Jp2006234470

An inspection method and an inspection device technology, applied to disk-shaped record carriers, optics, instruments, etc., can solve the problems of deviation of inspection results, inability to fully remove netting, deviation of color moiré inspection results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

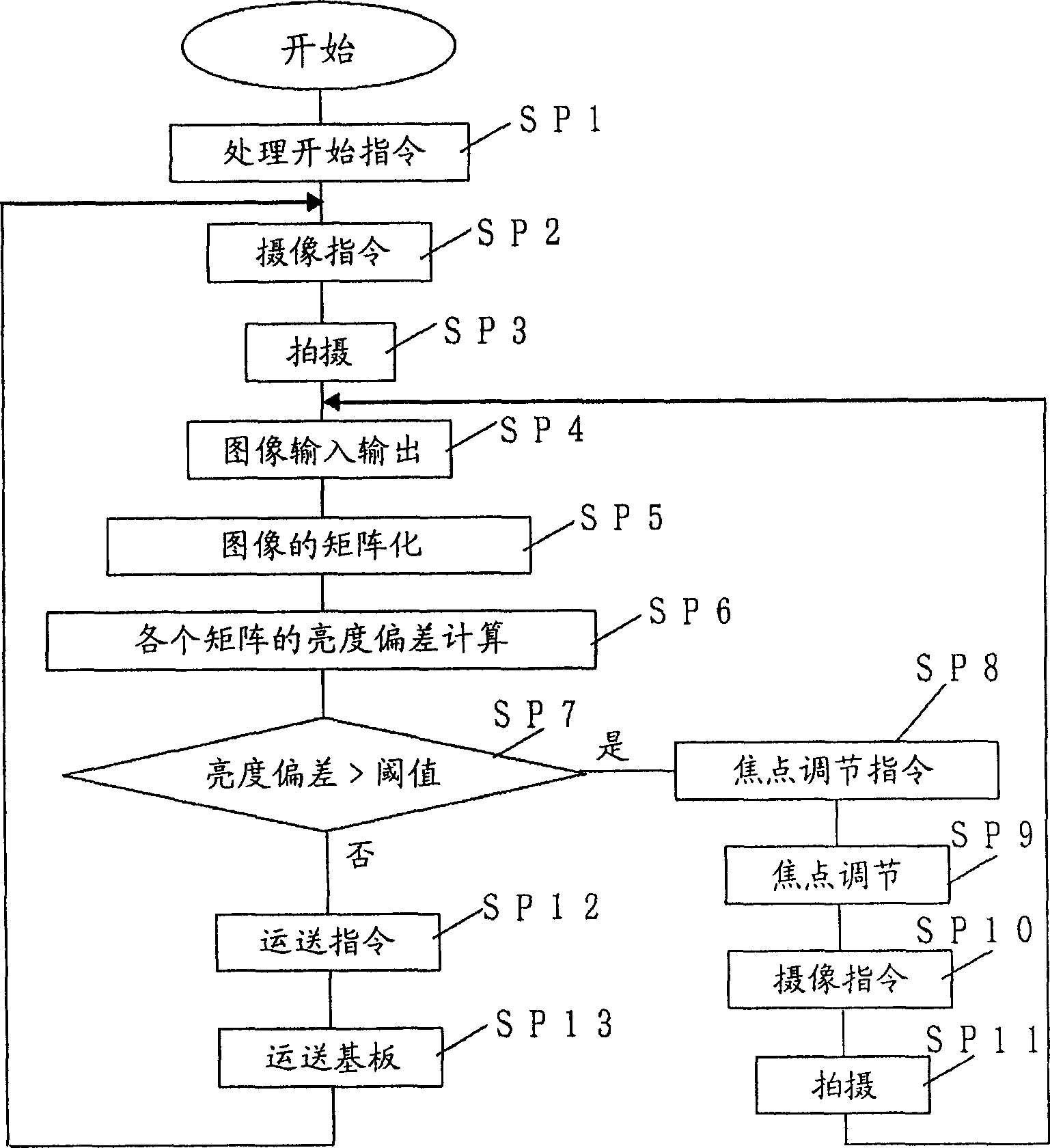

[0031] Hereinafter, embodiments of the color moiré inspection method and device thereof according to the present invention will be described in detail with reference to the drawings.

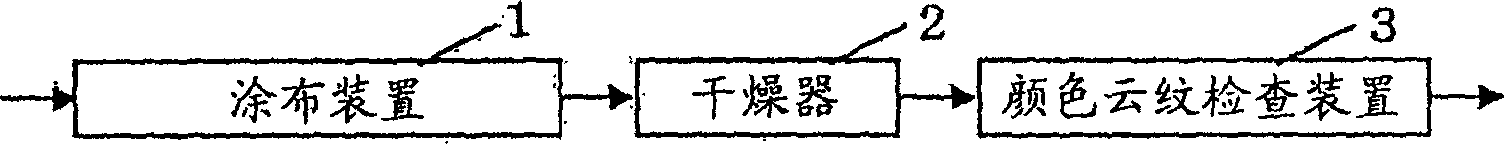

[0032] figure 1 It is a schematic diagram showing main parts of a color filter manufacturing apparatus for flat panel displays to which the color moiré inspection method of the present invention is applied.

[0033] This color filter manufacturing apparatus includes: a coating device 1 for coating a light-transmitting color coating on a light-transmitting substrate such as glass; and a dryer 2 for drying the coated color coating. and a color moiré inspection device 3 for inspecting the presence, degree, position, etc. of color moiré of the dried color film.

[0034] For example, a color filter is formed by arranging at least three primary colors in a matrix, so a coating device 1 , a dryer 2 , and a color moiré inspection device 3 are provided for each color.

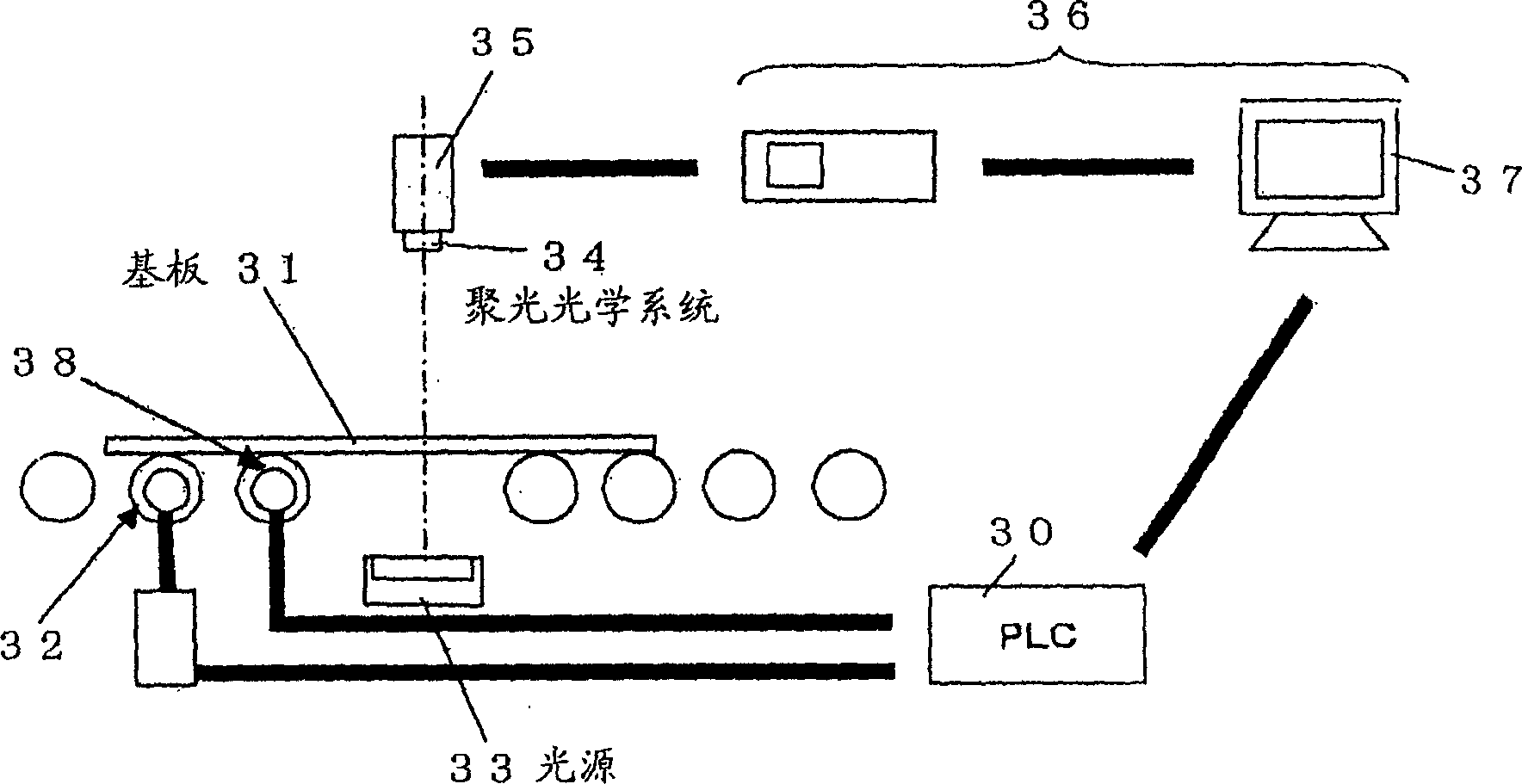

[0035] figure 2 It is a schema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com