Co-current flow type deepwater current generation system and method

A flow-making and deep-water technology, which is applied in the field of parallel-flow deep-water flow-making systems, can solve the problems of waste of equipment capacity, unavailability, and limited surface flow velocity, so as to reduce equipment cost, reduce energy consumption, and improve the effect of simulated flow velocity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

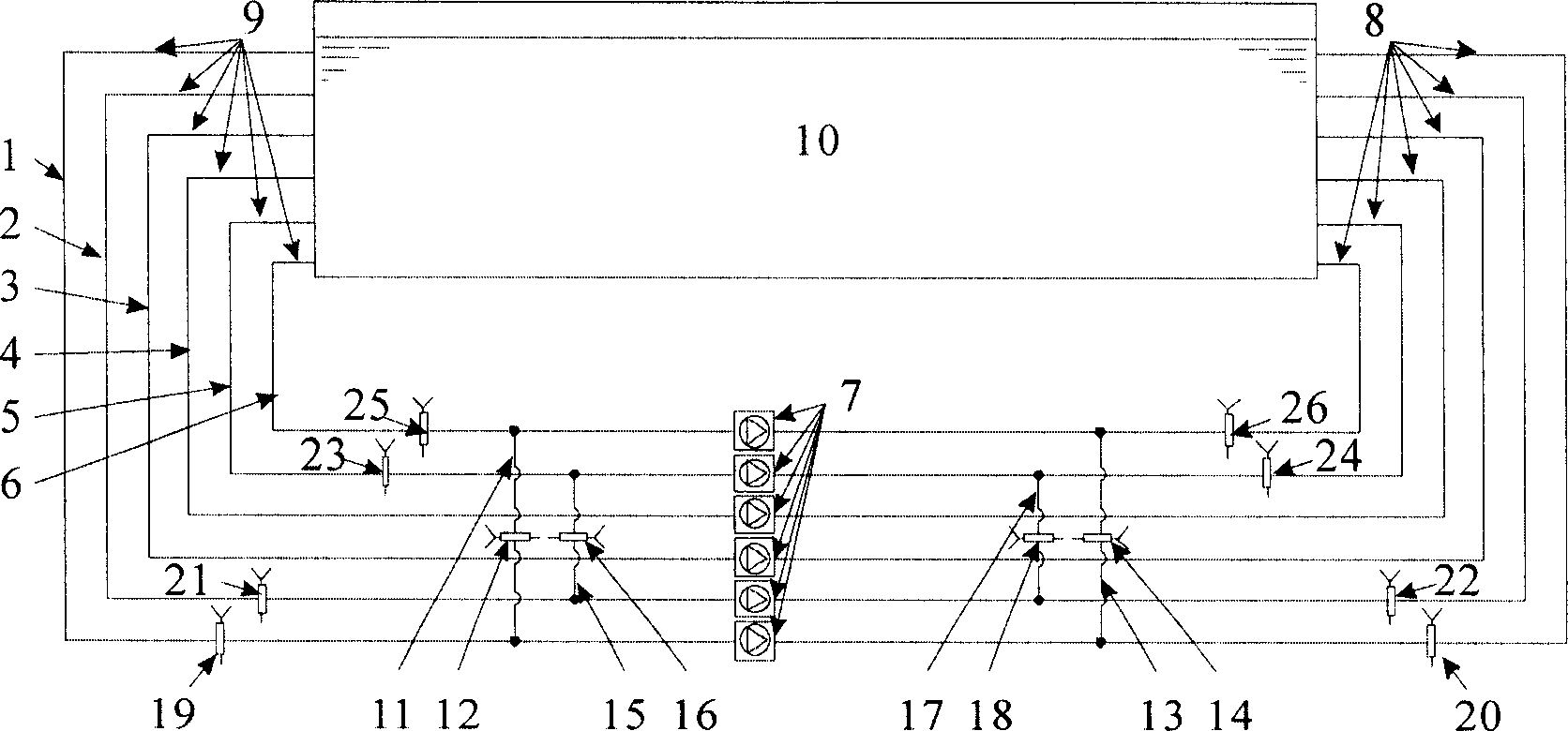

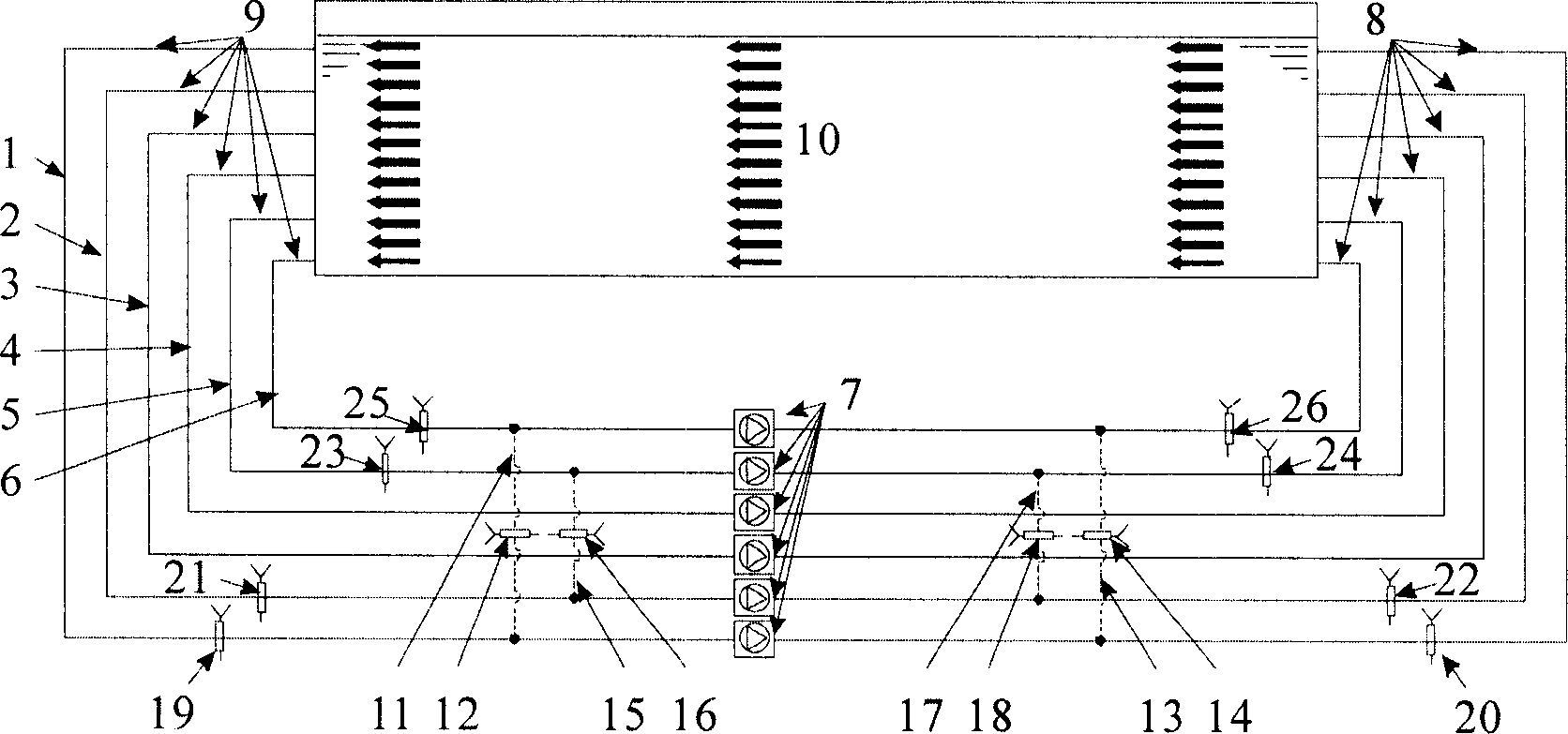

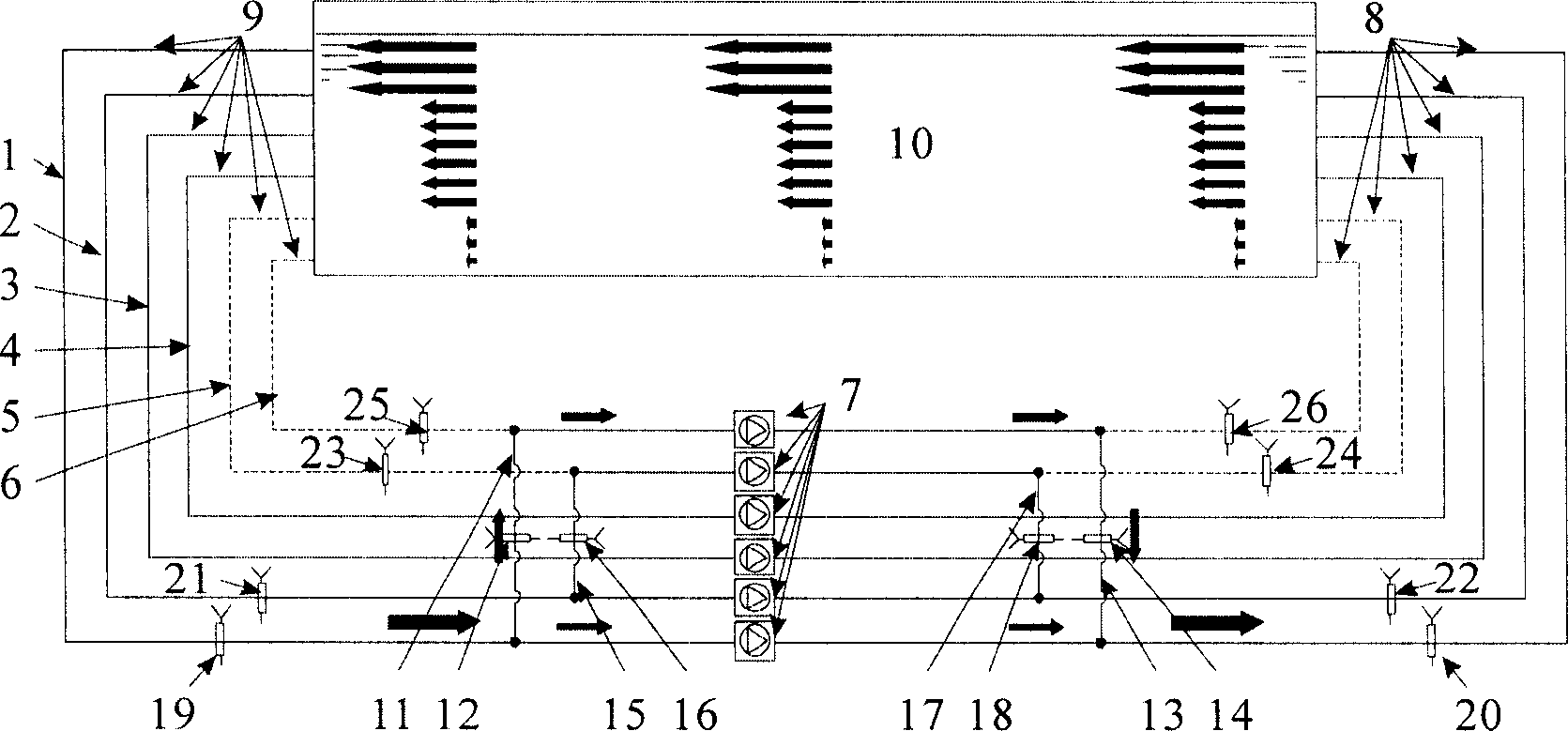

[0017] Such as figure 1 As shown, the flow-making system of the present invention includes: relatively independent six-layer flow-making devices 1, 2, 3, 4, 5, 6, and each layer of flow-making devices is composed of a driving water pump 7, a water inlet pipe 8, and a water outlet pipe 9 The water inlet pipe 8 and the water outlet pipe 9 are connected to the two ends of the pool 10, and the six-layer flow-making devices 1, 2, 3, 4, 5, and 6 are vertically arranged on the periphery of the pool 10 in order, and the flow-making device 6 is the lowest layer. , the flow-generating device 1 is the uppermost layer.

[0018] The water outlet pipes 9 of the flow generating device 1 and the flow generating device 6 are connected together through a parallel flow pipe 11 , and the water inlet pipes 8 are connected together through a parallel flow pipe 13 . The valve 12 is installed on the parallel flow pipeline 11, and the valve 14 is installed on the parallel flow pipeline 13, respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com