Double-efficient energy-saving methanol rectifying apparatus and method

A double-effect rectification and methanol technology, applied in the field of rectification, can solve the problems of complicated pipelines, space occupation, waste of space at the bottom of the tower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

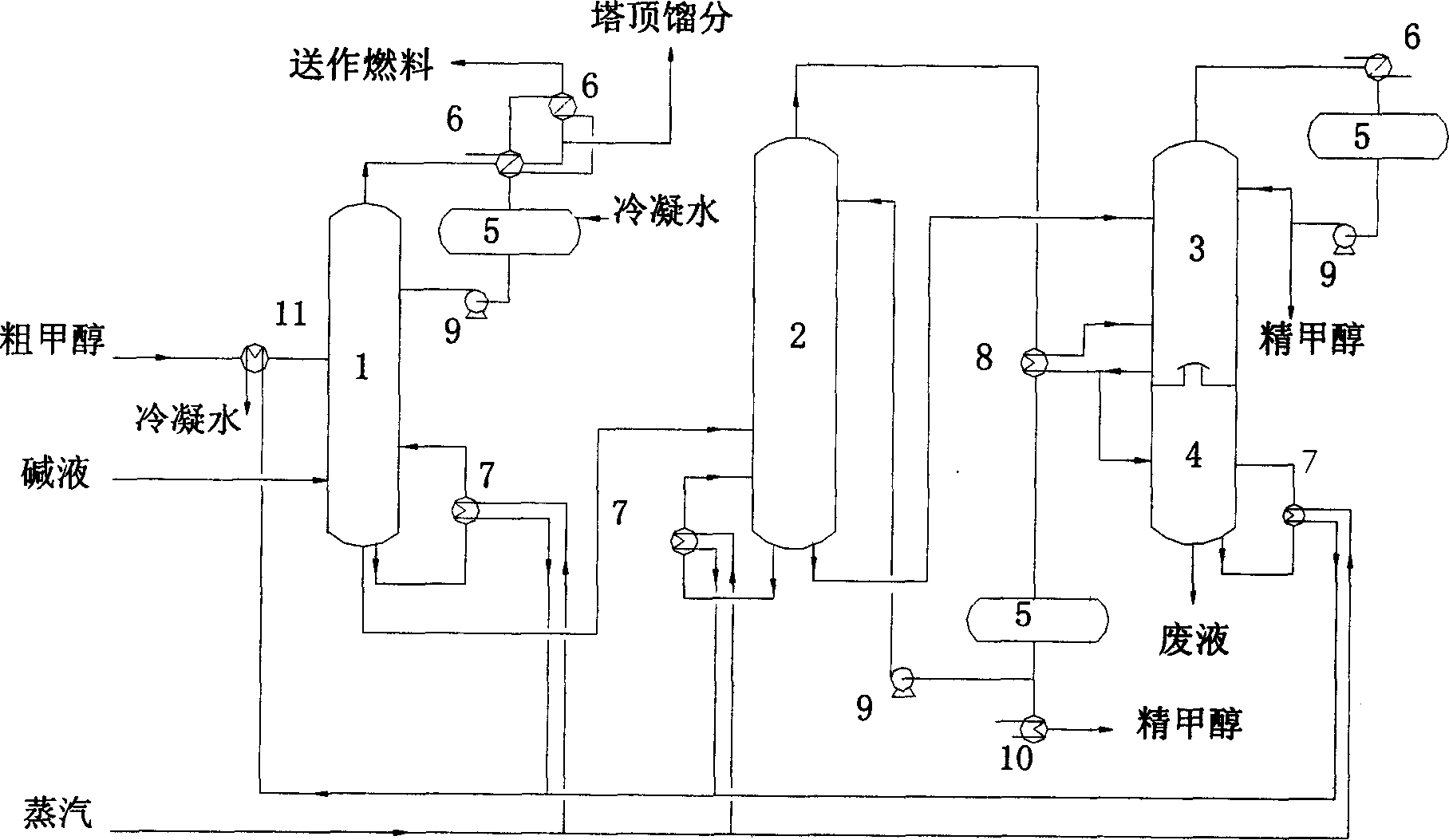

[0024] Attached below figure 1 The device and method of the present invention are further explained, and the specific process is as follows figure 1 Shown. The present invention is mainly composed of a crude methanol preheater 11, a pre-rectification tower 1, a pressurized tower 2, an atmospheric tower 3, a methanol recovery tower 4, a condenser 6, a reboiler 7 and a heat exchange reboiler 8. The atmospheric tower 3 and the methanol recovery tower 4 are connected as a whole structure, and the two are connected by a gas lift cap; the steam condensate pipes in the respective reboilers 7 of the pre-distillation tower 1, the pressurization tower 2 and the methanol recovery tower 4 are all connected to the crude methanol The preheater 11 is connected; the bottom discharge pipe of the pressurizing tower is connected with the middle feed pipe of the methanol recovery tower.

[0025] 1. After the heat exchange of the preheater 11, the crude methanol enters the middle and upper part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com