Multi-chip high power LED device

A light-emitting diode, high-power technology, applied in the field of semiconductors, can solve problems such as affecting luminous performance, current imbalance in parallel circuits, large thermal effects, etc., and achieve good heat dissipation performance, high luminous intensity, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

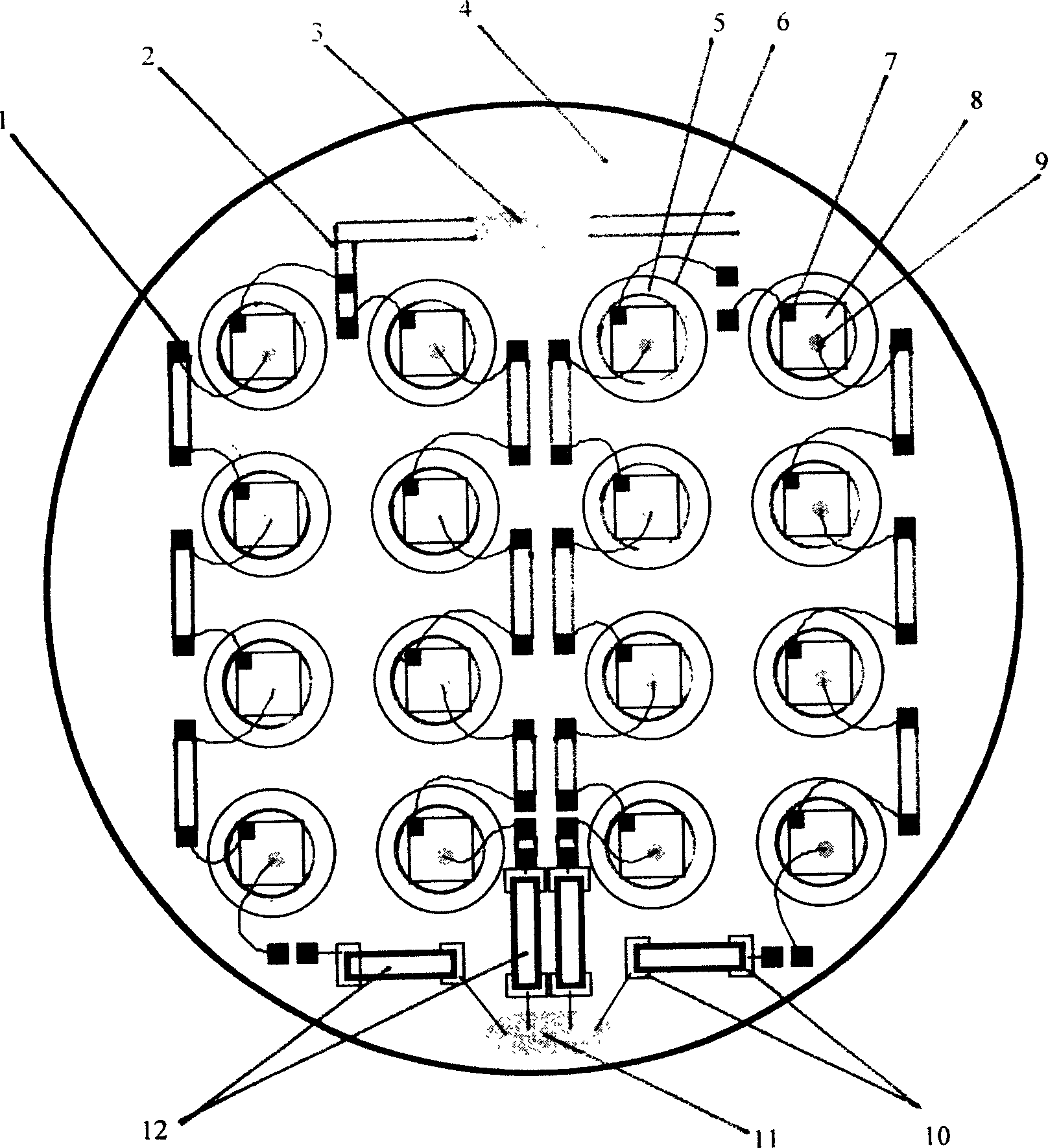

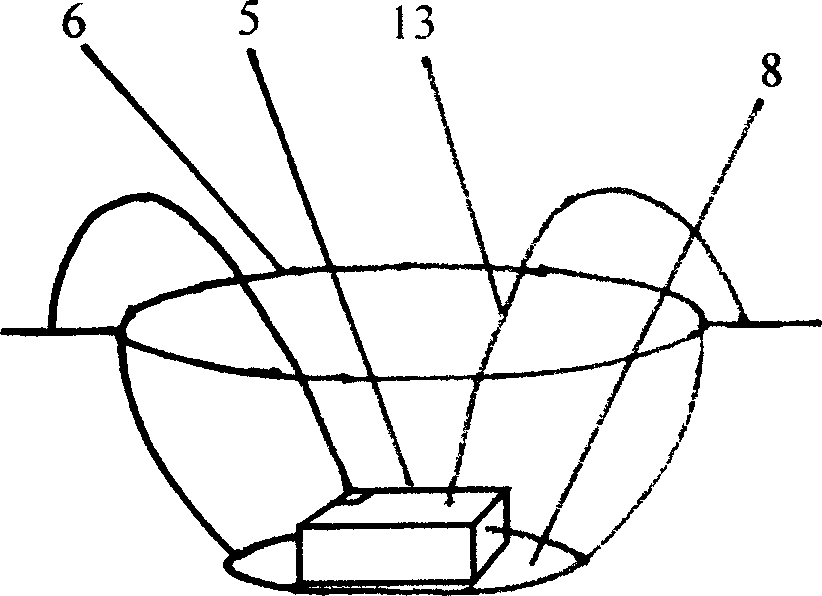

[0013] Such as figure 1 , 2 As shown, a metal substrate is used, and the cup-shaped groove 6 for installing the chip 8 is processed on the metal substrate 4, so that an LED chip 8 is installed in each cup-shaped groove 6;

[0014] Add flexible electrode plates 1 and 2 on the plane of the substrate, and the chip electrodes installed in the cup-shaped grooves are welded to the flexible electrode plates through gold wires, and the chips of a series circuit are connected in series;

[0015] Multiple light-emitting diodes in each single group are connected in series, and then connected in series with a thermistor 12 to form a series circuit composed of light-emitting diodes and thermistors, and each series circuit is connected in parallel with each other.

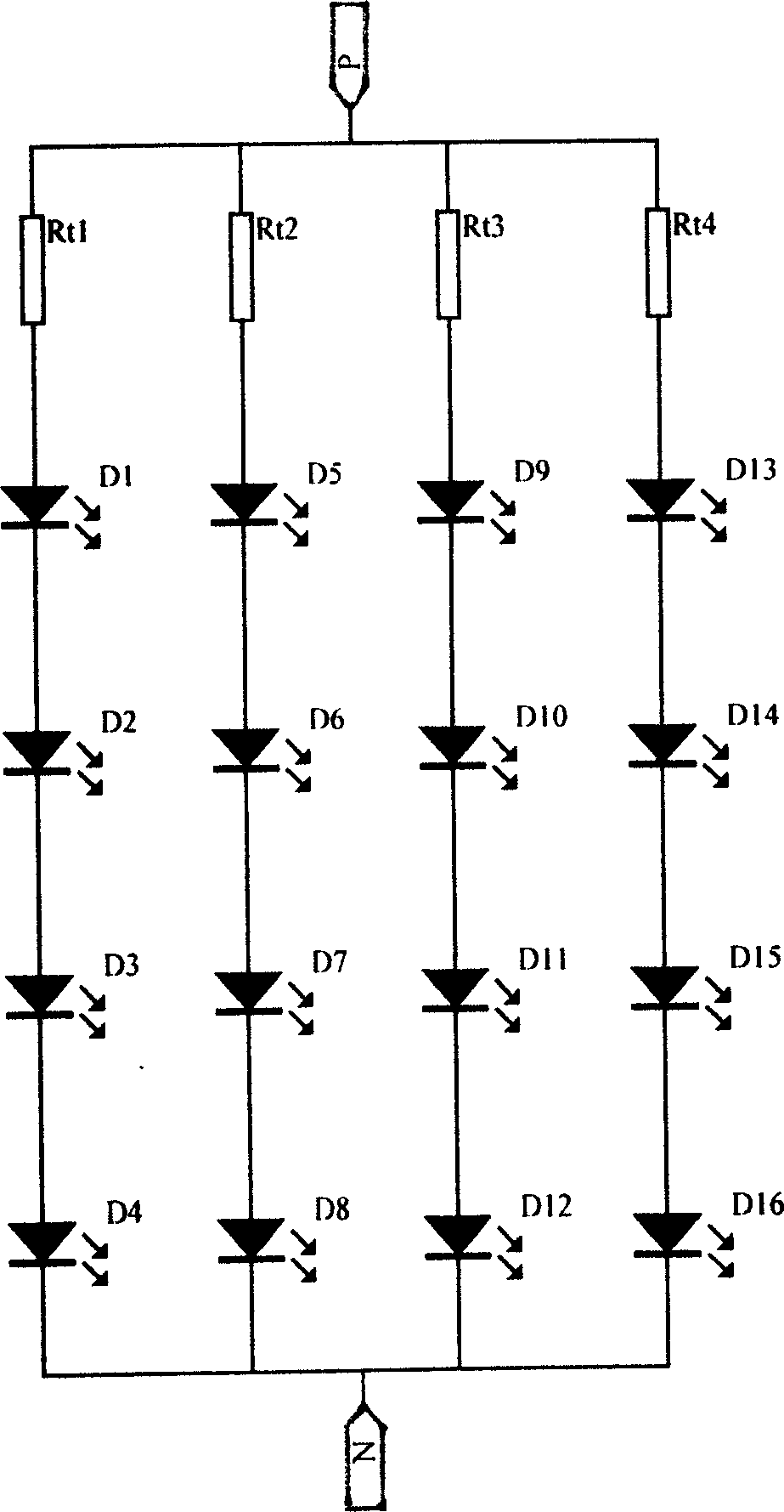

[0016] The circuit formed is as image 3 As shown, it consists of 4 sets of series circuits, the resistance Rt 1 ~Rt 4 is the thermistor, D 1 ~D 16 is the LED, the thermistor Rt 1 , LED D 1 ~D 4 Form the first series ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com