Pressure-sensitive performance testing method of pressure-sensitive cement-base materials

A technology of cement-based materials and testing methods, which is applied in the measurement of property force of piezoelectric resistance materials, material resistance, material inspection products, etc., can solve the problems of complicated production, expensive testing electrodes, low durability and accuracy question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

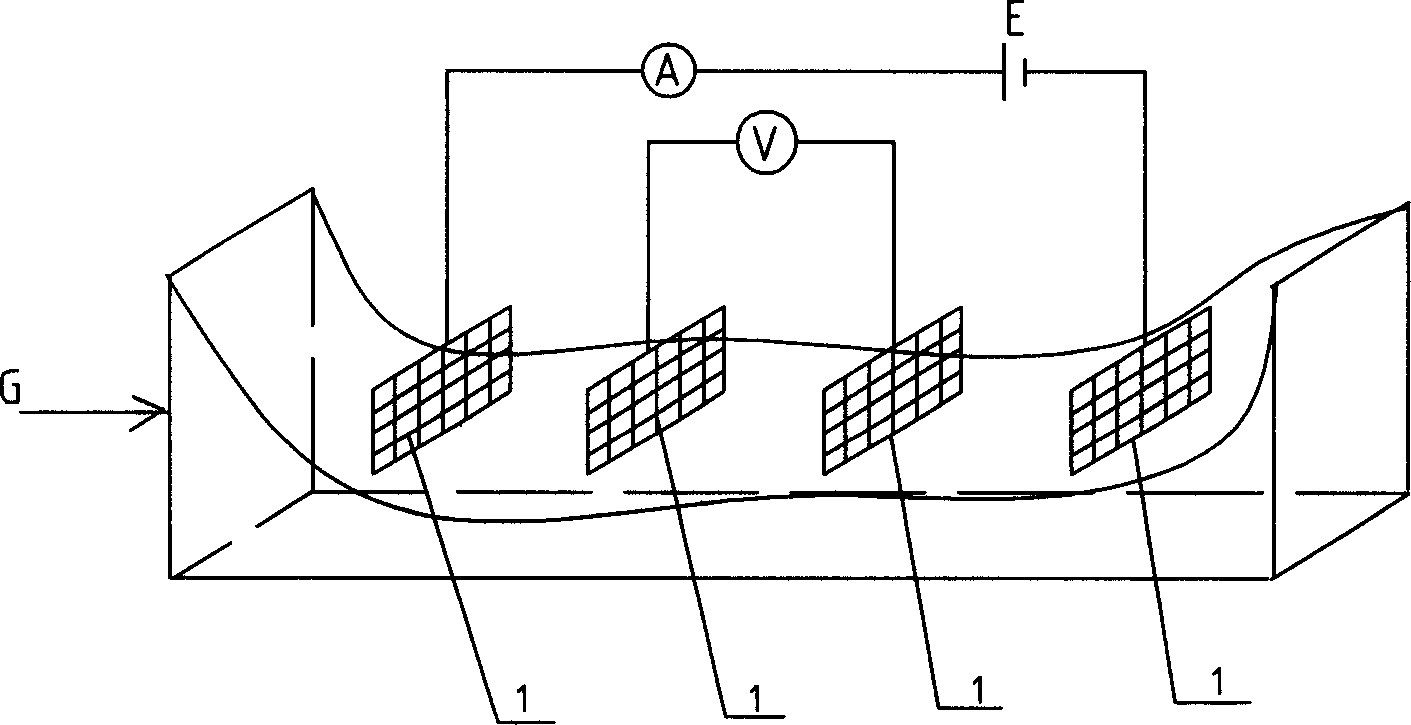

[0006] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. This embodiment is realized through the following steps: 1. Set four mesh metal electrodes 1 in parallel with each other, embed the four mesh metal electrodes 1 with pressure-sensitive cement-based materials and solidify into a whole, and every two mesh metal electrodes 1 There is a pressure-sensitive cement-based material in the middle interval; 2. Apply a DC voltage E between the two mesh metal electrodes 1 located on the outside, and measure and calculate the first resistance R1 between the two mesh metal electrodes 1 located on the inside; 3. 1. Apply pressure G in a direction perpendicular to the four mesh metal electrodes 1; 4. Measure and calculate the second resistance R2 of the pressure-sensitive cement-based material between the two mesh metal electrodes 1 located on the inner side; 5. Determine the pressure G The relationship with the resistan...

specific Embodiment approach 2

[0007] Specific implementation mode two: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that in step 2, a DC voltage E is applied between the two mesh metal electrodes 1 on the outside and the current I1 in the pressure-sensitive cement-based material between the two is measured. The voltage U1 between the two mesh metal electrodes 1 on the inside; calculate the first resistance R1 of the pressure-sensitive cement-based material between the two mesh metal electrodes 1 on the inside, R1=U1 / I1; in step 4, measure The current I2 in the pressure-sensitive cement-based material between two mesh metal electrodes 1, and the voltage U2 between the two mesh metal electrodes 1 on the inner side are measured at the same time, and the pressure-sensitive cement between the two mesh metal electrodes 1 on the inner side is calculated. The second resistor R2 of the base material; other steps are th...

specific Embodiment approach 3

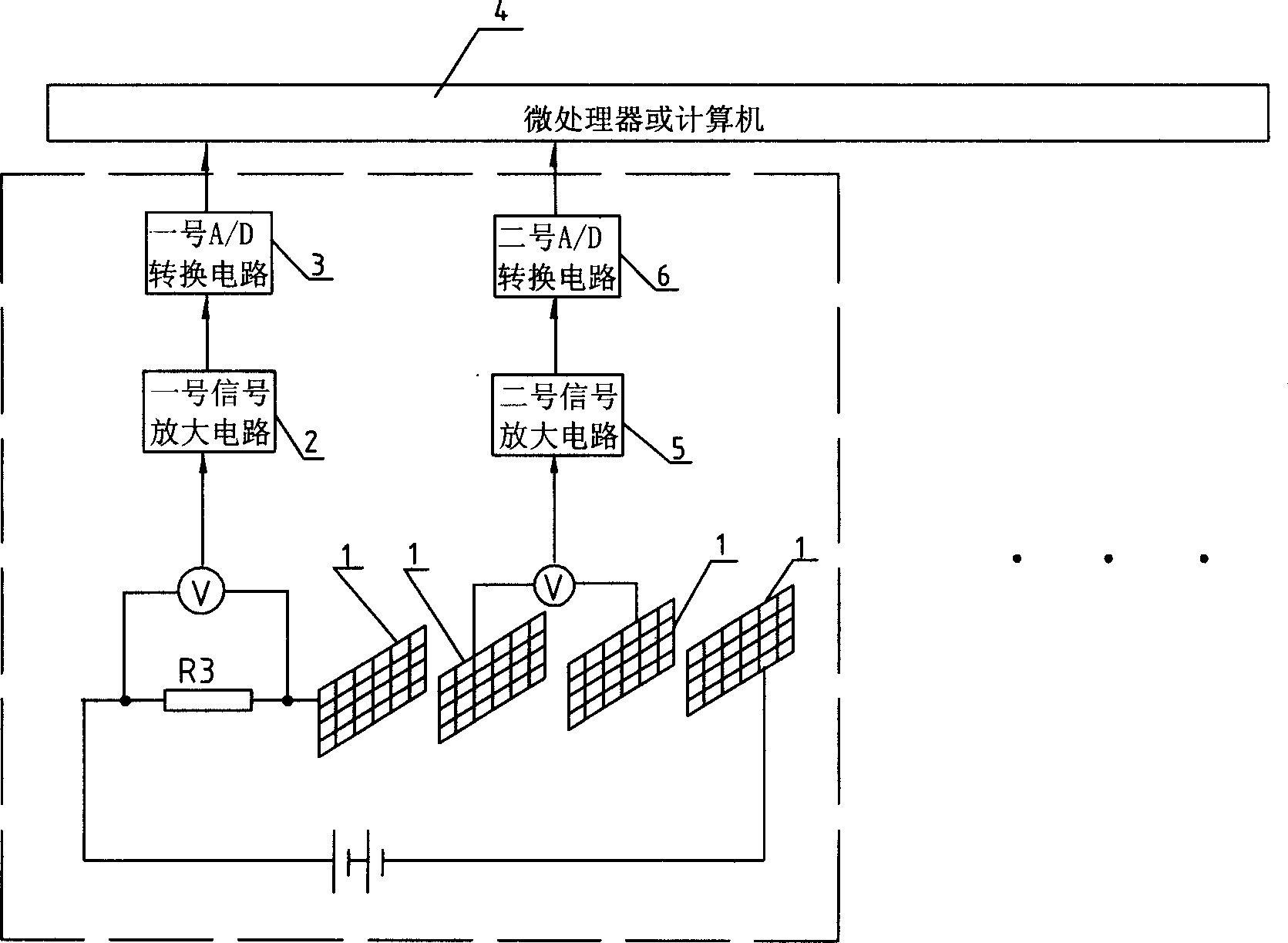

[0008] Specific implementation mode three: the following combination figure 2 This embodiment will be specifically described. The difference between this embodiment and Embodiment 2 is that in step 2, a DC voltage is applied between the standard reference resistor R3 and the two mesh metal electrodes 1 on the outside that form a series circuit with the standard reference resistor R3, extracting The voltage U3 at both ends of the standard reference resistor R3 is processed by the No. 1 signal amplification circuit 2 and the No. 1 A / D conversion circuit 3, and then input into the microprocessor or computer 4, and the two nets located on the inner side are simultaneously extracted. The voltage U4 between the shape metal electrodes 1 is processed by the No. 2 signal amplifying circuit 5 and the No. 2 A / D conversion circuit 6, and then input into the microprocessor or computer 4 to calculate the The first resistor R1 of the pressure-sensitive cement-based material between electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com