Detection device for adhesion amount of color toner

A measuring device and a technology for adhesion amount, which are applied in scattering characteristics measurement, electrography, polarization influence characteristics, etc., can solve the problems of increased component cost and assembly cost, increased number of processes, deviation of measurement accuracy, etc., so as to improve the installation Accuracy, realization of compact structure, and effect of reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

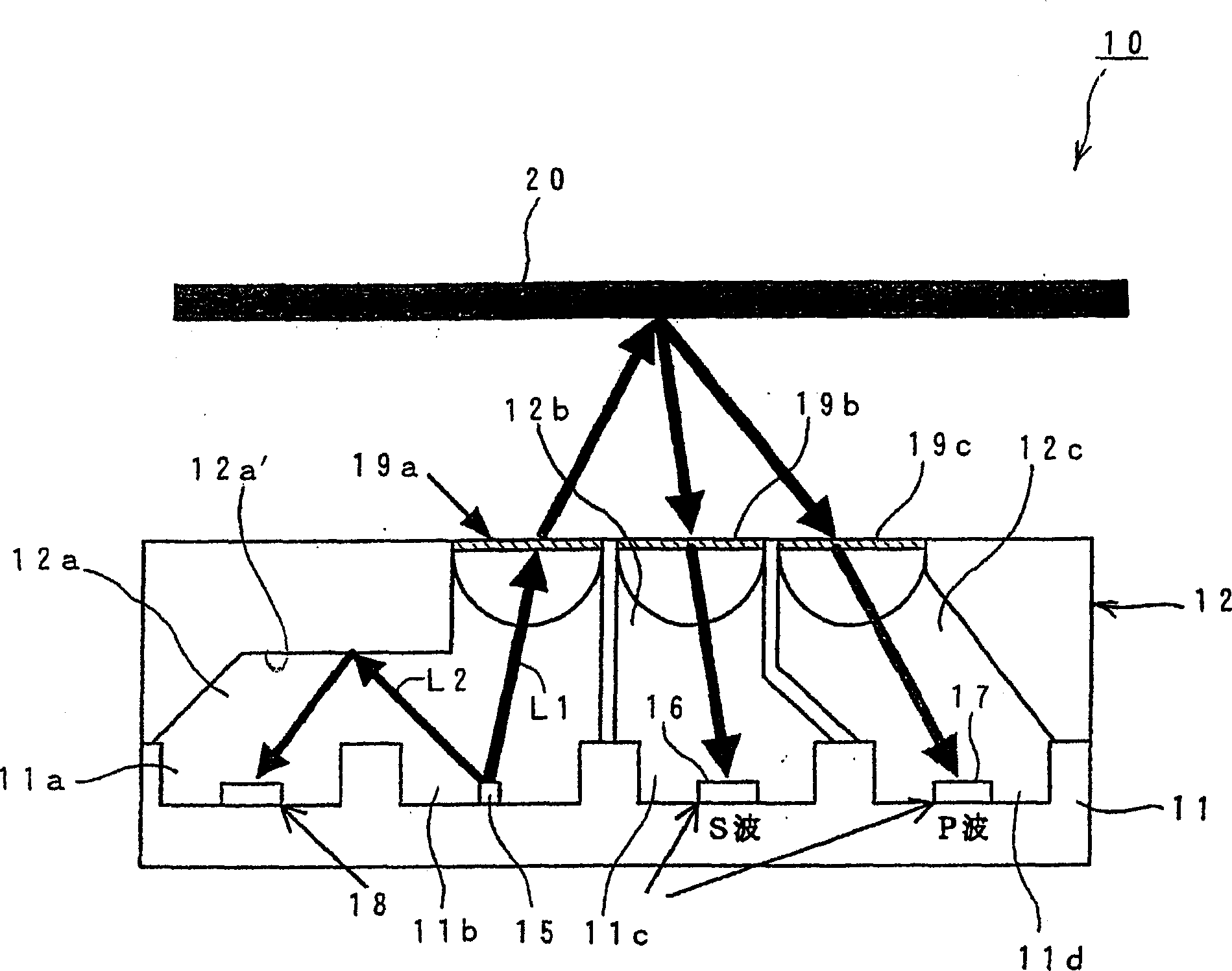

[0057] figure 1 The structure of one embodiment of the color toner adhesion measuring device of the present invention is shown.

[0058] exist figure 1 Among them, the color toner adhesion measurement device 10 includes a frame member 11 and a cover 12 .

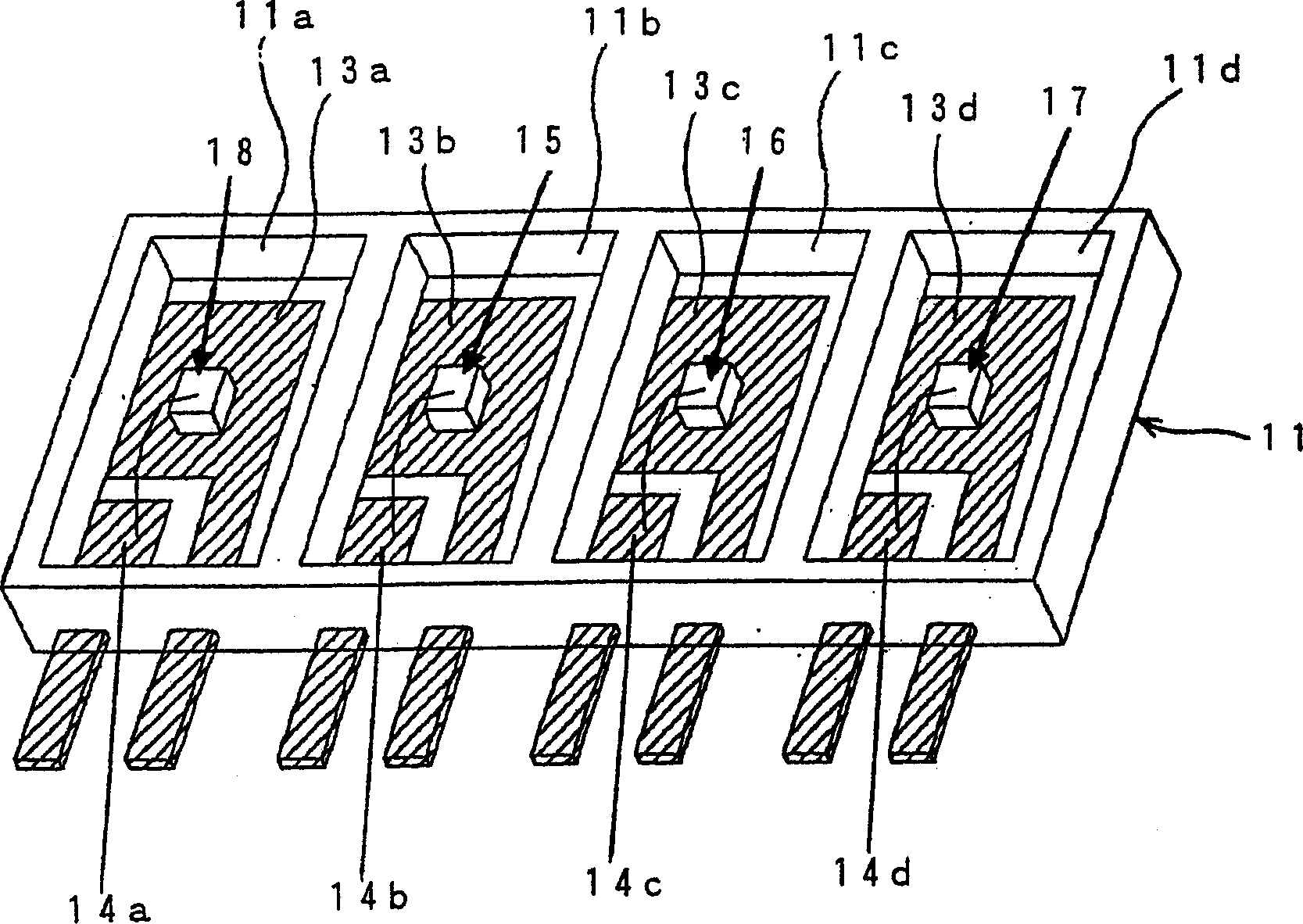

[0059] The frame member 11 is formed in a flat rectangular parallelepiped shape made of resin, and has four depressed portions 11a, 11b, 11c, and 11d arranged in a row.

[0060] In each recessed portion 11a, 11b, 11c, 11d, as figure 2 As shown, there are respectively a pair of conductive parts 13a, 14a, 13b, 14b, 13c, 14c and 13d, 14d facing each other and exposed on their bottom surfaces.

[0061] These conductive parts 13a, 14a, 13b, 14b, 13c, 14c and 13d, 14d are integrally formed with the frame member 11 by, for example, insert molding, and the other ends protrude from one side of the frame member 11 to form lead terminals.

[0062] Here, if figure 1 and figure 2 As shown, in the second concave portion 11b, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com