Exhaust valve return working table

A technology of rotary workbench and exhaust valve, which is applied to the necessary equipment for repair and maintenance, disassembly and assembly of exhaust valve components of diesel engines, and the field of exhaust valve rotary workbench, which can solve the problem of damage to screw holes and insufficient overall structural strength and rigidity , small space height and other issues, to achieve the effect of labor-saving operation, high strength and rigidity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below in conjunction with accompanying drawing and embodiment the present invention will be further described, but should not limit protection scope of the present invention with this:

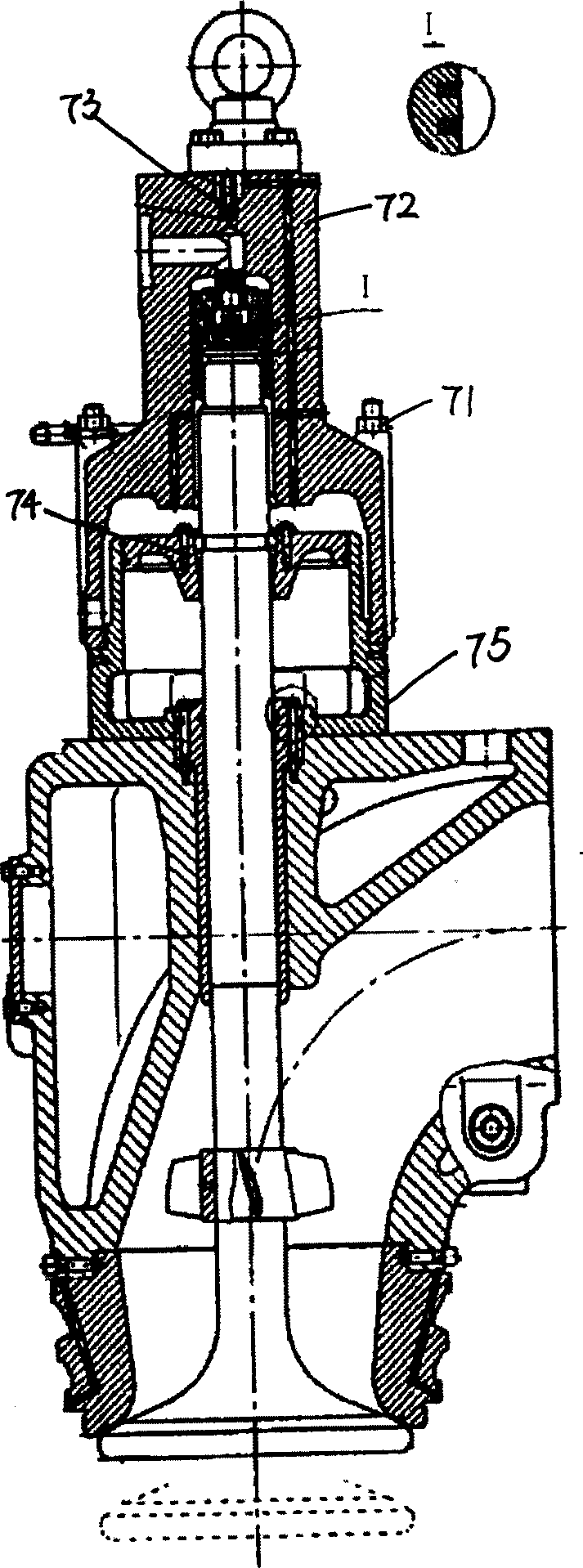

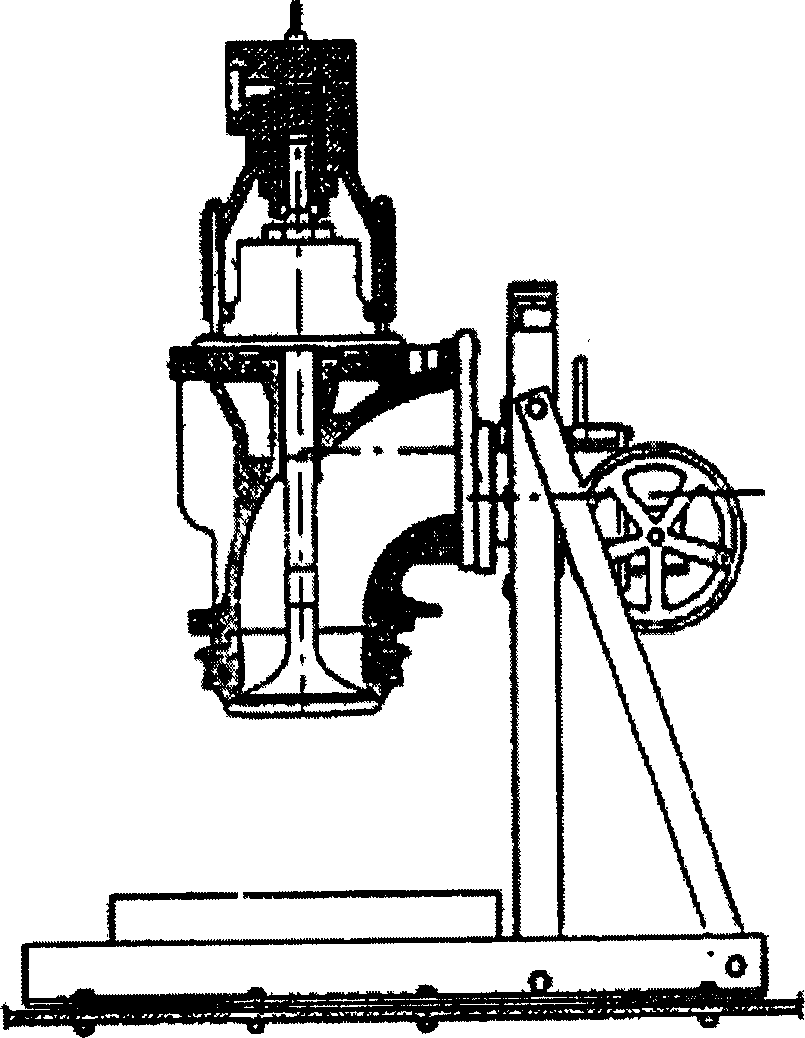

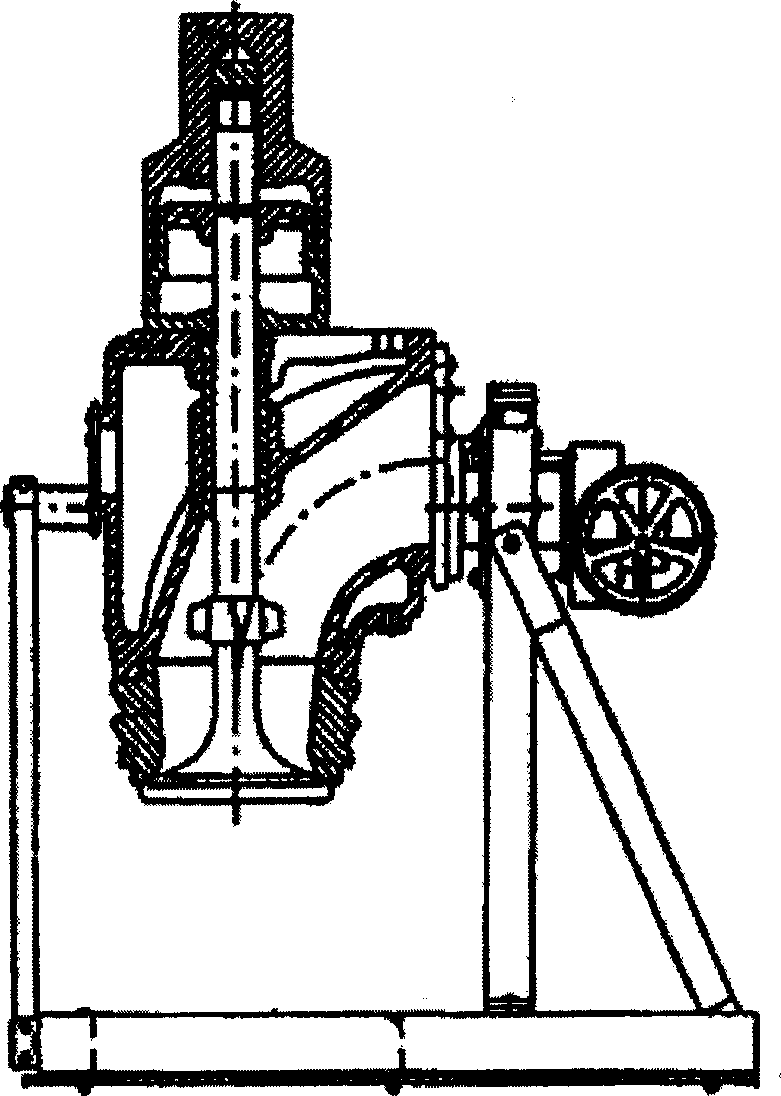

[0063] see first Figure 4 , Figure 5 , Image 6 with Figure 7 , Figure 4 , Figure 5 with Image 6 It is a structural schematic diagram of a specific embodiment of the present invention. It can be seen from the figure that the exhaust valve rotary table of the present invention includes a rotary frame 1, a transmission mechanism 2 and a support 3. The rotary frame 1 is composed of two end plates 11, a The base plate 12, the two side plates 14, and the rigid frame formed by the shaft extensions 16 at both ends are fixed. The base plate 12 has a central through hole 121 for installing the exhaust valve. There are four pillars 13 on the ground, and there are pillar screw holes 131 on the top of the pillars 13, and there are four long studs 15 correspondingly. 11 is centered on t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap