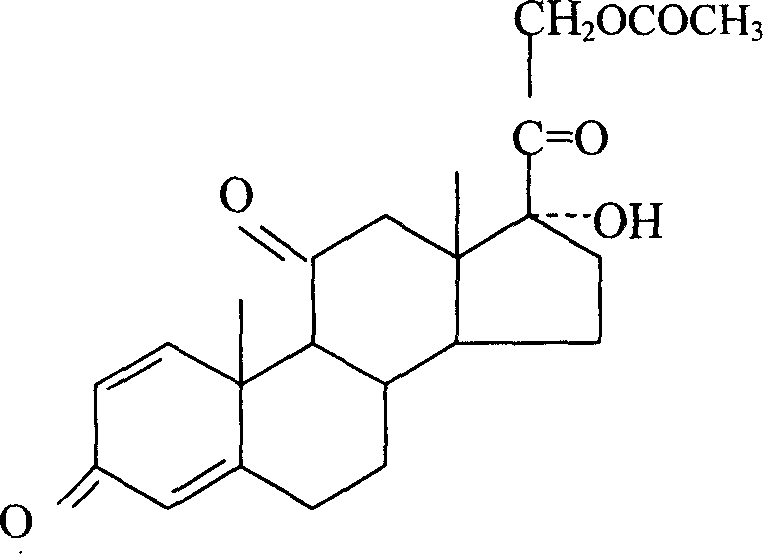

Production method of prednisone hydrolysate

A production process and hydrolyzate technology, applied in the direction of steroids, organic chemistry, etc., can solve the problems of low quality and yield of reactants, large amount of solvent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0012] Throw in 60g of raw materials, 600-650ml of chloroform methanol (specific gravity 1.10-1.15), dissolve and clear, add 4-6% potassium hydroxide / methanol as a catalyst, react at 0-5°C for 30 minutes, neutralize and concentrate after the reaction is complete Crystallized, cooled, filtered, and dried to obtain 50 g of prednisone hydrolyzate, the liquid phase detection content was 97.8%, and the yield was 83.3%.

Embodiment approach 2

[0014] Throw in 60g of raw materials, 600-650ml of chloroform methanol (specific gravity 1.10-1.15), dissolve and clear, add 4-6% potassium hydroxide / methanol as a catalyst, react at 0-5°C for 30 minutes, neutralize and concentrate after the reaction is complete Crystallized, cooled, filtered, and dried to obtain 50.2 g of prednisone hydrolyzate, the liquid phase detection content was 98.2%, and the yield was 83.7%.

Embodiment approach 3

[0016] Throw in 60g of raw materials, 600-650ml of chloroform methanol (specific gravity 1.10-1.15), dissolve and clear, add 4-6% potassium hydroxide / methanol as a catalyst, react at 0-5°C for 30 minutes, neutralize and concentrate after the reaction is complete Crystallized, cooled, filtered, and dried to obtain 50.5 g of prednisone hydrolyzate, the liquid phase detection content was 98.2%, and the yield was 84.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com