Intelligent controlling system of pure water drinker

An intelligent control system, the technology of pure water machine, applied in general control system, control/regulation system, computer control and other directions, can solve the problems of slow response speed, low control accuracy, low equipment desalination rate, etc., to achieve convenient self-maintenance, High control precision and accurate display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

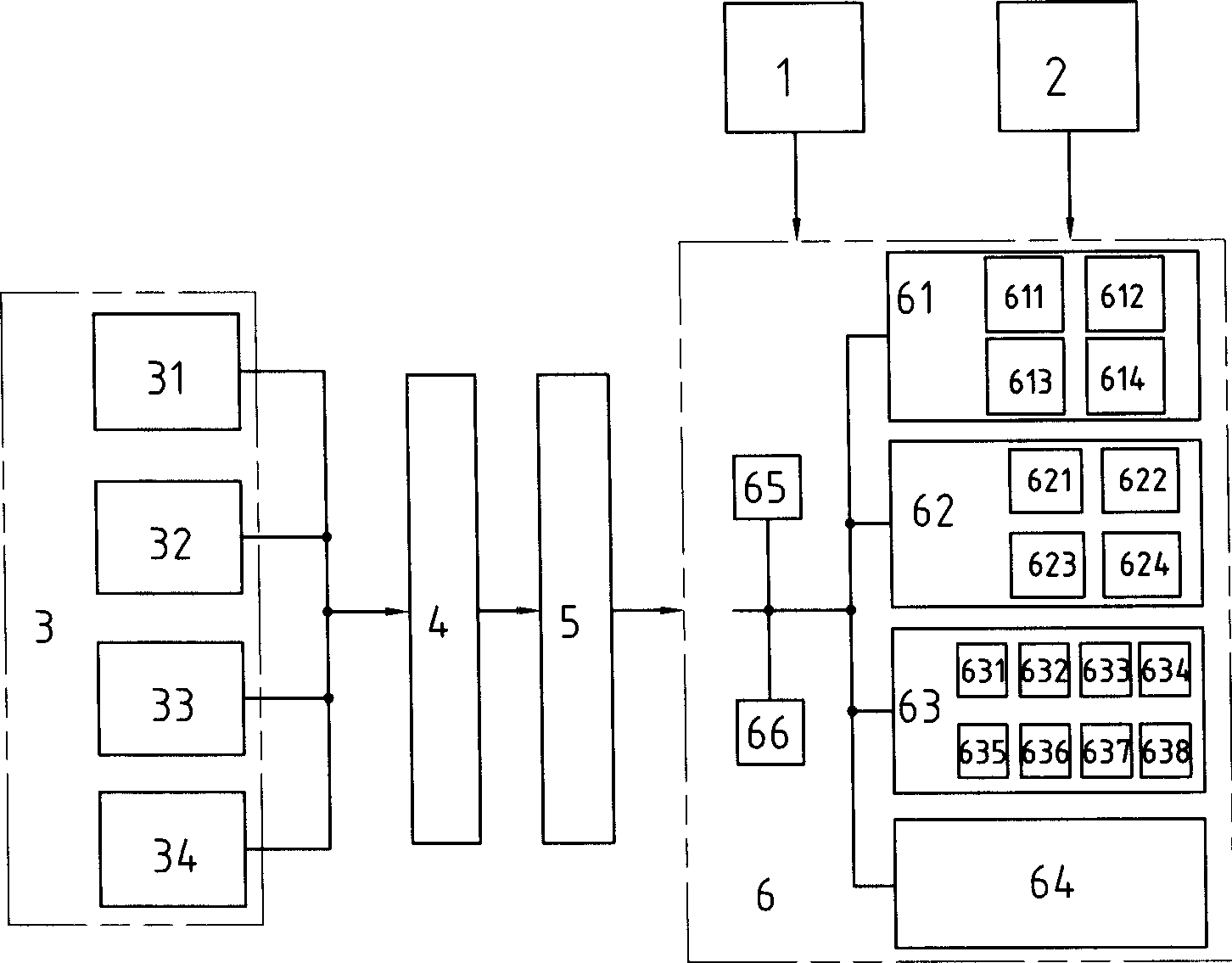

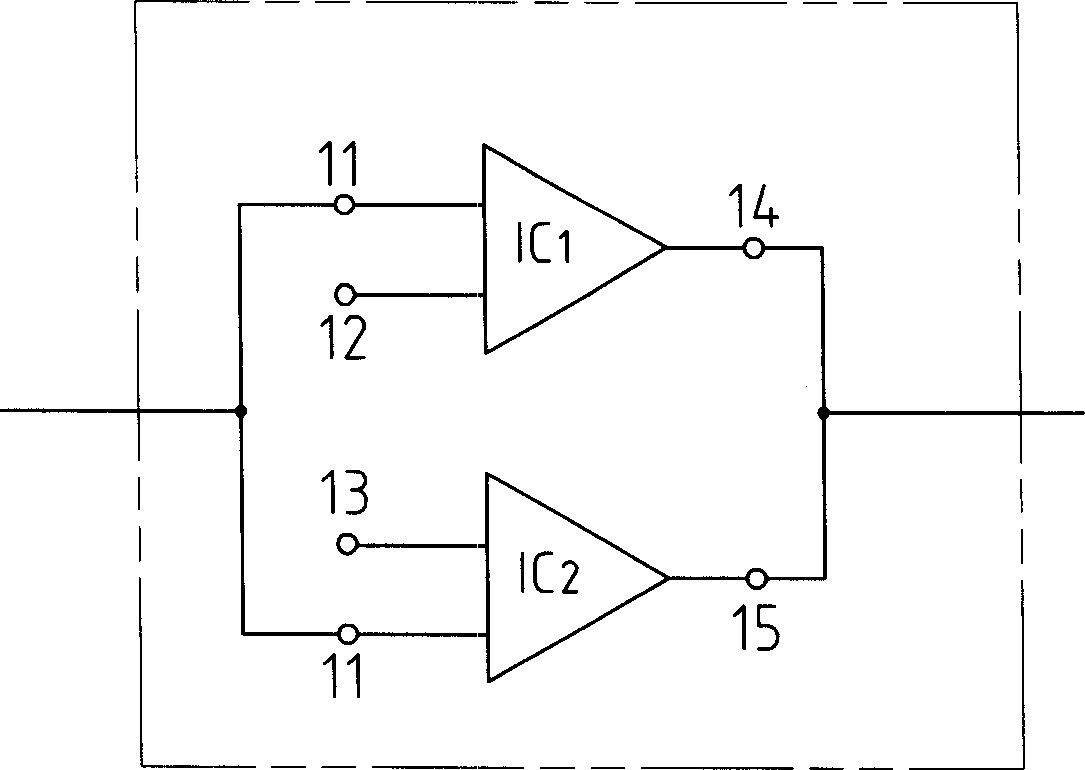

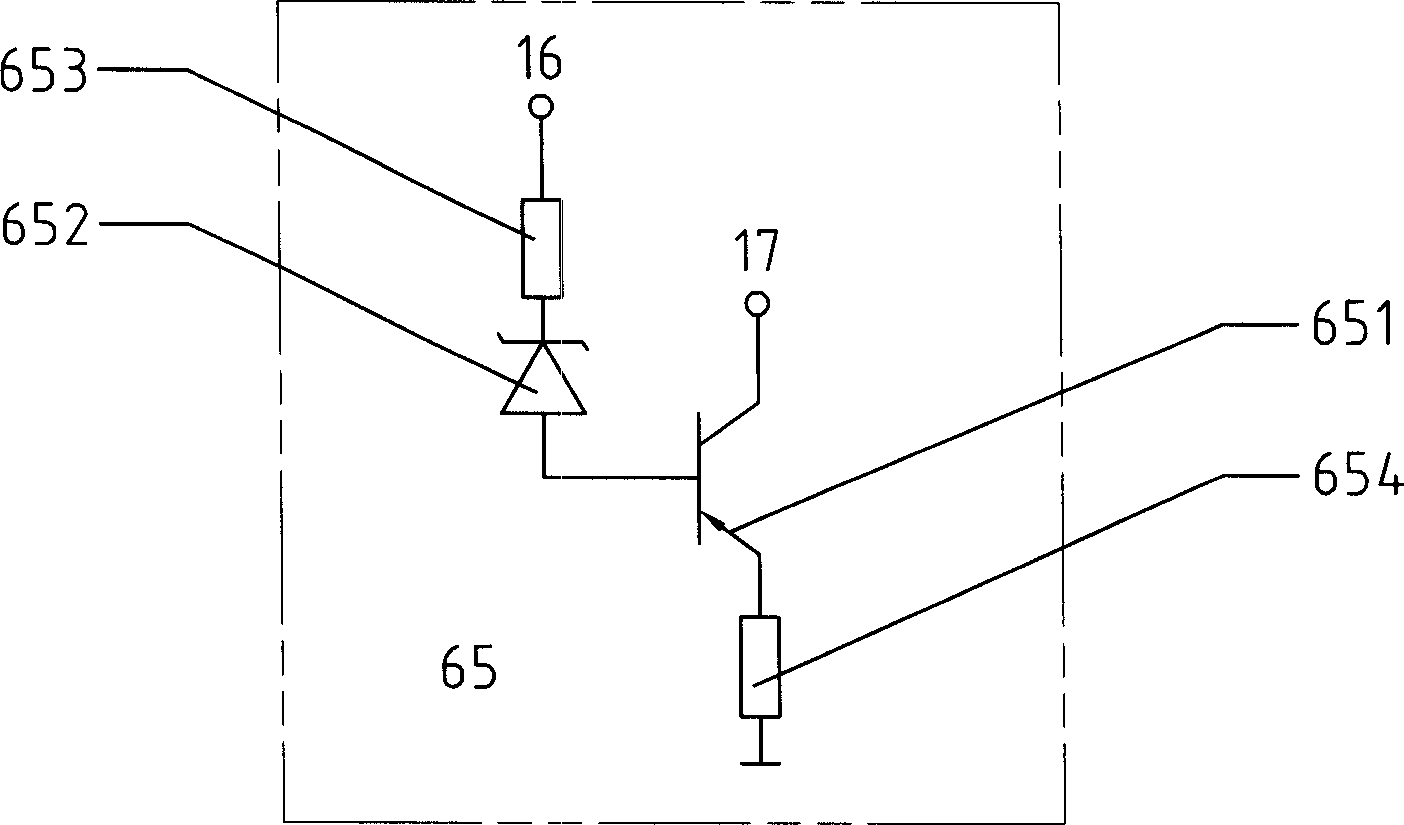

[0022] according to figure 1 As shown, the intelligent control system for pure water machine of the present invention includes a sensor module 3, a signal processing module 4, a signal monitoring module 5 and a control center 6 electrically connected in sequence, wherein the control center 6 is also connected to the external power supply unit 1 respectively. It is connected with the forced flushing button unit 2. The reverse osmosis membrane can be cleaned by forcibly flushing the key unit 2 . The sensor module 3 consists of a tap water pressure sensor 31 placed in the external water pipe, a pre-membrane pressure sensor 32 located on the side of the tap water cavity of the reverse osmosis membrane, a pressure barrel pressure sensor 34 built in front of the pressure barrel, and a pure water quality sensor. 34. Among them, the pure water quality sensor 34 is built in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com