Source driver and its driving method

A source driver and source driver technology, applied in the direction of instruments, static indicators, etc., can solve the problems of not being able to reach the full range of VSS~VDD, difficult Vout pull-down, etc., to achieve size reduction, circuit manufacturing cost reduction, and reduce the number of uses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

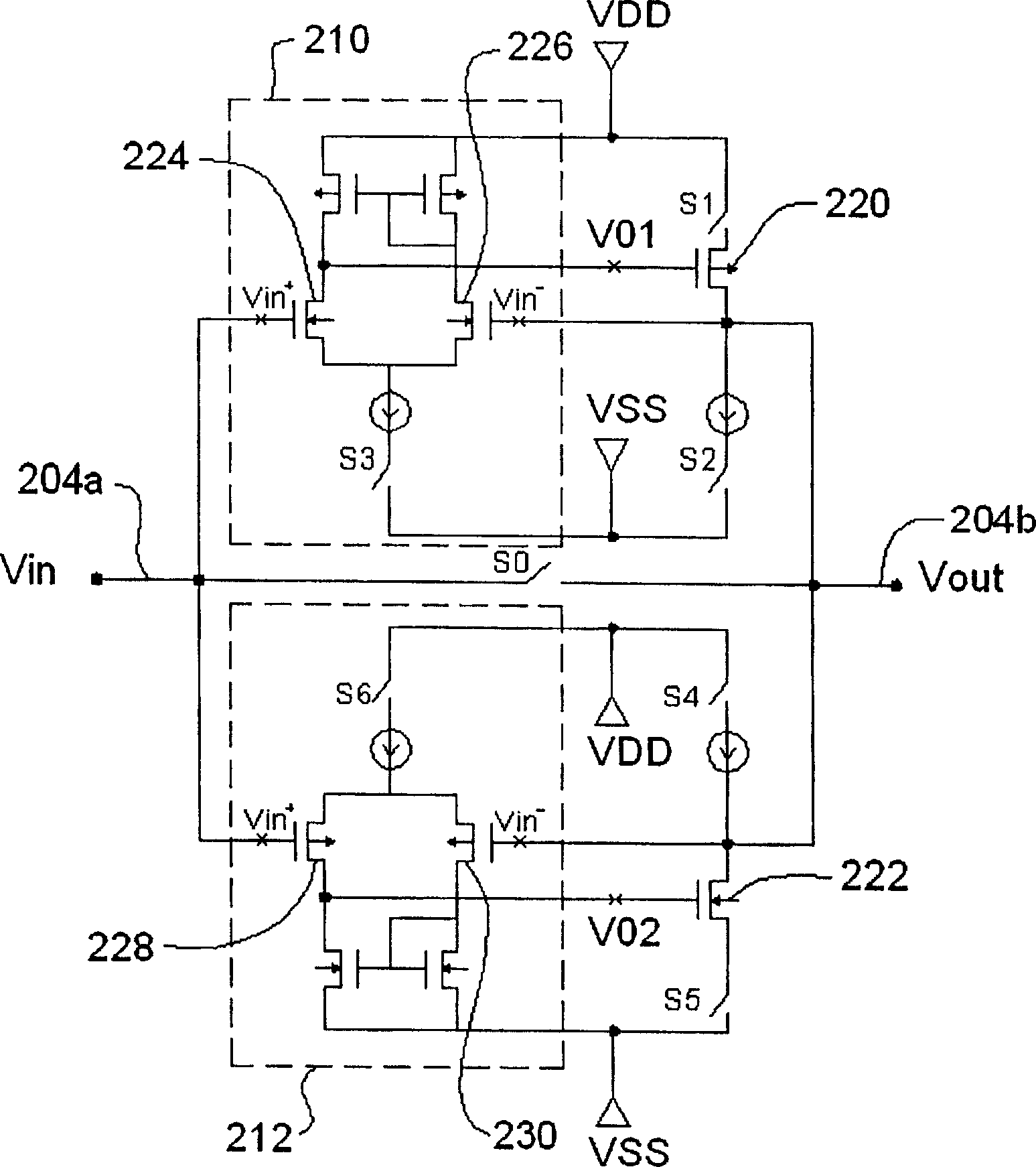

[0064] Please refer now Figure 4 , which shows a circuit block diagram of a source driver 300 of a liquid crystal display according to an embodiment of the present invention. The source driver 300 has two input terminals 300a, 300b for respectively receiving level voltage levels Vin1, Vin2 from a voltage divider (such as the voltage divider 200 shown in FIG. 2 ), and two output terminals 300c, 300d for Individually electrically connected to two data lines (such as the data line 116 shown in FIG. 1 ) of a liquid crystal panel, wherein the two output terminals 300c, 300d respectively have output voltage levels Vout1, Vout2. The source driver 300 includes a pull-up (pull high) differential amplifier 302, a pull-down (pull low) differential amplifier 304, a voltage clamping (clamp) circuit 306, a first switch circuit 308, a second switch circuit 310 and a third switch circuit 312 . The first switch circuit 308 has switches S1 , S2 , S3 and S4 ; the second switch circuit 310 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com