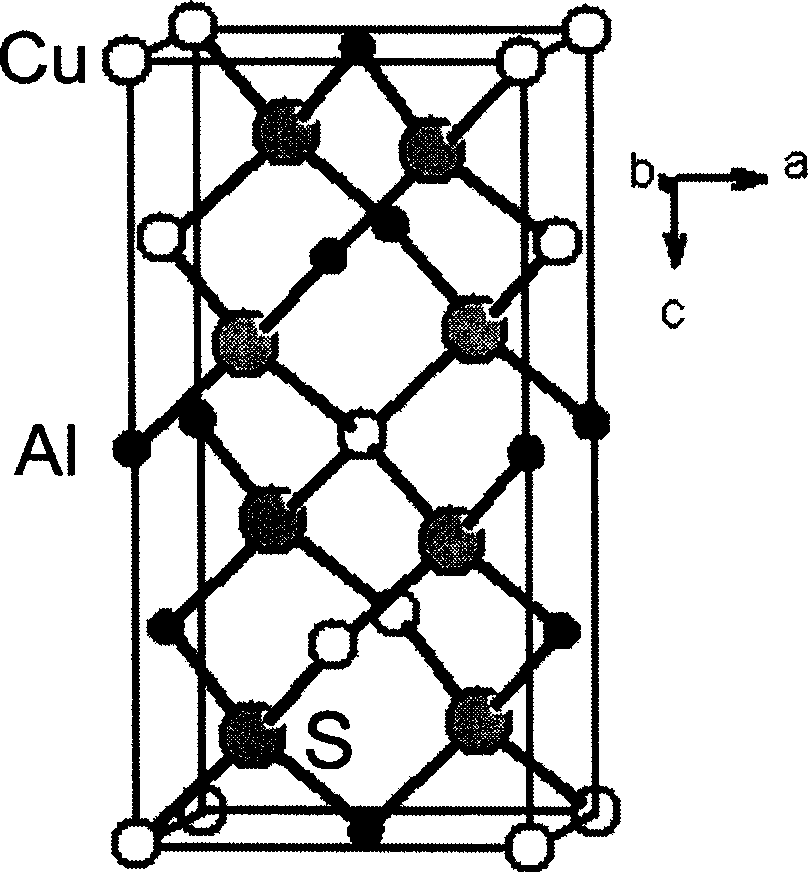

Brass ore type material for p type transparent conductor and preparing process

A chalcopyrite-type, transparent conductor technology, used in cable/conductor manufacturing, polycrystalline material growth, metal/alloy conductors, etc. Reduce the effect of local behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] According to CuAlS 2 The stoichiometric ratio is weighed and packed into a glass tube, vacuumized (less than 10 -2 Pa) and sealed with a hydrogen-oxygen flame, the glass tube containing the mixture was slowly heated to 450°C and kept for 24 hours, and then heated to 650°C to 850°C for solid phase reaction, and the reaction time was 24 to 96 hours. After the tube is opened, the powder is ground and repackaged for the second solid-state reaction, and the conditions are similar to the previous ones. The obtained pure phase powder is subjected to SPS sintering at a temperature of 700°C to 850°C and a pressure of 40 to 60 MPa to finally produce a bulk material with p-type conductivity.

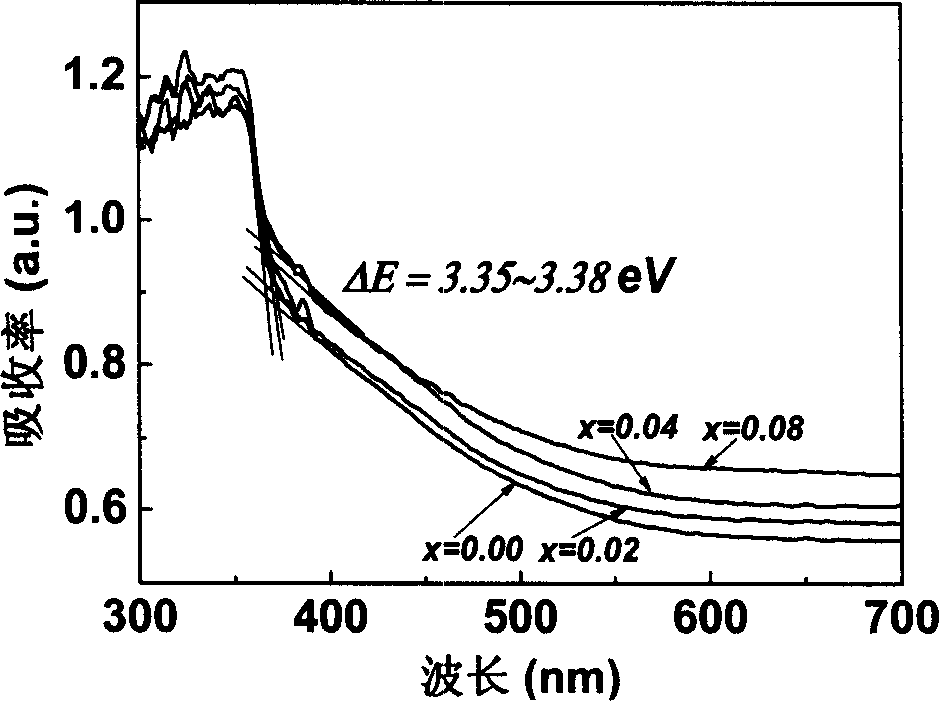

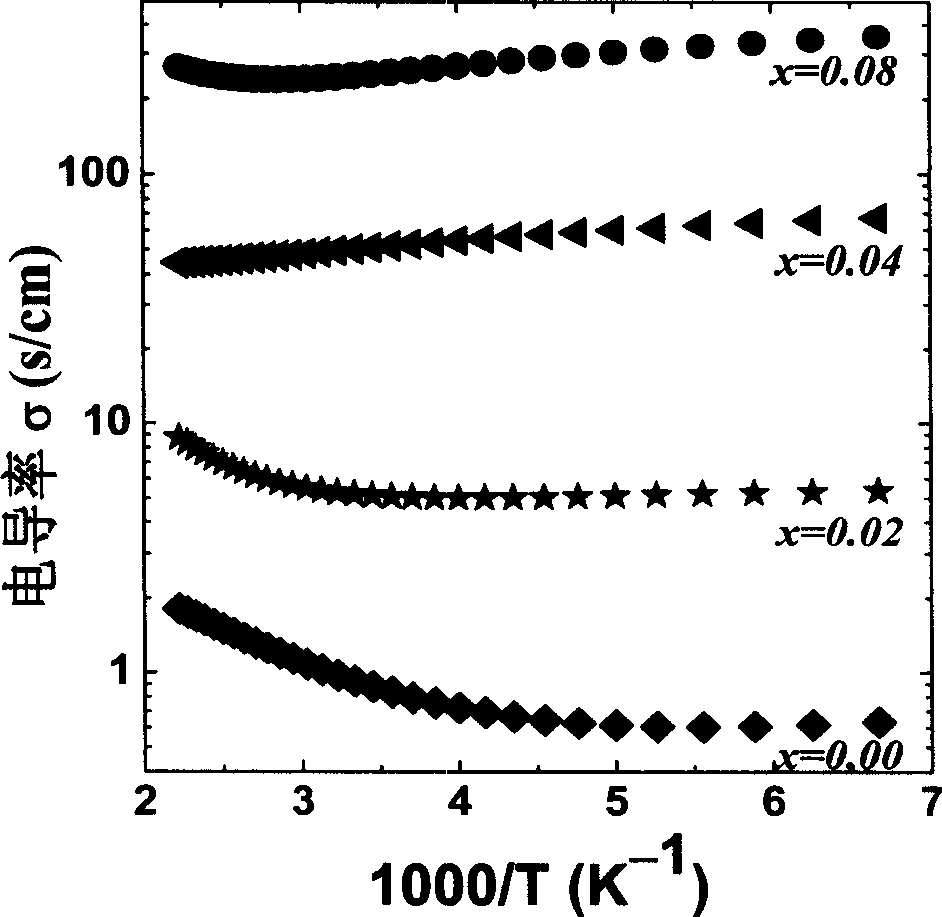

[0036] The conductivity test shows that it has p-type conductivity (the Hall coefficient and Seebeck coefficient in Table 1 are both positive), and the conductivity is good. The room temperature conductivity of the sample is about 0.9S / cm, and the conductivity curve with temperature Such a...

Embodiment 2

[0038] According to CuAlS 2 The stoichiometric ratio is weighed and packed into a glass tube, vacuumized (less than 10 -2 Pa) and sealed with a hydrogen-oxygen flame, the glass tube containing the mixture was slowly heated to 450°C and kept for 24 hours, and then heated to 650°C to 850°C for solid phase reaction, and the reaction time was 24 to 96 hours. After the tube is opened, the powder is ground and repackaged for the second solid-state reaction, and the conditions are similar to the previous ones. Put the obtained pure phase powder into a quartz glass tube after isostatic pressing at 200Mpa, and vacuumize (less than 10 -2 Pa) packaging, sintering at 700-900° C. for 6-24 hours, and finally making a bulk material with p-type conductivity for performance testing.

[0039] The performance test result is basically equivalent to that of Example 1.

Embodiment 3

[0041] Using commercially available Cu 2 S and Al 2 S 3 (purity > 99%) according to CuAlS 2 The stoichiometric ratio is weighed and packed into a glass tube, vacuumized (less than 10 -2 Pa) and sealed with a hydrogen-oxygen flame, and according to the method of embodiment 1 or embodiment 2, a bulk material with p-type conductivity is finally made.

[0042] The performance test results are basically the same as 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity at room temperature | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap