Differential force type magnetic suspension water level gauge

A technology of magnetic levitation and water level gauge, which is applied in the direction of buoy liquid level indicator, etc., can solve the problems of easy leakage, lag, and reduced measurement accuracy of ground water level gauge, and achieve the effect of not easy to leak and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

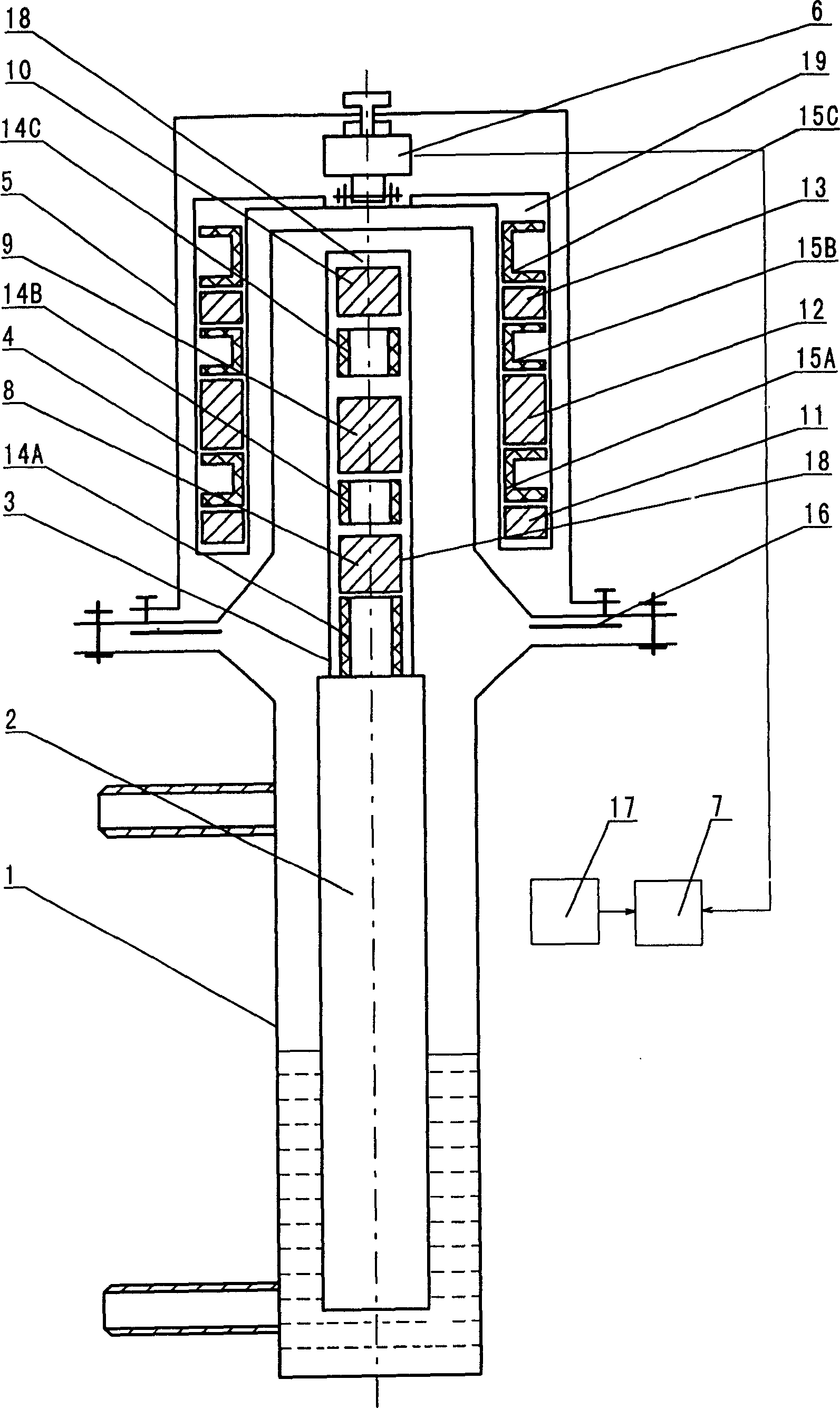

[0008] The present invention as figure 1 As shown, a cylindrical structure is adopted, and the upper straight pipe section of the container 1 is connected with the lower part of the container 1 by a flange connection, and the joint is sealed with an annular gasket 16 .

[0009] The measuring hammer 2 is columnar and placed vertically in the container 1 . The inner magnetic steel assembly 18 includes inner magnetic steel columns 8, 9, 10, the three are cylindrical, stacked in the inner magnetic steel sheath 3, and separated by annular spacers 14A, 14B, 14C, the inner magnetic steel sheath The lower end of the sleeve 3 is welded to the upper end of the measuring hammer 2 . The lower end of the support 5 is also connected with the straight pipe section of the container 1 in the form of a flange. The upper end of the tension transmitter 6 is fixed on the bracket 5 with bolts, and the measuring end is connected with the outer magnetic steel sheath 4 with connecting bolts. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com