Fluidized bed reactor used for Fischer-Tropsch synthesis

A fluidized bed reactor, Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, hydrocarbon production from carbon oxides, chemical/physical processes, etc. Short average life, large heat release and other problems, to achieve the effect of easy control of operating parameters, reliable industrial operation, and reduced probability of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

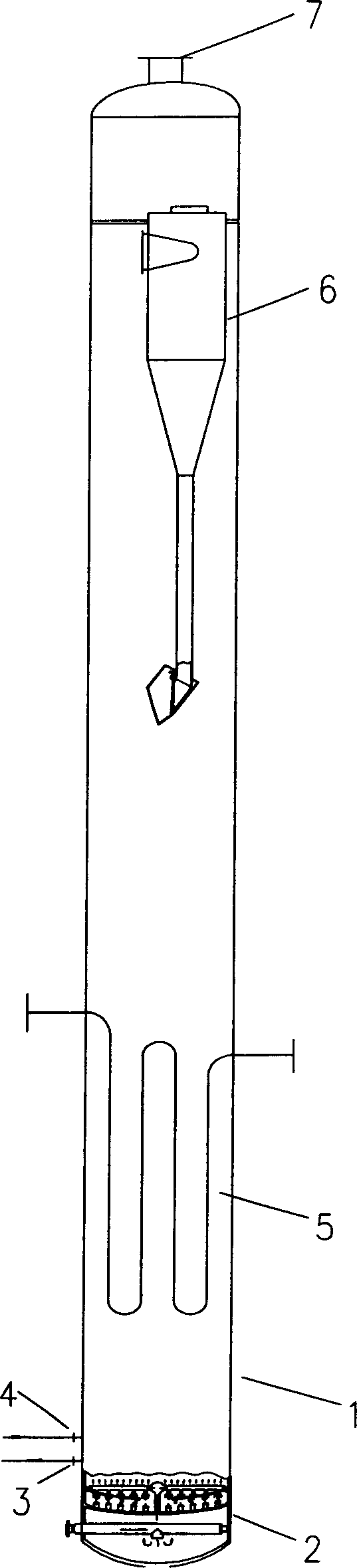

[0028] The following example is an example of a fluidized bed reactor for a Fischer-Tropsch synthesis process. to combine Figure 1 ~ Figure 4 Be explained.

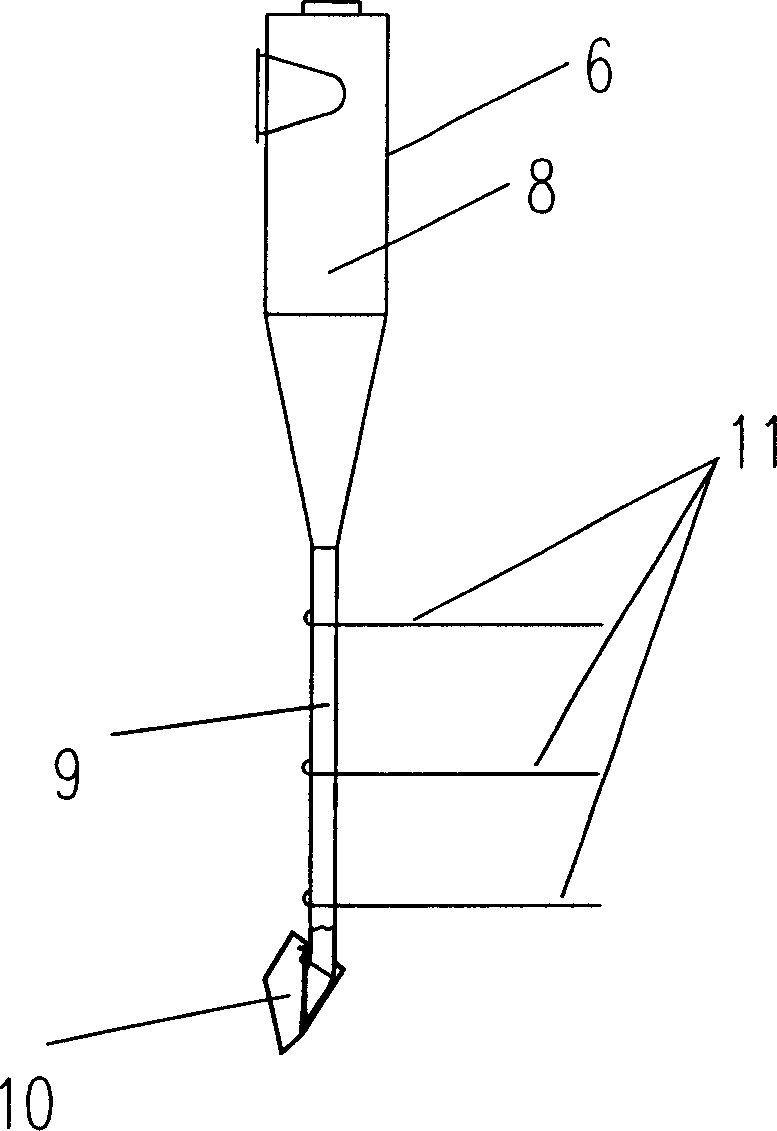

[0029] like figure 1 , the synthesis reactor 1 includes a layer of heat exchange tubes 5 and a cyclone separator 6 .

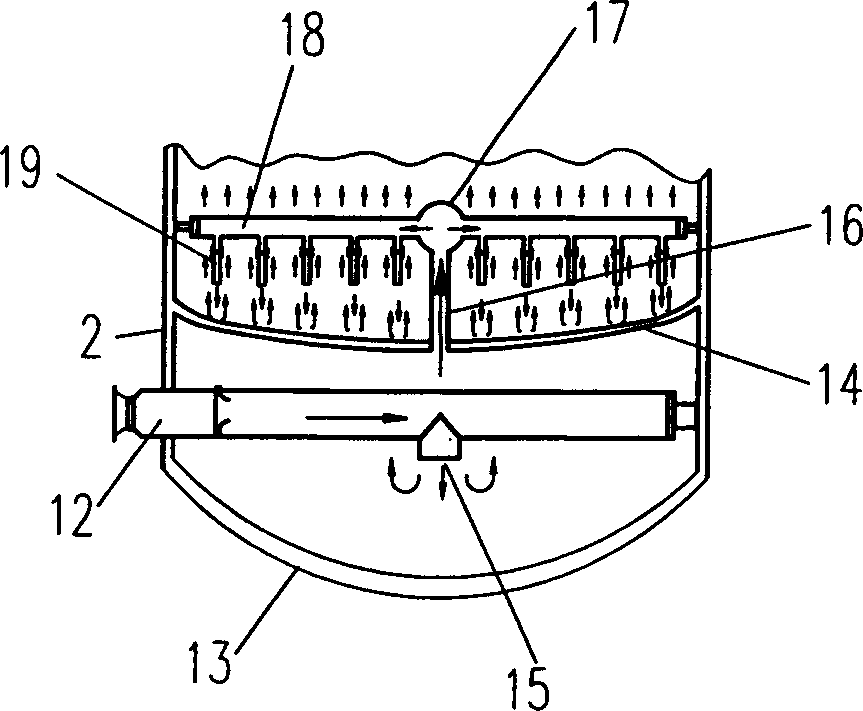

[0030] The synthesis gas is distributed to the gas from the gas inlet distributor 2, and the size and number of the designed nozzles ensure that the pressure drop of the gas passing through the gas inlet distributor 2 is not less than 0.3 bar, so that the gas can enter the fluidized bed evenly .

[0031] Upward from the gas inlet distributor 2 is a heat exchange tube 5, which is a circuitous multi-pass heat exchange tube. The Fischer-Tropsch synthesis reaction is an exothermic reaction. The boiler feed water is passed through the heat exchange tube 5, and the reaction heat is taken away by the evaporation of the boiler feed water, so that the reaction is in a constant temperature state. When the dev...

Embodiment 2

[0045] The following example is an example of a porous metal filter in a fluidized bed reactor for gas-solid separation in a Fischer-Tropsch synthesis process. to combine Figure 4 Be explained. Reactor operating conditions, catalyst particle size and structure are the same as in Example 1, except that the cyclone separator is replaced by a porous metal filter.

[0046] like Figure 4As shown, the porous metal filter 20 in this example is composed of a metal sintered filter element and placed in the dilute phase region of the reactor. The material of the filter element used is 316SS, the size is φ50×800, the specification is 3μm, and there are 24 pieces. The gas is first filtered through the porous metal filter 20, and the filtered gas enters the gas collection chamber 22 through the connecting pipe on the suspension flange 21 and then exits the reactor.

[0047] The implementation effect of the filter described in this embodiment is as follows:

[0048] Continuous operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com