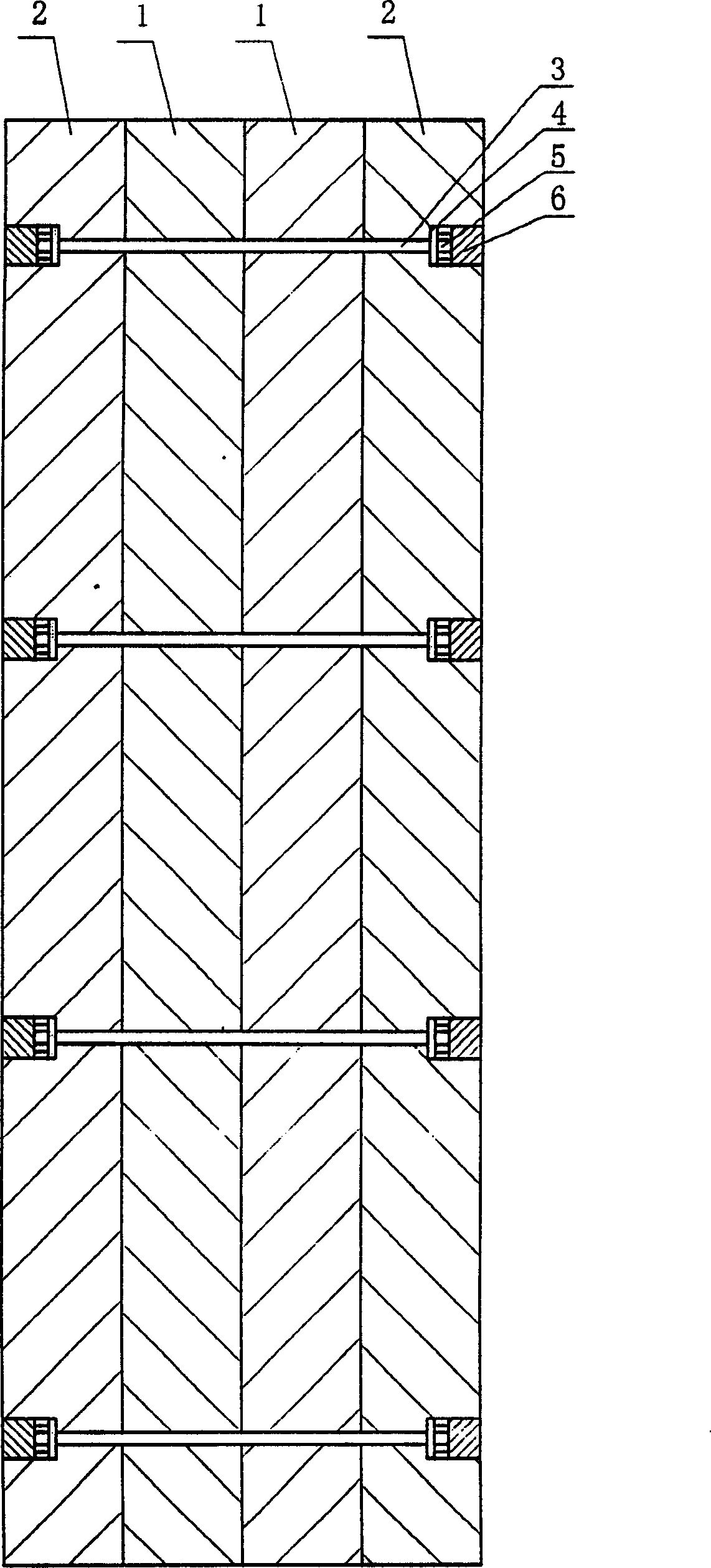

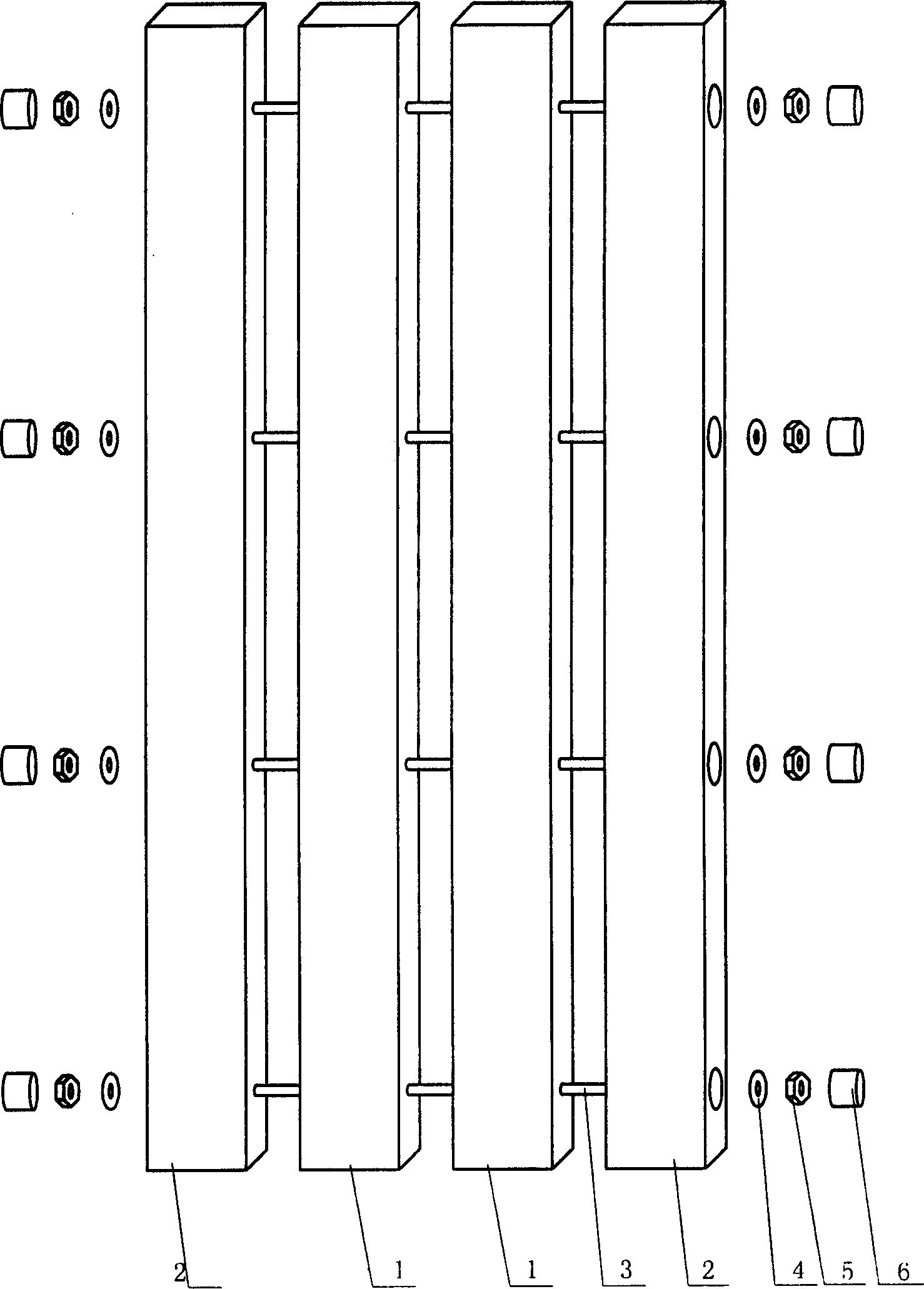

[0014] see Figure 1 ~ Figure 3 , the present invention is composed of a strip plate and a connector, and a plurality of parallel strip plates are fastened and connected by the connector to form a flat plate.

[0015] Wherein: the strip plate includes an inner plate 1 and a side plate 2, the number of the inner plate 1 is determined by the size of the required plate, and there are two side plates 2 on its two edges. In the middle of the thickness direction of each inner plate 1 and side plate 2, a plurality of through holes are spaced apart along the length direction, and a sinker concentric with the through hole and larger in diameter than the through hole is opened at the outer end of the side plate 2. hole.

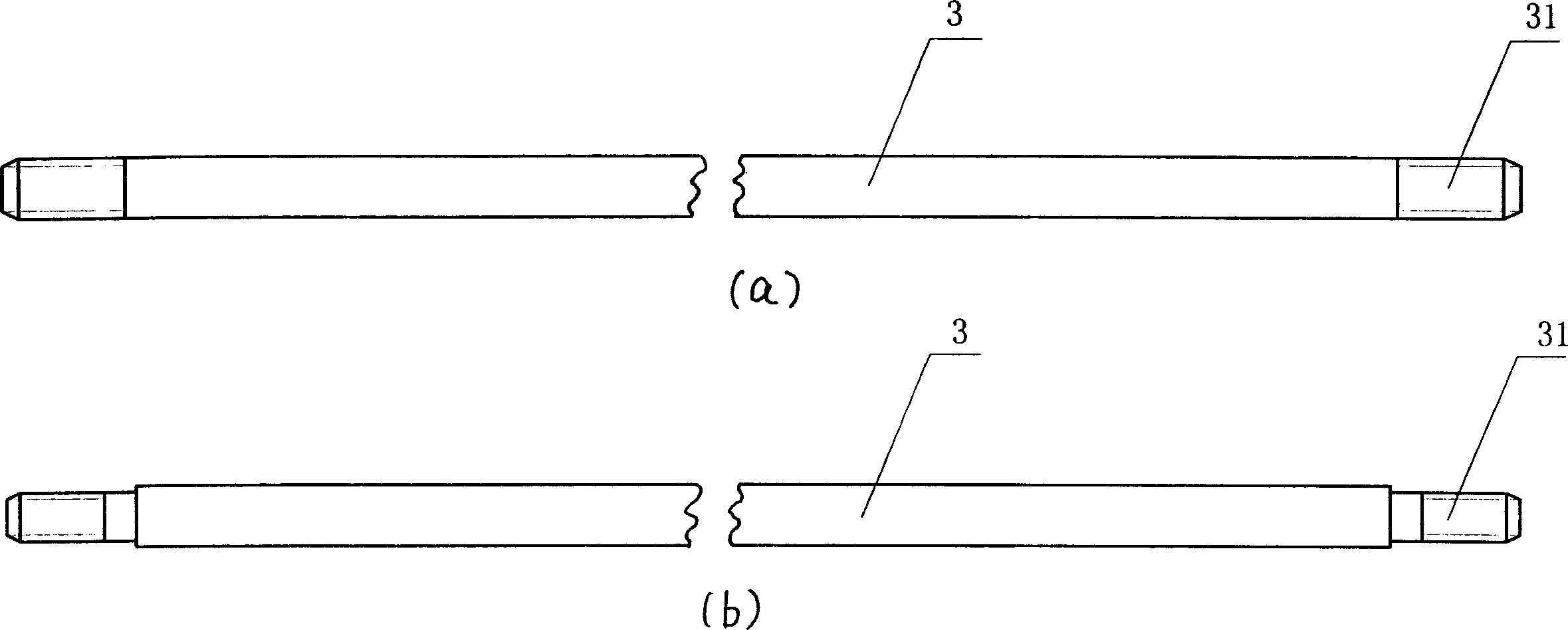

[0016] Described link comprises connecting rod 3, gasket 4, nut 5 and cork 6, is provided with screw thread 31 at the two ends of connecting rod 3, image 3 (a) The thread 31 is equal in diameter to the rod body of the unthreaded part; image 3 The outer diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com