Method for making picture element structure

A technology of pixel structure and manufacturing method, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as breakage of reflective electrode 68, and achieve the effect of not being easily broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

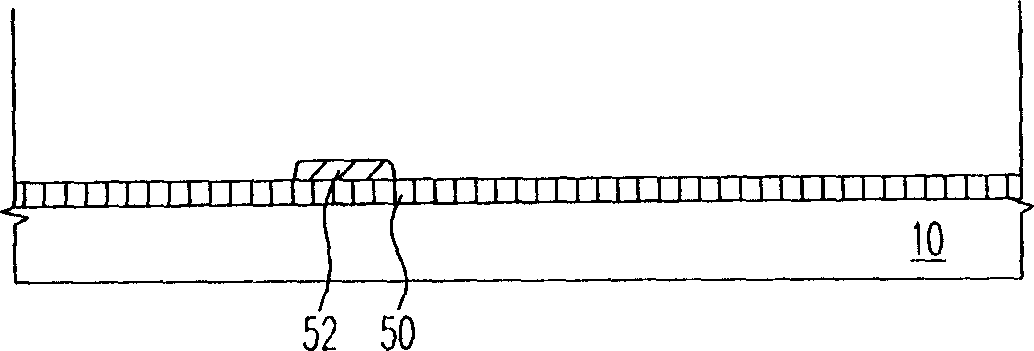

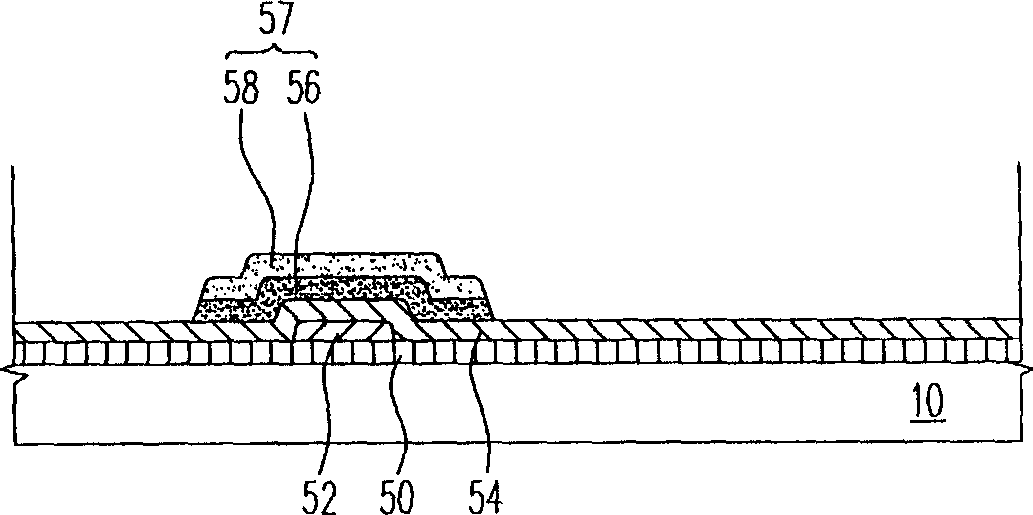

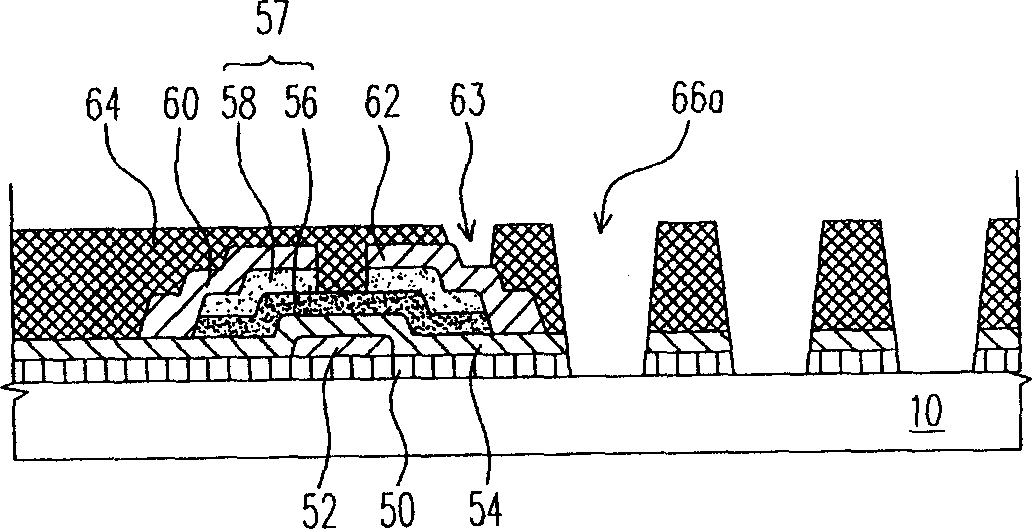

[0040] Figure 2A to Figure 2F A cross-sectional view showing a method for manufacturing a pixel structure according to a first embodiment of the present invention, and Figure 2G shows a cross-sectional view of another method for manufacturing a pixel structure according to the first embodiment of the present invention, and image 3 for Figure 2F top view. Please refer to Figure 2A and image 3 , the manufacturing method of the pixel structure of the present invention can manufacture the pixel structure for the transflective liquid crystal display panel or the total reflection liquid crystal display panel, and this embodiment will use the pixel structure of the total reflection liquid crystal display panel as Example to illustrate. The manufacturing method of the pixel structure of the present invention includes the following steps: firstly, a substrate 110 is provided, and the substrate 110 can be a glass substrate, a quartz substrate or other types of substrates. In...

no. 2 example

[0049] Figure 4A to Figure 4B A cross-sectional view showing a method for manufacturing a pixel structure according to a second embodiment of the present invention, and Figure 5 for Figure 4B top view. Figure 4C and Figure 4D A cross-sectional view illustrating another method for manufacturing a pixel structure according to the second embodiment of the present invention. Please refer to Figure 4A and Figure 5 , this embodiment is similar to the above embodiment, the difference is that in this embodiment, the method of forming the second through hole 312a and the second depression 312b is a wet etching process, so the second depression 312b can have a spherical surface shaped shape.

[0050] Please refer to Figure 4B and Figure 5 , after removing the patterned photoresist layer 210, a transparent conductor layer 160 is formed on the patterned dielectric layer 310, wherein the transparent conductor layer 160 covers and forms the second through hole 312a and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com