Apparatus and method for online monitoring pH value in MES production

A ph value, ph meter technology, applied in the direction of ratio control, chemical variable control, non-electric variable control, etc., can solve the problems of pH value failure of the system, increase of freezing point, misleading operators, etc., to ensure product quality and safe production, The effect of ensuring product quality and safe production, improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

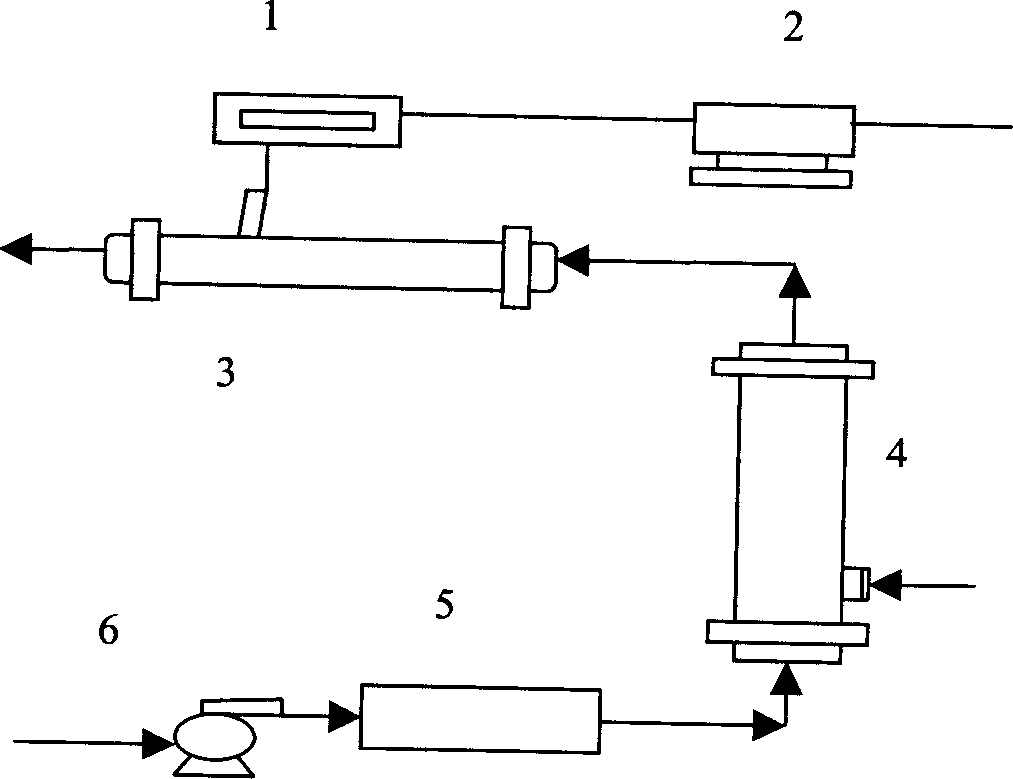

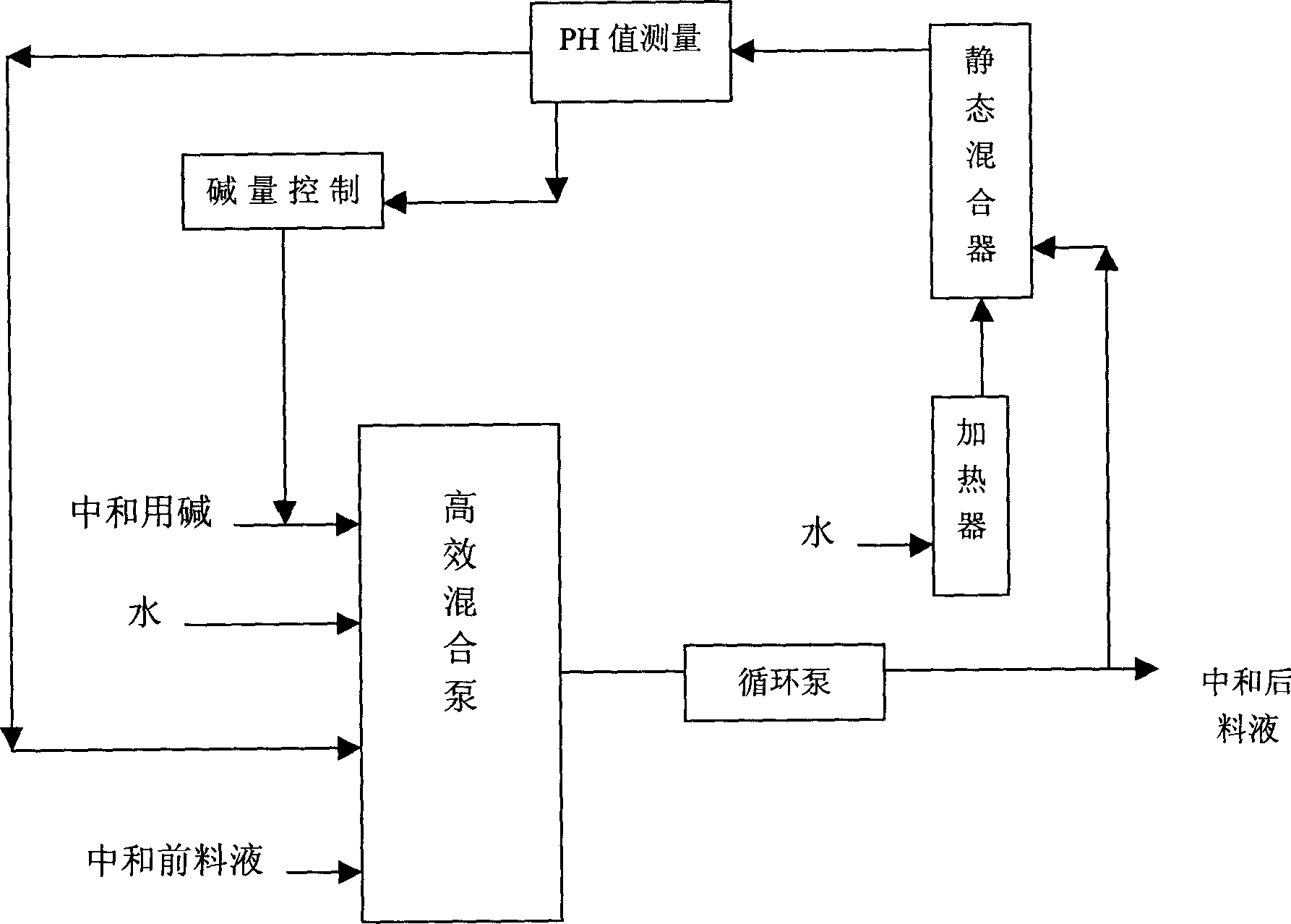

[0024] Divert a small amount of materials from the main line or mixer of the neutralization system to the static mixer. At the same time, use a pump to pump water (the ratio of material to water: 0.1-15: 100) and heat it to the required temperature (25 ℃~50℃) and then enter the static mixer. The evenly mixed diluted material enters the fluid tube inserted with the pH measuring electrode. The pH value is displayed on the pH meter, and the electrical signal is transmitted to the alkali quantity controller by the computer. The program controls the alkali used for neutralization, and the diluent flowing out of the fluid pipe is returned to the feed pipe before neutralization to complete a cycle to achieve the purpose of accurate measurement and control of the pH value of the neutralization system.

Embodiment 2

[0026] Divert a small amount of material from the main line or mixer of the neutralization system to the static mixer, and at the same time use a pump to pump water (the ratio of material to water: 0.5:100) and heat it to the desired temperature (35°C) by a heater Then enter the static mixer, the evenly mixed diluent enters the fluid tube inserted with the pH measuring electrode, the pH value is displayed on the pH meter, and the electrical signal is transmitted to the alkali quantity controller by the computer program to control the neutralization. Alkali, the diluent flowing out of the fluid pipe is returned to the feed pipe before neutralization to complete a cycle to achieve the purpose of accurate measurement and control of the pH value of the neutralization system.

Embodiment 3

[0028] Divide a small amount of material from the main line or mixer of the neutralization system to the static mixer, and at the same time use a pump to pump water (the ratio of material to water: 5.0:100) and heat it to the desired temperature (25°C) by a heater Then enter the static mixer, the evenly mixed diluent enters the fluid tube inserted with the pH measuring electrode, the pH value is displayed on the pH meter, and the electrical signal is transmitted to the alkali quantity controller by the computer program to control the neutralization. Alkali, the diluent flowing out of the fluid pipe is returned to the feed pipe before neutralization to complete a cycle to achieve the purpose of accurate measurement and control of the pH value of the neutralization system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com